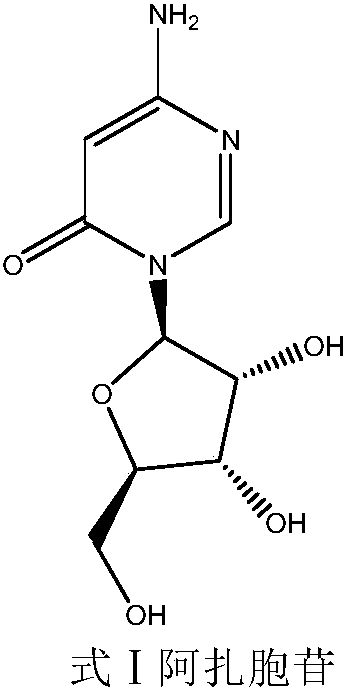

Preparation method of azacitidine

A technology for azacitidine and azacytosine, which is applied in the field of preparation of azacitidine, can solve the problems of increased risk, complicated process, long time consumption, etc., and achieves improved purity and yield, mild reaction conditions, and improved reaction efficiency. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

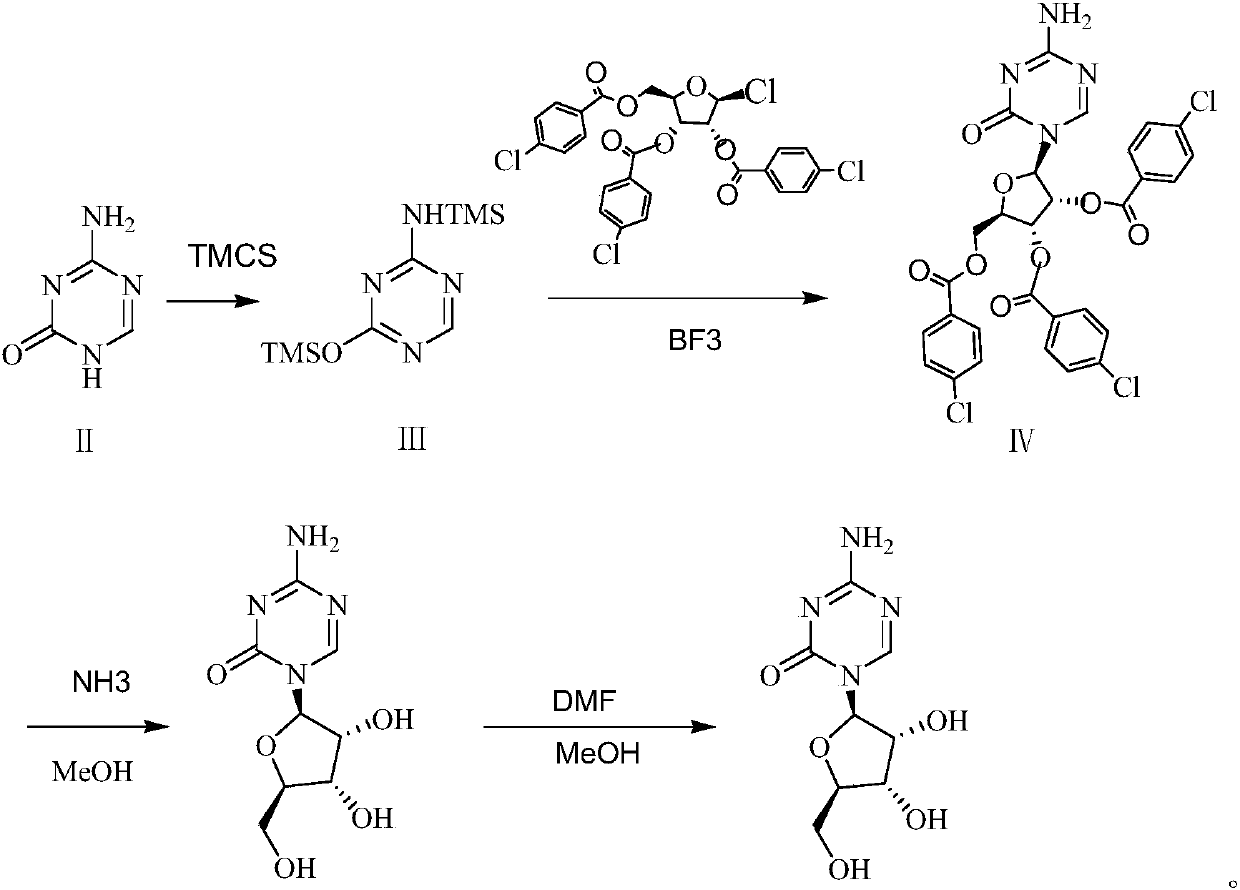

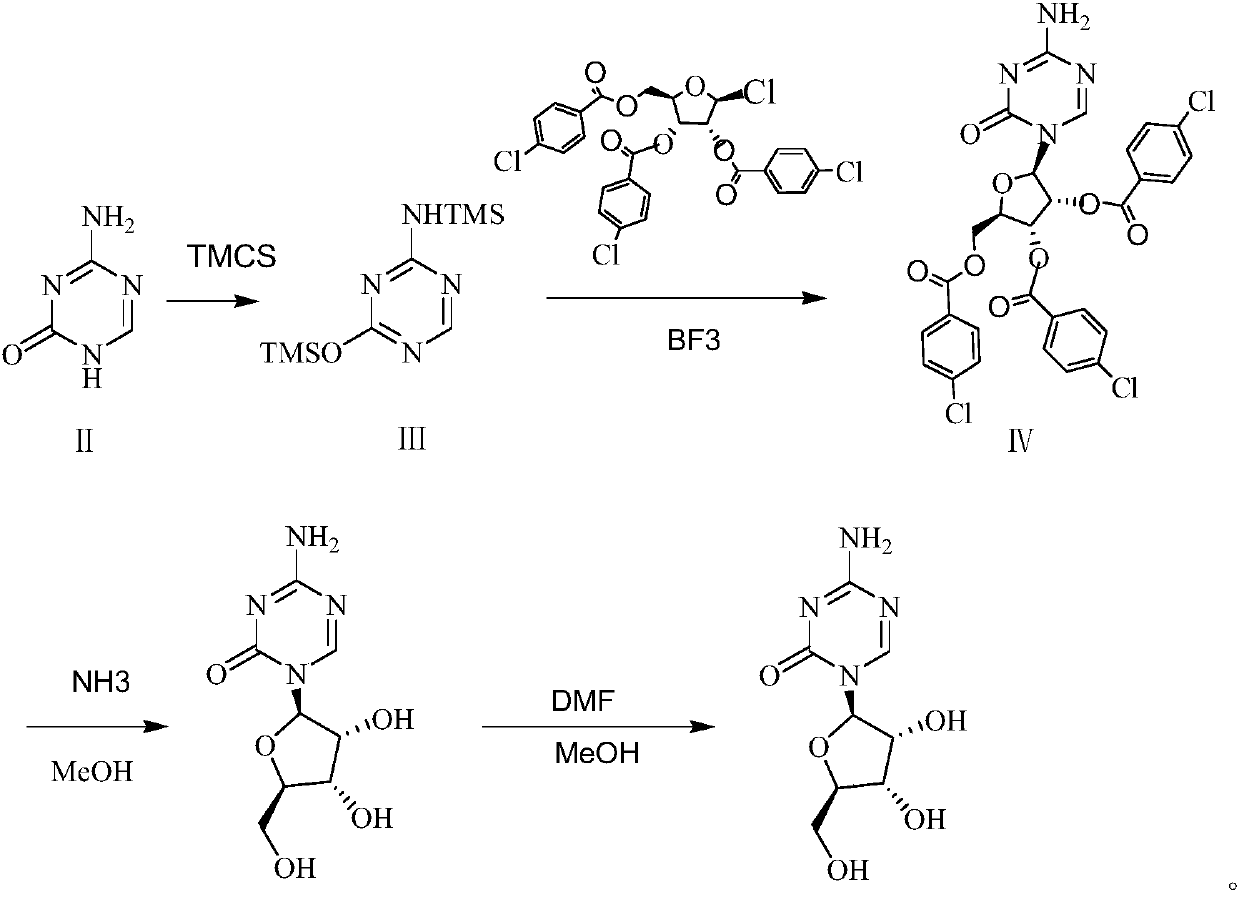

Method used

Image

Examples

Embodiment 1

[0025] Put 33.6g of 5-azacytosine into a three-necked flask, add 134.4ml of trimethylchlorosilane and 0.85g of ammonium sulfate, raise the temperature to 70°C, the solution is clear for about 2 hours, and then distill off the solvent under reduced pressure to constant weight to obtain A Zacitidine intermediate Ⅰ.

[0026] Dissolve 76.8g (0.3mol) of azacitidine intermediate I in 614.4ml of dichloromethane, put it into a three-neck flask and stir, then add 0.27mol of 1-chloro-2,3,5-tri-O-p-chlorobenzyl For acyl-β-D-ribose, slowly add 0.33mol boron trifluoride dropwise, control the temperature at -5°C and stir the reaction. After reacting for 