Magnesium ferrite-based low-loss magnetic dielectric material and preparation method thereof

A magnesium ferrite, low-loss technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of affecting antenna performance, high material loss, unfavorable antenna transmission efficiency, etc., to improve radiation efficiency and bandwidth, Reduced loss, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

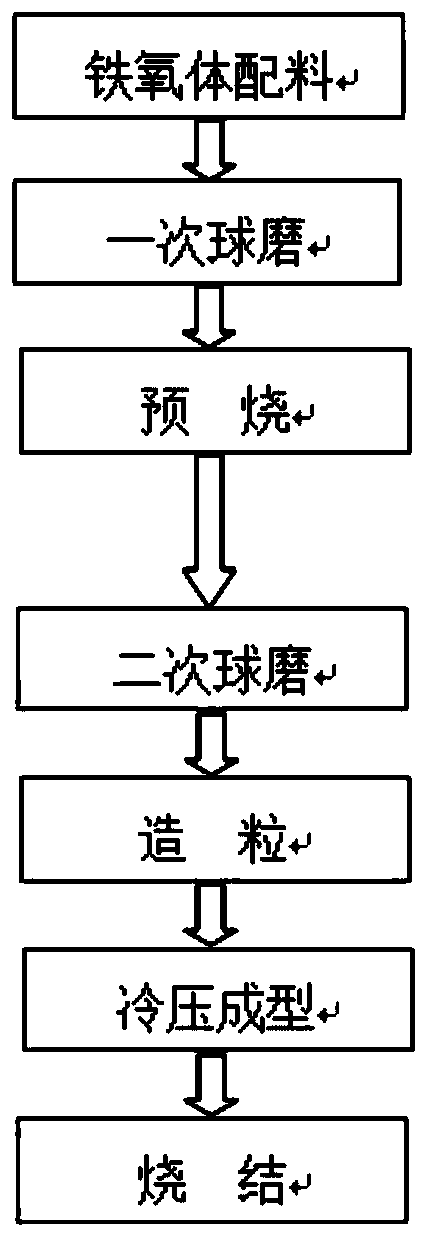

[0023] A method for preparing a magnesium ferrite-based magnetic dielectric material, comprising the following steps:

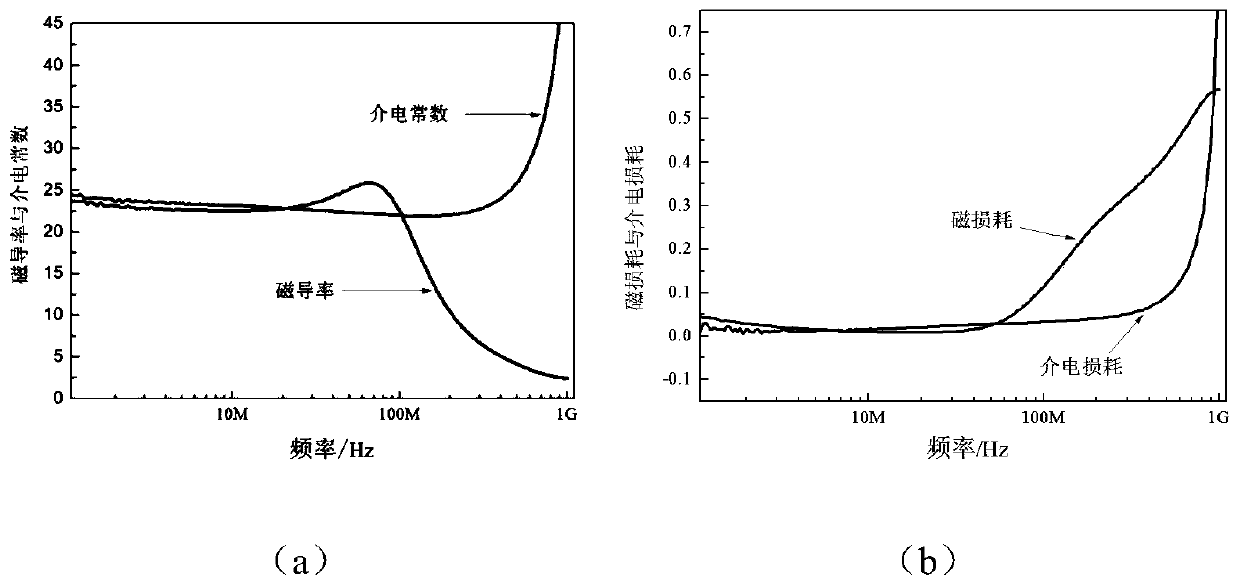

[0024] Step 1: Magnesium oxide (MgO), cadmium oxide (CdO), praseodymium oxide (Pr 2 o 3 ) and ferric oxide (Fe 2 o 3 ) as the raw material, according to the material Mg 0.8 Cd 0.2 Fe 1.96 PR 0.04 o 4 The ratio of the metal elements in the converted mass of MgO is 3.2g, the mass of CdO is 2.57g, and the mass of Pr 2 o 3 The mass of 0.66g, Fe 2 o 3 The quality of the product is 15.65g, and it is dried after weighing, mixing, and ball milling for 16 hours;

