Graphene-activated carbon composite filter element as well as preparation method and application thereof

A composite filter element and graphene technology, applied in the field of water filtration and purification, can solve the problems of affecting human health, the filtration effect cannot be further improved, membrane pollution, etc., and achieve excellent heavy metal removal effect, increase adhesion effect, and improve the effect of taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment provides a kind of preparation method of graphene-activated carbon composite filter core, comprises the steps:

[0057] Step 1. Preparation of raw materials: graphene powder is prepared by oxidation-reduction method, and the monolayer ratio of the selected graphene is 85-95%.

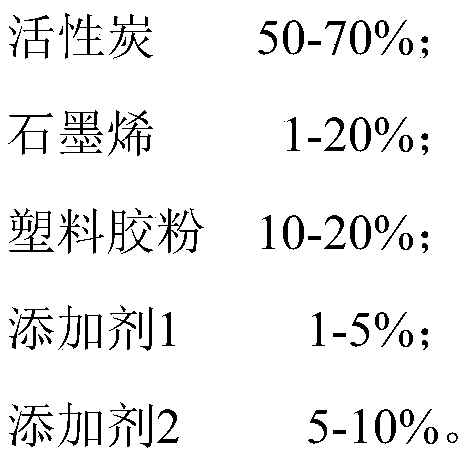

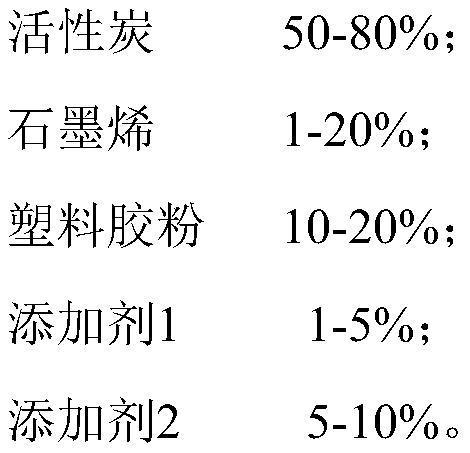

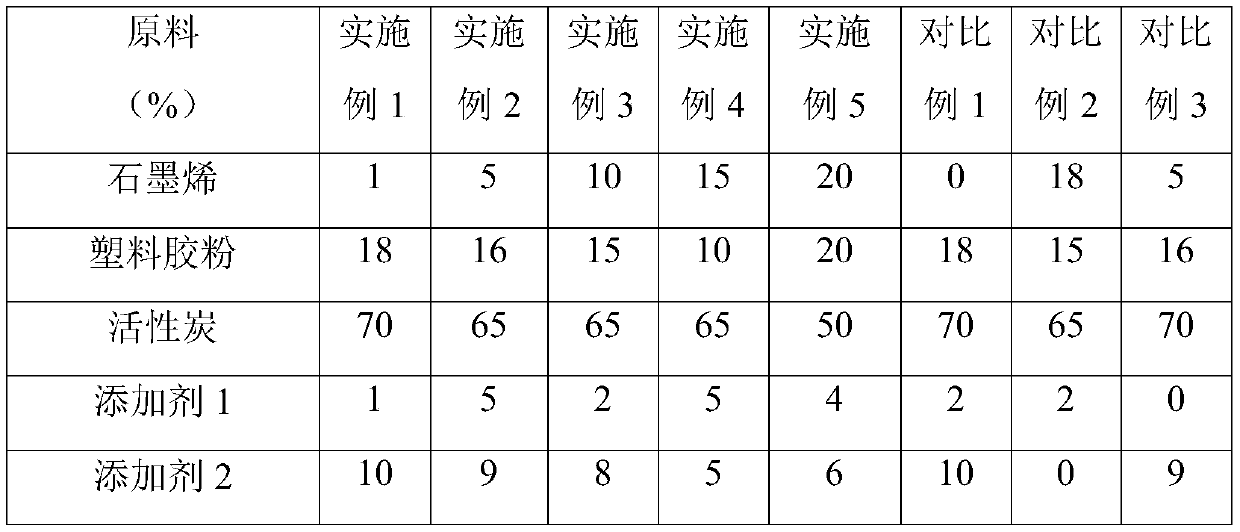

[0058] Step 2. Surface compounding: Mix coconut shell activated carbon powder, plastic rubber powder and graphene powder for pre-grafting, add additive 1 (mass ratio of zeolite beta to ceramic is 1:0.5), mix evenly, and then add additive 2 (the mass ratio of food-grade cationic sodium exchange resin and chelating resin is 1:1), continue to stir evenly. The mass percentage of each component is shown in Table 1.

[0059] Step 3. Extrusion molding: Pour the mixed carbon powder into the compressed activated carbon filter production equipment, after full stirring, heat up to 100-160 degrees Celsius, carry out graft modification treatment, extrude, and cut into a certain length ...

Embodiment 2

[0062] The present embodiment provides a kind of preparation method of graphene-activated carbon composite filter core, comprises the steps:

[0063] Step 1. Preparation of raw materials: graphene powder is prepared by oxidation-reduction method, and the monolayer ratio of the selected graphene is 85-95%.

[0064] Step 2. Surface compounding: Mix coconut shell activated carbon powder, plastic rubber powder and graphene powder for pre-grafting, add additive 1 (the mass ratio of beta zeolite to calcite is 1:1), mix evenly, and then add the additive 2 (the mass ratio of food-grade cationic sodium exchange resin to mixed bed polishing resin is 1:2), and continue to stir evenly to obtain a mixture. The mass percentage of each component is shown in Table 1.

[0065] Step 3. Extrusion molding: Pour the mixture into the compressed activated carbon filter element production equipment, after full stirring, heat up to 100-160 degrees Celsius, carry out graft modification treatment, extr...

Embodiment 3

[0068] The present embodiment provides a kind of preparation method of graphene-activated carbon composite filter core, comprises the steps:

[0069] Step 1. Preparation of raw materials: graphene powder is prepared by oxidation-reduction method, and the monolayer ratio of the selected graphene is 85-95%.

[0070] Step 2. Surface compounding: Mix coconut shell activated carbon powder, plastic rubber powder and graphene powder for pre-grafting, add additive 1 (the mass ratio of zeolite beta to tourmaline is 1:0.8), mix well, and then add Additive 2 (the mass ratio of food-grade cationic sodium exchange resin to strongly basic anion exchange resin is 1:3), and continue to stir evenly. The mass percentage of each component is shown in Table 1.

[0071] Step 3. Extrusion molding: Pour the mixed carbon powder into the compressed activated carbon filter production equipment, after full stirring, heat up to 100-160 degrees Celsius, carry out graft modification treatment, extrude, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com