2 hours, add saturated saline, separate the liquids to obtain an organic phase, and then add saturated bicarbonate to the organic phase Sodium solution was separated to obtain an organic phase, which was dried with anhydrous sodium sulfate for 2 hours, filtered to obtain an organic phase, and distilled under reduced pressure to constant weig...

Embodiment 2

[0029] Put 33.6g of 5-azacytosine into a three-necked flask, add 336ml of trimethylchlorosilane and 0.85g of ammonium sulfate, heat up to 80°C, and the solution is clear for about 2 hours, then distill off the solvent under reduced pressure to constant weight to obtain A Zacitidine intermediate Ⅰ.

[0030] Dissolve 76.8g (0.3mol) of azacitidine intermediate I in 1536ml of dichloromethane, put it into a three-neck flask and stir, then add 0.39mol of 1-chloro-2,3,5-tri-O-p-chlorobenzoyl -β-D-ribose, slowly add 0.45mol boron trifluoride dropwise, control the temperature at 15°C and stir the reaction, after reacting for 2 hours, add saturated saline, separate the liquids to obtain an organic phase, then add saturated sodium bicarbonate solution to the organic phase , separated to obtain an organic phase, dried over anhydrous sodium sulfate for 2 hours, filtered to obtain an organic phase, and distilled under reduced pressure to constant weight to obtain azacitidine intermediate II...

Embodiment 3

[0033] Put 33.6g of 5-azacytosine into a three-necked flask, add 168ml of trimethylchlorosilane and 0.85g of ammonium sulfate, raise the temperature to 80°C, the solution is clear for about 2 hours, and then evaporate the solvent under reduced pressure to constant weight to obtain Aza Cytidine intermediate I.

[0034] Dissolve 76.8g (0.3mol) of azacitidine intermediate I in 691.2ml of dichloromethane, put it into a three-necked flask and stir, then add 0.285mol of 1-chloro-2,3,5-tri-O-p-chlorobenzyl For acyl-β-D-ribose, slowly add 0.36mol boron trifluoride dropwise, control the temperature at 5°C and stir the reaction. After reacting for 2 hours, add saturated saline, separate the liquids to obtain an organic phase, and then add saturated sodium bicarbonate to the organic phase The solution was separated to obtain an organic phase. After drying with anhydrous sodium sulfate for 2 hours, the organic phase was obtained by suction filtration, and distilled under reduced pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com