[0025] Step 2: Sieve the primary ball-milled dry material obtained in step 1 and put it into a sintering furnace for pre-sintering at a temperature of 1000°C for 3 hours, then cool to room temperature with the furnace to obtain a pre-sintered material;

[0026] Step 3: The calcined material obtained in step 2 is subjected to secondary ball milling for 16 hours, and the average particle size of th...

Embodiment 2

[0030] A method for preparing a magnesium ferrite-based magnetic dielectric material, comprising the following steps:

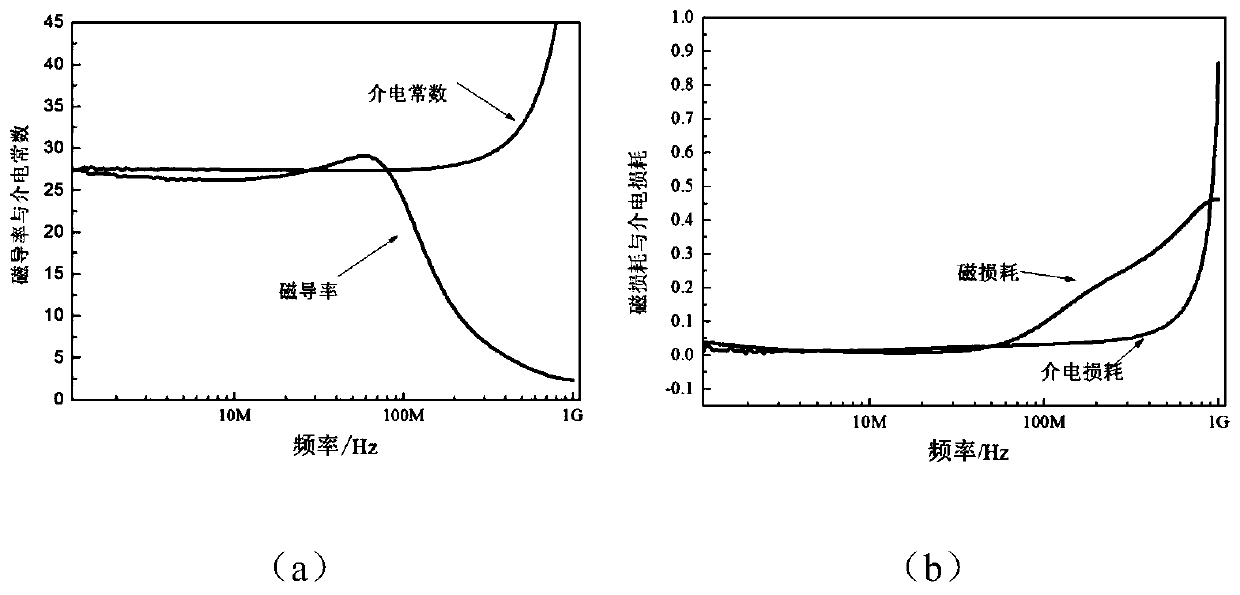

[0031] Step 1: Magnesium oxide (MgO), cadmium oxide (CdO), praseodymium oxide (Pr 2 o 3 ) and ferric oxide (Fe 2 o 3 ) as the raw material, according to the material Mg 0.8 Cd 0.2 Fe 1.94 PR 0.06 o 4 The ratio of the metal elements in the converted mass of MgO is 3.2g, the mass of CdO is 2.57g, and the mass of Pr 2 o 3 The mass of 0.99g, Fe 2 o 3 The quality of the product is 15.49g, and it is dried after weighing, mixing, and ball milling for 16 hours;

[0032] Step 2: Sieve the primary ball-milled dry material obtained in step 1 and put it into a sintering furnace for pre-sintering at a temperature of 1000°C for 3 hours, then cool to room temperature with the furnace to obtain a pre-sintered material;

[0033] Step 3: The calcined material obtained in step 2 is subjected to secondary ball milling for 16 hours, and the average particle size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com