Defect type covalent triazine framework material derivative material catalyst and preparation method and application thereof

A technology of covalent triazine and framework materials, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems that the catalytic activity of catalysts needs to be improved, and achieve good catalytic cycle stability and high Effect of low specific surface area and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

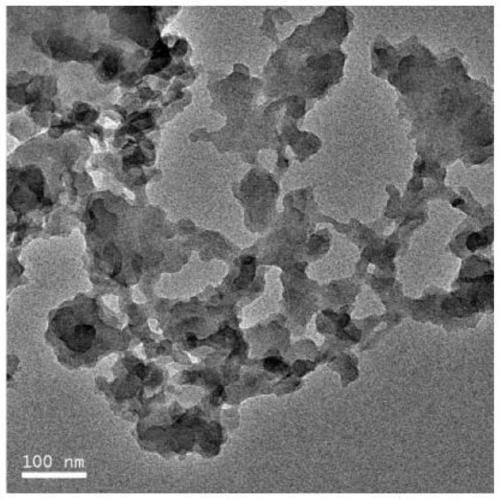

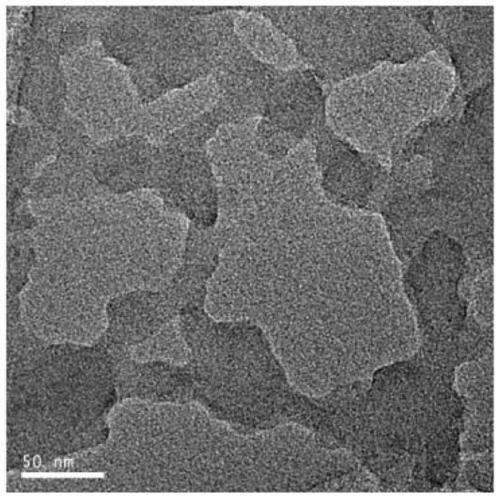

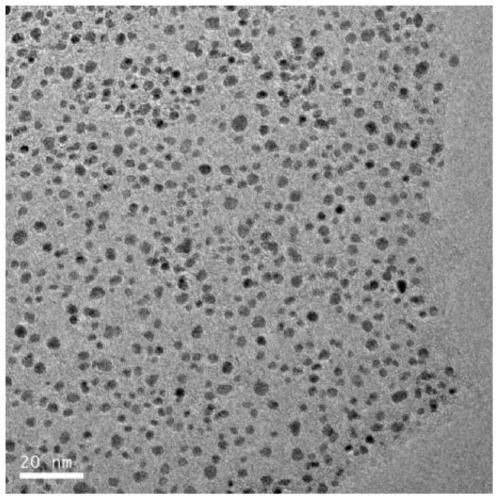

Image

Examples

Embodiment 1

[0034] 1) Dissolve 0.64g of terephthalonitrile and 0.64g of 2,6-pyridinedicarbonitrile in 60mL of dichloromethane organic solvent, stir and fully dissolve at room temperature to obtain a dispersion;

[0035] 2) Put the dispersion liquid obtained in step 1) into a round bottom flask, set it in an oil bath, add 10mL of trifluoromethanesulfonic acid, heat to reflux, and stir at 60°C for 40h. After the reaction, put The reaction solution was cooled to room temperature;

[0036]3) Pour the cooled reaction solution in step 2) into a beaker containing 200mL of ultrapure water, and use a pipette to add concentrated ammonia water (the concentration of concentrated ammonia water is 0.5mol / L) drop by drop to adjust the pH value of the solution to 7. Suction filtration is then carried out, and the filter residue is washed with dichloromethane, ultrapure water and ethanol in sequence, and dried in vacuum to finally obtain the defective covalent triazine framework carrier material powder; ...

Embodiment 2

[0043] 1) Dissolve 0.64g of terephthalonitrile and 0.64g of 2,6-pyridinedicarbonitrile in 60mL of dichloromethane organic solvent, stir and fully dissolve at room temperature to obtain a dispersion;

[0044] 2) Put the dispersion obtained in step 1) in a round bottom flask, put it in an oil bath, add 10mL of trifluoromethanesulfonic acid, heat to reflux, and stir at 60°C for 40h. After the reaction, put The reaction solution was cooled to room temperature;

[0045] 3) Pour the cooled reaction solution in step 2) into a beaker containing 200mL of ultrapure water, and use a pipette to add concentrated ammonia water (the concentration of concentrated ammonia water is 0.5mol / L) drop by drop to adjust the pH value of the solution to 7. Suction filtration is then carried out, and the filter cake is washed with dichloromethane, ultrapure water and ethanol in sequence, and dried in vacuum to finally obtain the defective covalent triazine framework carrier material powder;

[0046] 4)...

Embodiment 3

[0049] 1) Dissolve 0.64g of terephthalonitrile and 0.64g of 2,6-pyridinedicarbonitrile in 60mL of dichloromethane organic solvent, stir and fully dissolve at room temperature to obtain a dispersion;

[0050] 2) Put the dispersion obtained in step 1) in a round bottom flask, put it in an oil bath, add 10mL of trifluoromethanesulfonic acid, heat to reflux, and stir at 60°C for 40h. After the reaction, put The reaction solution was cooled to room temperature;

[0051] 3) Pour the cooled reaction solution in step 2) into a beaker containing 200mL of ultrapure water, and use a pipette to add concentrated ammonia water (the concentration of concentrated ammonia water is 0.5mol / L) drop by drop to adjust the pH value of the solution to 7. Suction filtration is then carried out, and the filter cake is washed with dichloromethane, ultrapure water and ethanol in sequence, and dried in vacuum to finally obtain the defective covalent triazine framework carrier material powder;

[0052] 4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com