Iron-molybdenum composite metal oxide catalyst and preparation method and application thereof

A composite metal and oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, carbon compound catalysts, physical/chemical process catalysts, etc., can solve potential safety hazards in mixing, increase difficulty, and low propylene selectivity and other problems, to achieve the effect of low price, simple operation, high activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

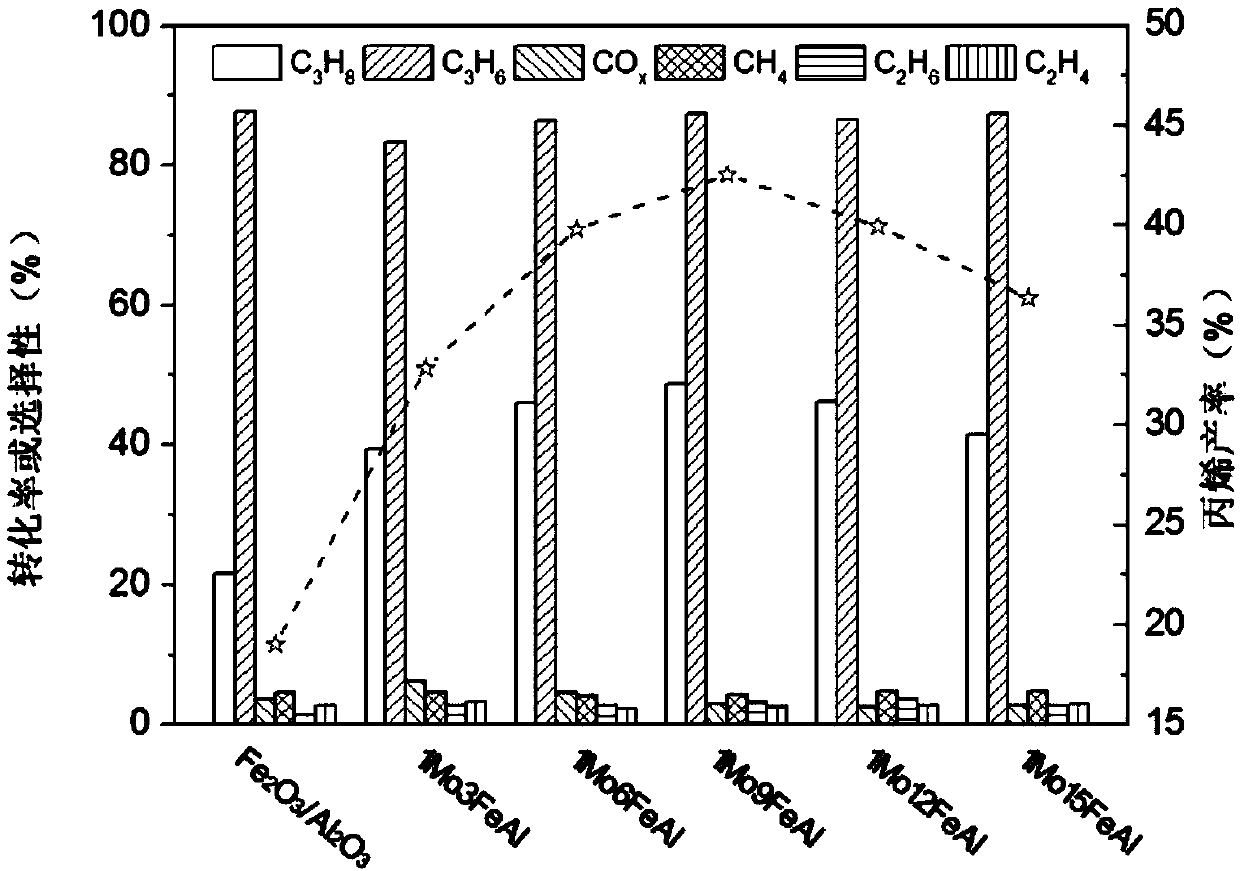

[0047] Step 1, according to the mol ratio of iron and molybdenum, in 2ml deionized water, add the ammonium molybdate of certain quality ((NH 4 ) 6 Mo 7 o 24 .4H 2 O), after dissolving completely, add 3.4g ferric nitrate nonahydrate (Fe(NO 3 ) 3 .9H 2 O), form a uniform mixed solution, the Al of 1.0g 2 o 3 Dip into the above solution.

[0048] Step 2, place the slurry obtained in step 1 at room temperature for 12 hours, then dry at 80°C for 12 hours, grind the obtained blocky solid, and bake it in air at 600°C for 6 hours to obtain the supported iron The molybdenum composite metal oxide catalyst has a molecular formula of 1MoxFeAl, where x=3, 6, 9, 12, 15, representing the molar ratio of iron and molybdenum.

[0049] In step 3, the 1MoxFeAl solid powder is pressed into tablets and sieved to obtain catalyst particles of 20-40 mesh.

Embodiment 2

[0051] Step 1, get 3.4g ferric nitrate nonahydrate (Fe(NO 3 ) 3 .9H 2 O) Added to 2ml of deionized water, after obtaining a clear solution, added 1.0g of Al 2 o 3 Do the impregnation.

[0052] Step 2, after drying the product obtained in step 1 at room temperature and 80°C for 12 hours, grind it evenly, transfer it to 600°C and roast it for 6 hours to obtain Fe 2 o 3 / Al 2 o 3 catalyst.

[0053] In step 3, the obtained catalyst powder is pressed into tablets and sieved to obtain 20-40 mesh catalyst particles.

Embodiment 3

[0055] Step 1, takes by weighing 0.36g ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 ﹒ 4H 2 O) dissolved in 4ml deionized water, 2.0gAl 2 o 3 immersed in the solution

[0056] Step 2, the product obtained in step 1 was dried at room temperature and 80°C for 12 hours, and the obtained solid was ground into powder, and calcined at 600°C for 6 hours in an air atmosphere to obtain MoO 3 / Al 2 o 3 catalyst

[0057] Step 3, the obtained MoO 3 / Al 2 o 3 The catalyst is pressed into tablets and sieved to obtain 20-40 mesh catalyst particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com