Composite modification method for surface protection of neodymium iron boron magnet

A compound modification and surface modification technology, which is applied in the fields of permanent magnet manufacturing, inductor/transformer/magnet manufacturing, ion implantation plating, etc., can solve the problems of insufficient improvement of the surface corrosion resistance of NdFeB magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

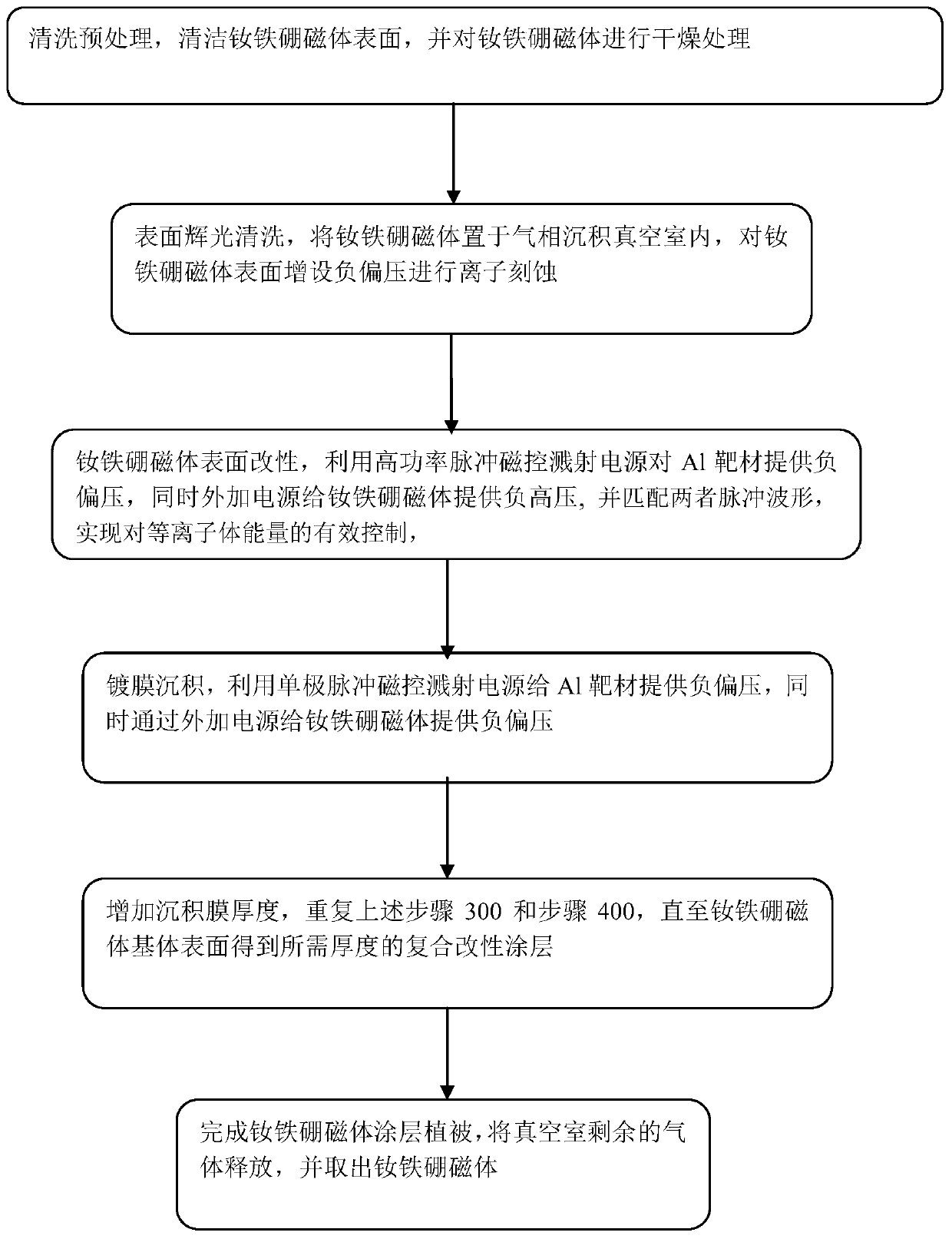

[0045] Such as figure 1 As shown, the present invention provides a composite modification method for surface protection of NdFeB magnets. The method includes three technologies: conventional magnetron sputtering, high-power pulse magnetron sputtering and plasma immersion ion implantation deposition. Among them, the conventional magnetron sputtering technology is used to ensure the overall deposition rate of the coating; the high-power pulse magnetron sputtering technology is used to generate high-density Al plasma, and at the same time, the substrate is loaded with pulsed high voltage to realize the plasma immersion of Al ions Inject the deposition process.

[0046] Including the following steps:

[0047] Step 100, cleaning pretreatment, cleaning the surface of the NdFeB magnet, and drying the NdFeB magnet.

[0048] Pretreatment includes surface oxide layer treatment, degreasing treatment, derusting treatment and dirt treatment of the magnet. Firstly, the NdFeB magnet is mec...

Embodiment 2

[0076] The present invention will be described in further detail below in conjunction with the accompanying drawings and actual cases. Taking the deposition of Al coating on the surface of NdFeB magnets as an example, select NdFeB magnets with a size of 25mm*25mm*12mm, and the specific steps are as follows:

[0077] Step 1: Pre-treatment of NdFeB magnet coating: Mechanically polish the NdFeB magnet, place it in acetone and alcohol for ultrasonic cleaning, and then use an air pump to dry the magnet surface.

[0078] Step 2: Place the NdFeB magnet on the workpiece rack in the vacuum chamber, and use a mechanical pump and a molecular pump to evacuate the chamber so that the chamber reaches a high vacuum level, and the vacuum degree is less than or equal to 10-3Pa.

[0079] Step 3: The argon gas flowing into the vacuum chamber is controlled by a mass flow meter, and the gas in the vacuum chamber is 1.5 Pa.

[0080] Step 4: Provide a negative pulse voltage to the workpiece holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com