A high-efficiency heterojunction photocatalyst using nise as an auxiliary agent and its preparation method and application

A photocatalyst and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve problems such as high cost, achieve rich applications, simple preparation process, and promote hydrogen production activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation steps of the present invention are as follows:

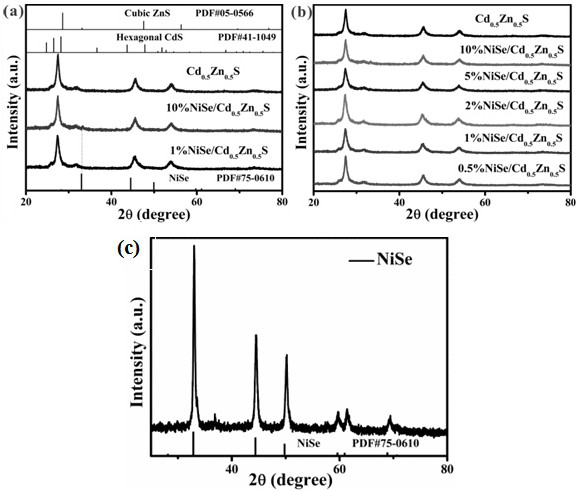

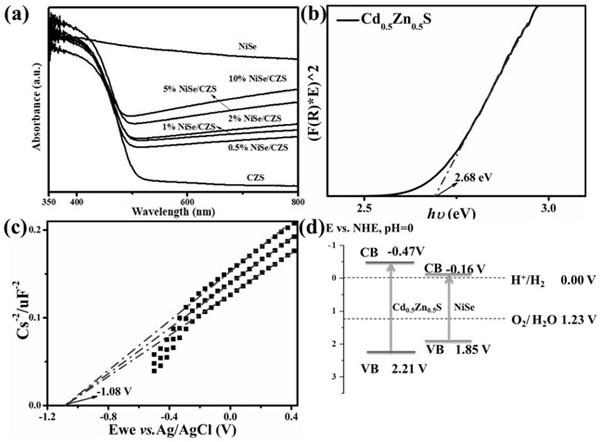

[0017] Cd 0.5 Zn 0.5 Preparation of S solid solution: Weigh 10 mmol of cadmium acetate·dihydrate and 10 mmol of zinc acetate·dihydrate into a 100 mL reaction kettle liner, add 40 mL of deionized water and stir to dissolve, and then magnetically Under stirring, 10 mL of 4 mol / L NaOH aqueous solution was added dropwise to the above solution with a pipette, and the solution gradually turned into a white viscous paste. After stirring for 30 minutes, 25 mmol of thioacetamide was added to the solution with stirring. the above solution. The reaction mixture gradually turned yellow, after which it was stirred again for 30 minutes, then it was sealed in an autoclave, heated to 180°C in an electric blast drying oven, and held for 24 hours. After cooling to room temperature, the precipitate was centrifuged, washed several times with water and ethanol, and dried in a vacuum oven at 80°C for 8 hours to obtain Cd 0....

Embodiment 1

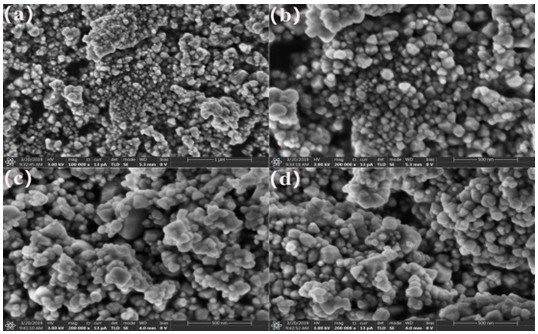

[0020] A certain amount of nickel sulfate hexahydrate and sodium selenite (14.53 μmoL) were dissolved in 40 mL of ethylene glycol solvent in a molar ratio of 1:1, and then a certain amount of Cd was added. 0.5 Zn 0.5 S solid solution (40 mg) was stirred uniformly and then transferred to the autoclave, kept at 180 °C for 24 hours, and finally cooled to room temperature naturally. The obtained samples were centrifuged and washed with deionized water and absolute ethanol, and dried in a vacuum oven to obtain NiSe / Cd with a NiSe loading of 0.5%. 0.5 Zn 0.5S heterojunction photocatalyst. Accurately weighed 10 mg of the synthesized powder catalyst was placed in a photo-splitting water reactor to test the hydrogen production performance of photo-splitting water.

Embodiment 2

[0022] Dissolve a certain amount of nickel sulfate hexahydrate and sodium selenite (29.06 μmoL) in 40 mL of ethylene glycol solvent at a molar ratio of 1:1, and then add a certain amount of Cd 0.5 Zn 0.5 S solid solution (40 mg), stirred evenly, transferred to a high-pressure reactor, kept at 180°C for 24 hours, and finally cooled down to room temperature naturally. The obtained samples were washed by centrifugation with deionized water and absolute ethanol, and dried in a vacuum oven to obtain NiSe / Cd with a NiSe loading of 1%. 0.5 Zn 0.5 S heterojunction photocatalyst. Accurately weighed 10 mg of the synthesized powder catalyst was placed in a photo-splitting water reactor to test the hydrogen production performance of photo-splitting water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com