Colored photosensitive resin composition, color filter and image display device

A technology of photosensitive resin and composition, which is applied in the direction of instruments, optics, and optomechanical equipment, etc. It can solve problems such as difficulty in forming target height difference, poor surface, and insufficient surface, and achieve minimum surface roughness, physical properties and performance. The effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0142] Synthesis example: Synthesis of alkali-soluble resin (B)

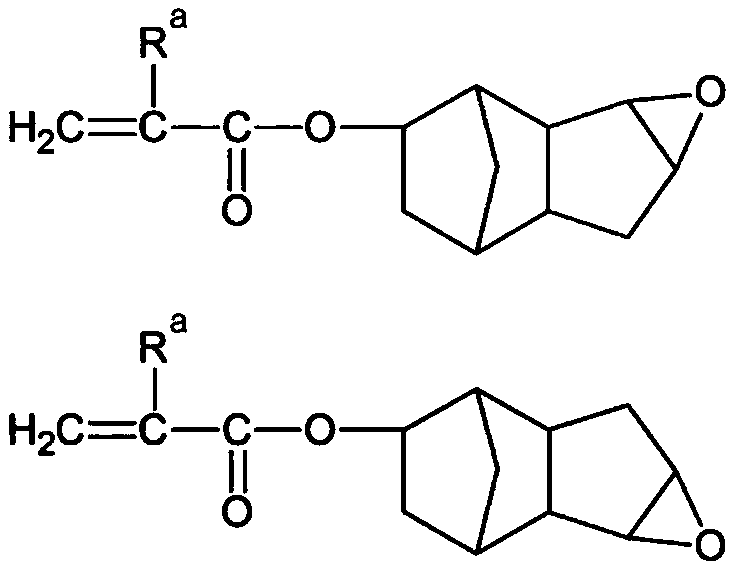

[0143] Put 277 g of methoxybutyl acetate into a separate flask with an inner volume of 1 L equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen gas introduction tube, and after raising the temperature to 80° C., dropwise add The 3,4-epoxytricyclo[5.2.1.0 2,6 ]decane-9-ylacrylate and 3,4-epoxytricyclo[5.2.1.0 2,6 ] a mixture of decane-8-yl acrylate [50:50 (molar ratio)] [the compound represented by the above chemical formula 1, R a =H] 301g, 49g of methacrylic acid and 23g of azobisdimethylvaleronitrile dissolved in 350g of methoxybutyl acetate were mixed solution, and matured for 3 hours to obtain a copolymer solution [solid content ( NV) 35.0% by weight]. The acid value (dry) of the obtained copolymer was 69.8 mgKOH / g, the weight average molecular weight (Mw) was 9,500, and the degree of dispersion Mw / Mn was 1.9.

[0144][chemical formula 1]

[0145]

