Hollow fiber net-shaped perovskite catalyst, and preparation method and applications thereof

A fibrous mesh and catalyst technology, which is applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of particle pore size and PM contact, toxicity, etc. Active, easy-to-use effect of spinning technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

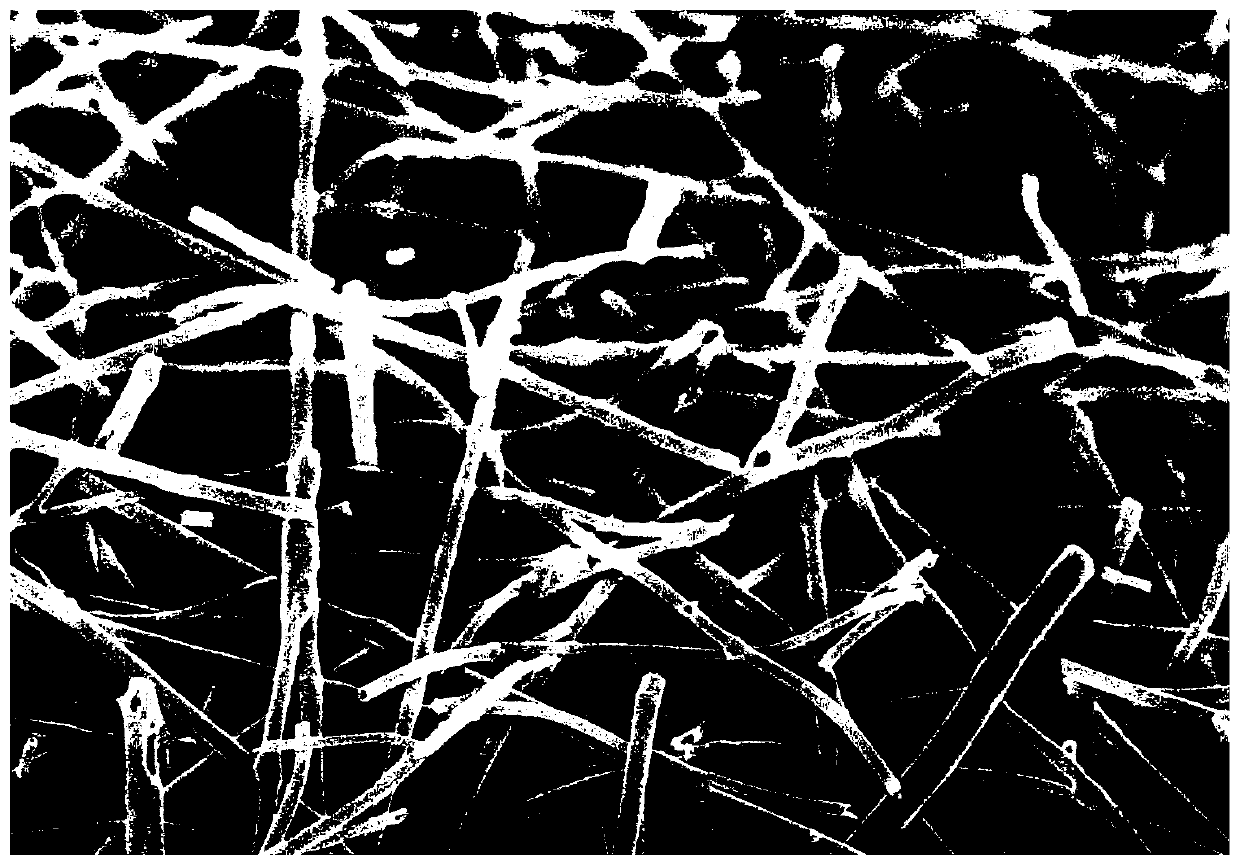

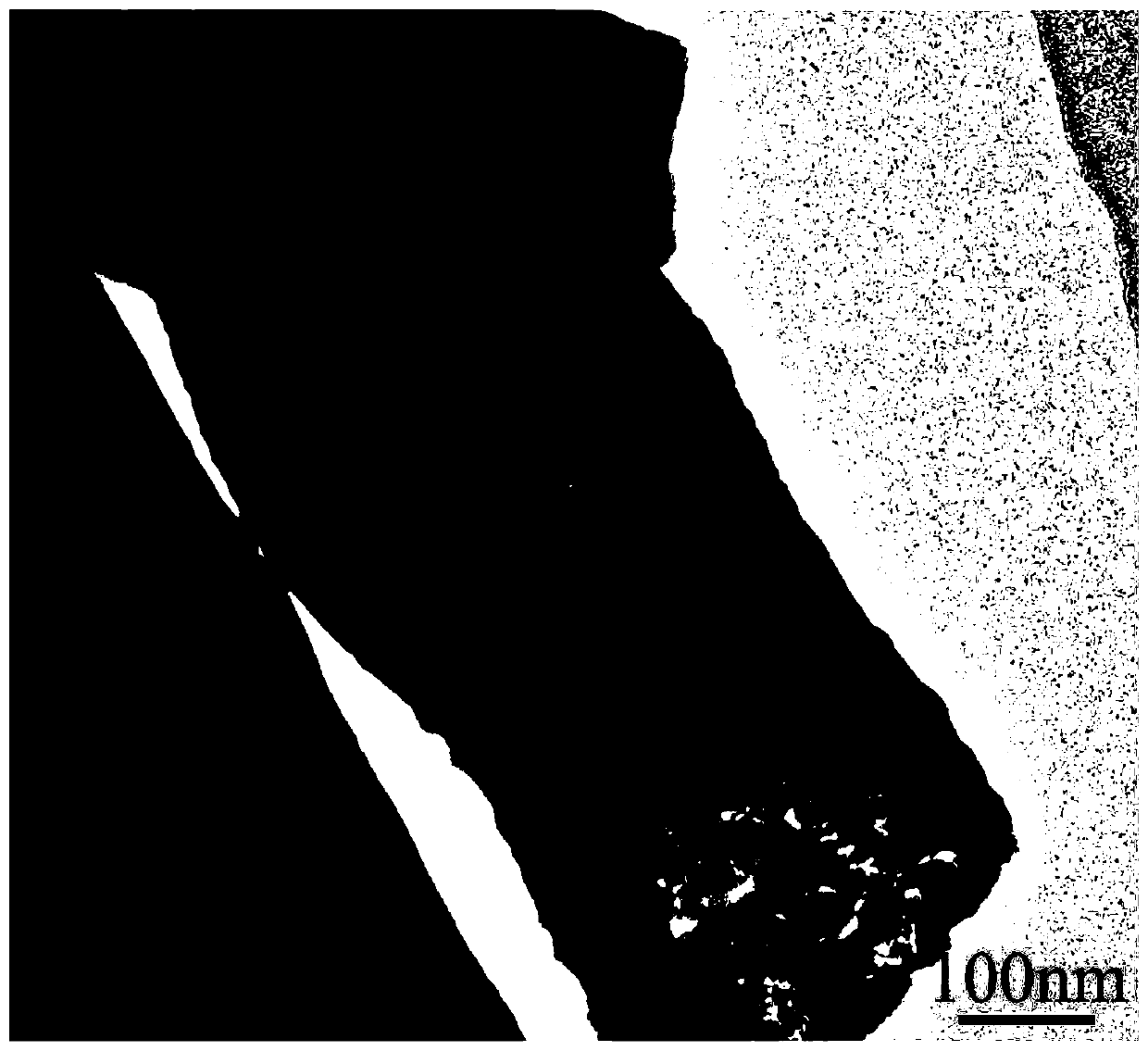

[0031] The present embodiment provides a kind of hollow fiber mesh perovskite catalyst is La 0.9 Sr 0.1 MnO 3 , the preparation method of described catalyst comprises the following steps:

[0032] (1) Measure 10 mL of deionized water and 5 mL of absolute ethanol in a beaker, and stir for 10 min to obtain an aqueous ethanol solution. Weigh 2.456g of anhydrous lanthanum nitrate, 0.178g of strontium nitrate, and 3.008g of manganese nitrate solution with a mass fraction of 50% and dissolve them in an aqueous ethanol solution, stir and dissolve at room temperature to obtain a metal salt solution with a metal ion concentration of 1.12mol / L. Weigh 3.528g of citric acid monohydrate into the metal salt solution, the molar ratio of metal ions and citric acid in the metal salt solution is 1:1, and continue to stir until the metal salt solution is clear to obtain a mixed solution. Then 11.5g of PVP (K90) was weighed and poured into a beaker containing the mixed solution, the mass ratio...

Embodiment 2

[0039] The present embodiment provides a kind of hollow fiber mesh perovskite catalyst is La 0.9 Sr 0.1 MnO 3 , the preparation method of described catalyst comprises the following steps:

