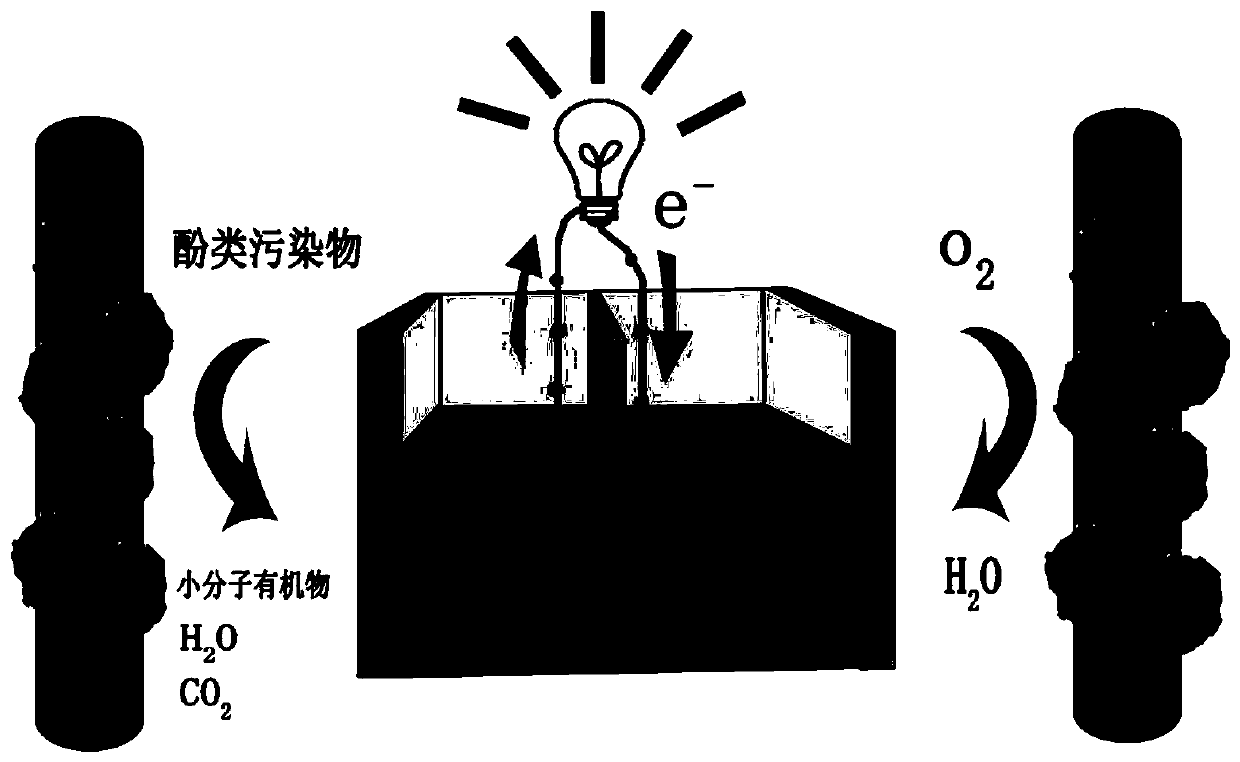

Phenolic sewage power generation device based on single-enzyme inorganic composite nanoflowers and preparation method and application thereof

An inorganic composite and power generation device technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of low output current of enzyme fuel cells, poor sewage treatment effect, short battery life, etc. problem, to achieve the effect of good electron transport, good water solubility and strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The construction of Yin and Yang poles in the power generation device:

[0035] (1) Preparation of AuNPs / Chit-RGO: prepare 5 mL of 0.5% w.t. chitosan solution (dissolved in 1% acetic acid solution), ultrasonically dissolve chitosan for 30 min, and slowly add 5 mL of 0.5 mg chitosan under stirring / mL graphene oxide (GO) solution and 23.6mg ascorbic acid (L-ascorbic acid). Put the mixture at 60°C for 6 hours to obtain a black suspension of Chit-RGO; filter it with a cellulose membrane with a diameter of 0.05 μm, wash it repeatedly with deionized water, and resuspend the precipitate in 10 mL of water for later use. Take 10mL Chit-RGO solution and 10mL AuNPs (maximum absorption peak wavelength: 498nm) solution in a centrifuge tube, sonicate for 1h, take the supernatant and centrifuge at 10,000rpm for 15min, and the precipitate is the AuNPs / Chit-RGO nanocomposite slurry.

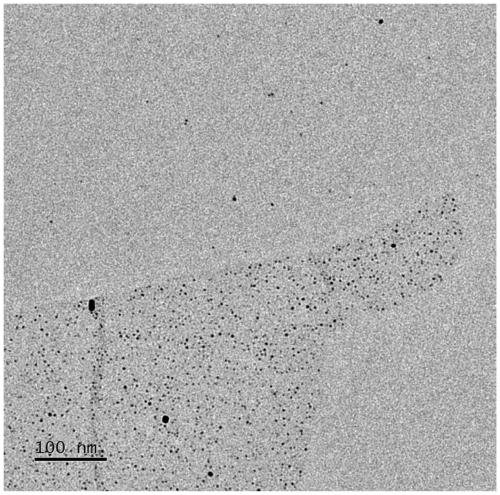

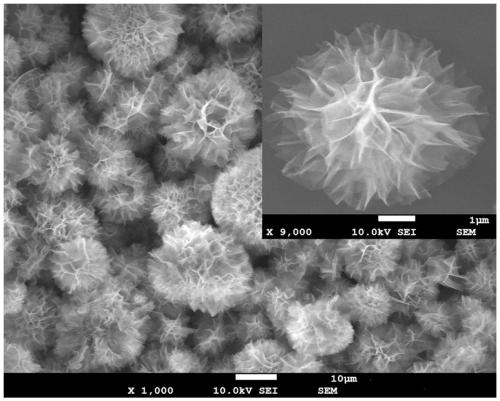

[0036] Such as figure 2 As shown, the AuNPs / Chit-RGO composite nanomaterial is characterized by ...

Embodiment 2

[0045] Cyclic Voltammetry Behavior Determination:

[0046] The electrochemical properties of the electrodes of the power generation device were characterized and determined using a CHI660c electrochemical workstation. The graphite felt was layered and drip-coated with AuNPs / Chit-RGO and Lac nanoflower, the graphite felt was drip-coated with AuNPs / Chit-RGO / Lac nanoflower homogenate as the working electrode, the Ag / AgCl electrode was used as the reference electrode, and the Pt electrode was used as the counter electrode. 50 mM citric acid / Na at pH=5 2 HPO 4 The cyclic voltammetry behavior of the electrode is measured by cyclic voltammetry curve (CV) in the buffer solution, and the implementation results are as follows Figure 5 As shown, in the figure 1 is the cyclic voltammetry behavior of graphite felt layered drop-coated AuNPs / Chit-RGO and Lac nanoflower, and 2 is the cyclic voltammetry behavior of graphite felt drop-coated AuNPs / Chit-RGO / Lac nanoflower homogenate, which ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com