Method for entraining extraction and supercritical separation purification of squalene from Amaranthus hypochondriacus seeds

A supercritical separation and squalene technology, applied in chemical instruments and methods, adsorption purification/separation, hydrocarbon purification/separation, etc., can solve the high cost of silver nitrate restricting industrial applications, squalene oxidation, separation difficulties, etc. problems, to achieve the effect of improving comprehensive utilization value, avoiding oxidation, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

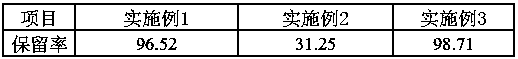

Embodiment 1

[0021] Extract grain amaranth seed oil: weigh 100g grain amaranth seed, crush it to 1mm, and dry it at the same time to obtain grain amaranth seed powder for later use; then squeeze it with a rotary oil press to obtain the first oil phase and oil cake; mix the oil cake with 50ml petroleum Mix ether, heat and reflux at 85°C for 2 hours, filter to obtain the filtrate and filter residue, distill the filtrate under reduced pressure to remove petroleum ether, and recycle the petroleum ether to obtain the second oil phase; combine the first oil phase and the second oil phase, and uniformly Stir to obtain virgin amaranth seed oil for subsequent use;

[0022] Steam distillation deodorization: put the amaranth seed oil obtained in the previous step in the steam distillation deodorization device, start the vacuum pump, and when the absolute pressure of the whole system is below 100Pa, turn on the heater and slowly heat the oil to 180°C , then open the cock of the direct steam conduit, a...

Embodiment 2

[0029] Extracting grain amaranth seed oil: Weigh 100g grain amaranth seed, crush to 1.5mm, and dry at the same time to obtain grain amaranth seed powder for later use; then press with a rotary oil press to obtain the first oil phase and oil cake; mix the oil cake with 50ml Mix petroleum ether, heat and reflux at 85°C for 2 hours, filter to obtain filtrate and filter residue, distill the filtrate under reduced pressure to remove petroleum ether, and recycle the petroleum ether to obtain the second oil phase; combine the first oil phase and the second oil phase, Stir evenly to obtain virgin amaranth seed oil for subsequent use;

[0030] Steam distillation deodorization: put the amaranth seed oil obtained in the previous step in the steam distillation deodorization device, start the vacuum pump, and when the absolute pressure of the whole system is below 100Pa, turn on the heater and slowly heat the oil to 180°C , then open the cock of the direct steam conduit, and let in the dir...

Embodiment 3

[0037] Extract grain amaranth seed oil: weigh 100g grain amaranth seed, crush it to 1mm, and dry it at the same time to obtain grain amaranth seed powder for later use; then squeeze it with a rotary oil press to obtain the first oil phase and oil cake; mix the oil cake with 80ml petroleum Mix ether, heat and reflux at 85°C for 2 hours, filter to obtain the filtrate and filter residue, distill the filtrate under reduced pressure to remove petroleum ether, and recycle the petroleum ether to obtain the second oil phase; combine the first oil phase and the second oil phase, and uniformly Stir to obtain virgin amaranth seed oil for subsequent use;

[0038] Steam distillation deodorization: put the amaranth seed oil obtained in the previous step in the steam distillation deodorization device, start the vacuum pump, and when the absolute pressure of the whole system is below 100Pa, turn on the heater and slowly heat the oil to 180°C , then open the cock of the direct steam conduit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com