[0040] Measure 10 mL of deionized water and 5 mL of absolute ethanol in a beaker, and stir for 10 min to obtain an aqueous ethanol solution. Weigh 2.456g of anhydrous lanthanum nitrate, 0.178g of strontium nitrate, and 3.008g of manganese nitrate solution with a mass fraction of 50% and dissolve them in aqueous ethanol solution, stir and dissolve at room temperature to obtain a metal salt solution with a metal ion concentration of 1.12mol / L. Weigh 3.528g of citric acid monohydrate into the metal salt solution, the molar ratio of metal ions and citric acid in the metal salt solution is 1:1, and continue to stir until the metal salt solution is clear to obtain a mixed solution. Then 1.16g of PVP (K90) was weighed and poured into a beaker containing the mixed solution, the mass ratio of the...

Embodiment 3

[0045] The present embodiment provides a kind of hollow fiber mesh perovskite catalyst is La 0.9 Sr 0.1 MnO 3 , the preparation method of described catalyst comprises the following steps:

[0046] Measure 10 mL of deionized water and 5 mL of absolute ethanol in a beaker, and stir for 10 min to obtain an aqueous ethanol solution. Weigh 2.456g of anhydrous lanthanum nitrate, 0.178g of strontium nitrate, and 3.008g of manganese nitrate solution with a mass fraction of 50% and dissolve them in aqueous ethanol solution, stir and dissolve at room temperature to obtain a metal salt solution with a metal ion concentration of 1.12mol / L. Weigh 3.528g of citric acid monohydrate into the metal salt solution, the molar ratio of metal ions and citric acid in the metal salt solution is 1:1, and continue to stir until the metal salt solution is clear to obtain a mixed solution. Then 0.46g of PVP (K90) was weighed and poured into the beaker containing the mixed solution, the mass ratio of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com