Method for preparing amino acid-and-polypeptide-modified AIE polymer nanoparticles

A nanoparticle, polypeptide modification technology, applied in chemical instruments and methods, instruments, analytical materials, etc., can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

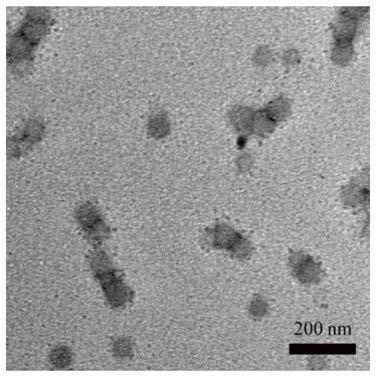

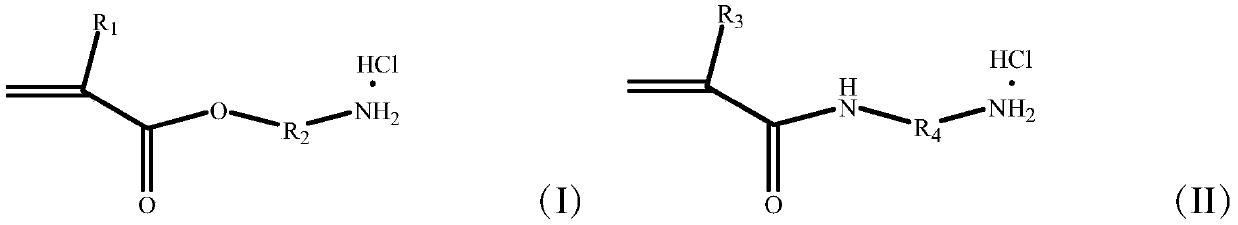

[0077] Weigh 0.2g of O-50 emulsifier and 0.1g of 2-aminoethyl methacrylate hydrochloride, and dissolve them in 12.5g of deionized water to obtain an aqueous phase solution.

[0078] Weigh 0.01g of AIE-6 molecules and 0.02g of azobisisobutyronitrile and dissolve in a mixed solution of 0.06g of n-hexadecane and 0.9g of methyl methacrylate to obtain an oil phase solution; add the water phase solution to the oil phase The solution was pre-emulsified by stirring to obtain a coarse emulsion; the container containing the coarse emulsion was placed in an ice-water bath, and a stable monomer fine emulsion was obtained by ultrasonication with a power of 400W for 9 minutes; nitrogen and oxygen were removed, and the temperature Raise to 65°C, react for 6h under nitrogen protection, and prepare amino-modified AIE polymer nanoparticle emulsion. With a molecular weight cut-off of 5000g·mol –1 The dialysis bag was dialyzed for three days, and the water change frequency was changed every 2h o...

Embodiment 2

[0095] Weigh 0.5 g of Tween 20 and 0.15 g of 2-aminoethyl methacrylate hydrochloride, dissolve them in 15 g of deionized water, and obtain an aqueous phase solution.

[0096] Weigh 0.0075g of AIE-12 molecules and 0.015g of azobisisoheptanonitrile and dissolve in a mixed solution of 0.08g of n-hexadecane and 1.35g of styrene to obtain an oil phase solution; add the water phase solution to the oil phase solution In the process, the coarse emulsion was prepared after stirring and pre-emulsification; the container containing the coarse emulsion was placed in an ice-water bath, and a stable monomer fine emulsion was obtained by ultrasonic wave with a power of 200W for 20 minutes; nitrogen and oxygen were removed, and the temperature rose to 60° C., under the protection of nitrogen, and react for 12 hours to prepare an amino-modified AIE polymer nanoparticle emulsion. With a molecular weight cut-off of 5000g·mol –1 The dialysis bag was dialyzed for three days, and the water change ...

Embodiment 3

[0102] Weigh 0.3g of MOA-9 and 0.05g of 2-aminoethyl methacrylate hydrochloride, dissolve them in 15g of deionized water, and obtain an aqueous phase solution.

[0103] Weigh 0.05g of the AIE-15 molecule and 0.05g of azobisisobutyronitrile and dissolve in a mixed solution of 0.08g of n-hexadecane, 0.45g of styrene and 0.5g of methyl methacrylate to obtain an oil phase solution; The solution is added to the oil phase solution, and the coarse emulsion is obtained after stirring and pre-emulsification; the container containing the coarse emulsion is placed in an ice-water bath, and the ultrasonic wave with a power of 600W is used for 5 minutes to obtain a stable monomer fine emulsion; Nitrogen was used to remove oxygen, the temperature was raised to 60° C., and under the protection of nitrogen, the reaction was carried out for 24 hours to prepare an amino-modified AIE polymer nanoparticle emulsion. With a molecular weight cut-off of 5000g·mol –1 The dialysis bag was dialyzed for...

PUM

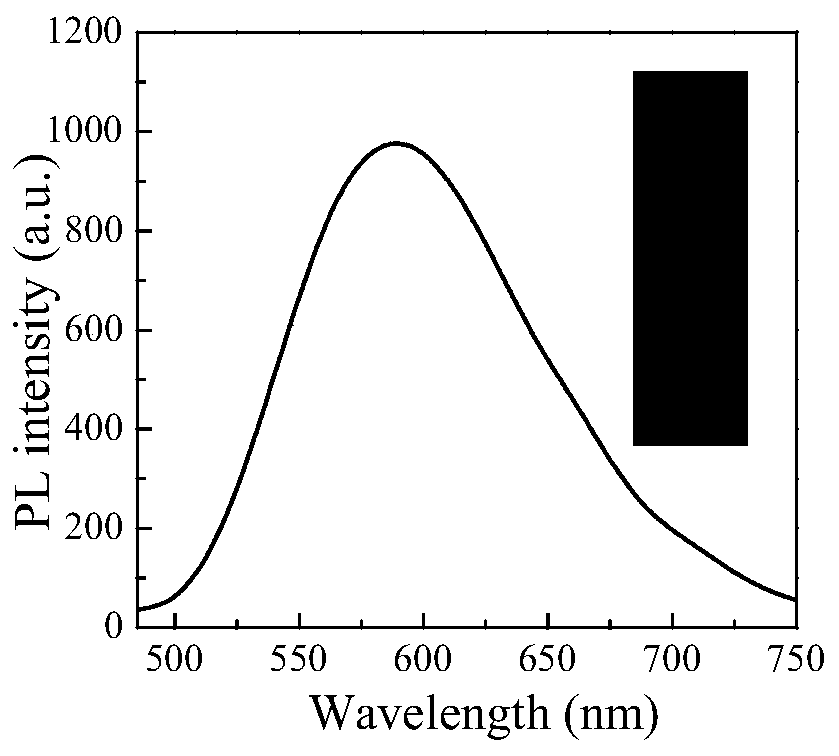

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com