Embodiment and

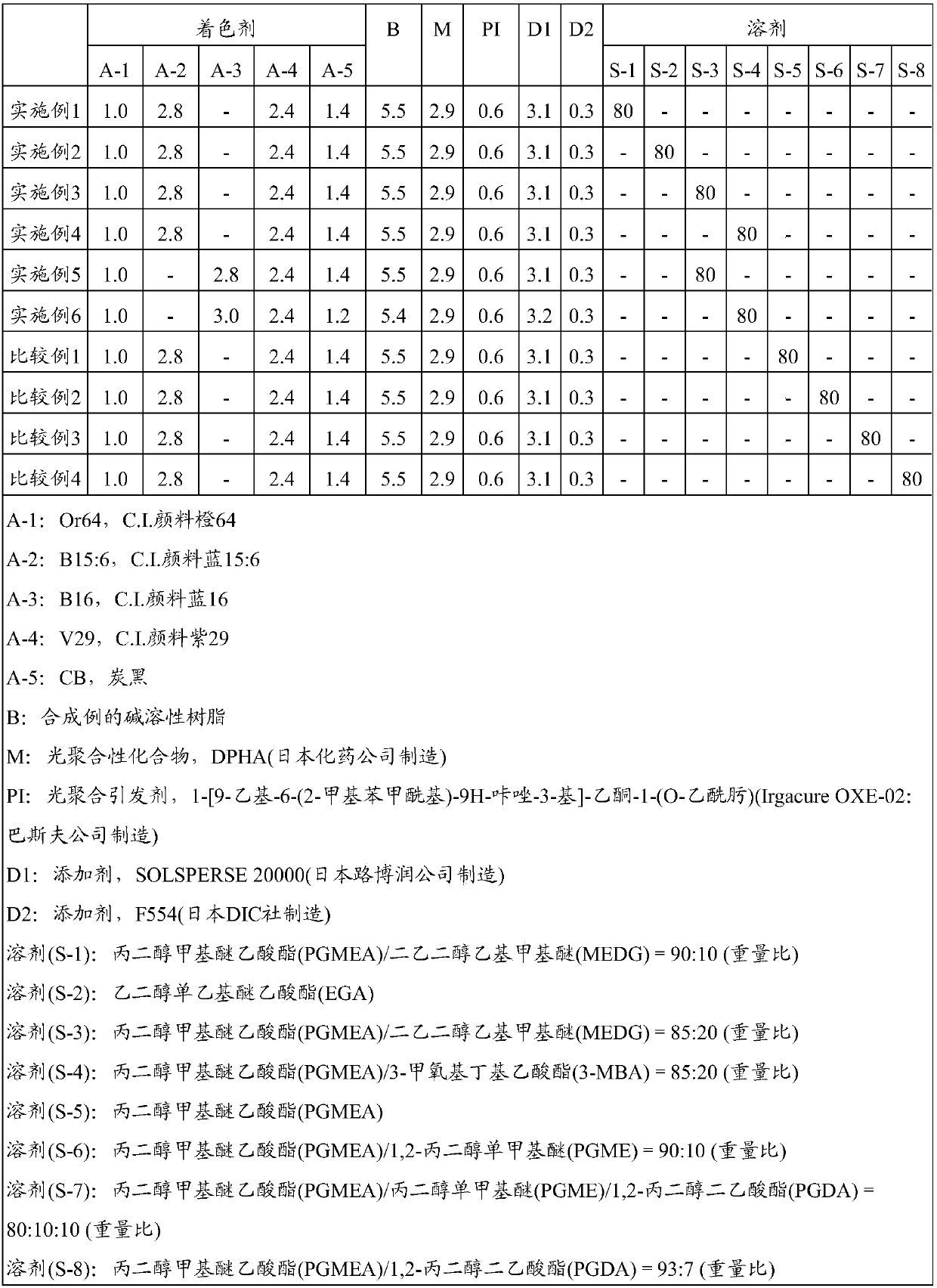

[0146] Examples and Comparative Examples: Production of Colored Photosensitive Resin Compositions

[0147] The colored photosensitive resin composition was manufactured according to the composition of following Table 1. At this time, the physicochemical properties of the solvent are shown in Table 2 below.

[0148] [Table 1]

[0149]

[0150] [Table 2]

[0151] No. type Viscosity (mPa·s) Vapor pressure (mmHg) |Δ(viscosity-vapor pressure)| 1 Propylene Glycol Methyl Ether Acetate (PGMEA) 1.3 2.8 1.5 2 Ethylene glycol monoethyl ether acetate (EGA) 1.3 1.2 0.1 3 3-Methoxybutyl acetate (3-MBA) 0.7 1.1 0.4 4 Diethylene glycol ethyl methyl ether (MEDG) 1.2 0.7 0.5 5 1,2-Propanediol diacetate (PGDA) 2.9 0.2 2.6 6 Propylene Glycol Monomethyl Ether (PGME) 1.9 8.7 6.8

experiment example

[0153] (1) Preparation of colored substrate

[0154] A 5 cm x 5 cm glass substrate (manufactured by Corning Incorporated) was washed with a neutral detergent and water, and then dried. The colored photosensitive resin compositions produced in Examples and Comparative Examples were spin-coated on the above-mentioned glass substrates so that the final film thickness was 3.0 μm, pre-baked at 100° C., and dried for 90 seconds to remove the solvent. Then, at 35mJ / cm 2 The exposure amount was exposed to form a pattern, and the non-exposed part was removed using an aqueous alkali solution. Next, post-firing was performed at 230° C. for 30 minutes to manufacture a colored substrate.

[0155] (2) Determination of viscosity

[0156] The viscosity of the solvent, the colored photosensitive resin composition of the Example, and the comparative example was measured at 20 degreeC using the Brookfield Viscometer DV-I+ (Brookfield Viscometer DV-I+, Brookfield company make).

[0157] (3) D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com