Microbial inoculum for preparing caged chicken fermentation mattress material and preparation method of inoculum

A technology of composite microbial agent and microbial composition, which is applied in the field of microbial engineering, can solve the problems of chicken manure with little decomposition effect, no fermentation function, and no obvious heat production, so as to improve the humus rate of litter and improve the microbial efficiency. Diversity, ammonia gas reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Separation of Bacillus megaterium and Lactobacillus plantarum

[0037] Isolation of Bacillus megaterium: Take 10g of decomposed chicken manure and connect it to 200mL enriched medium (2g ammonium sulfate, 2.17g sodium succinate, 0.25g potassium dihydrogen phosphate, 0.125g magnesium sulfate, 0.125g NaC1, 1000mL water) In, every 3 days, transfer to a new enrichment medium with an inoculum of 3%, continue enrichment culture for 30 days, dilute and spread on an ammonium sulfate plate, select fast-growing large colonies, and repeat separation and purification twice . The obtained strains were inoculated into the enriched medium for shaking culture, and at the same time, Gliss reagent and diphenylamine reagent were used to track and detect the production of nitrite and nitrate. 28 strains were obtained by preliminary screening, and then the strains were multiplexed into chicken manure In the extract (preparation of chicken manure extract: mix chicken manure and tap ...

Embodiment 2

[0039] Example 2 Preparation of composite microbial agent

[0040] The configuration of the compound microbial agent goes through the following three steps from the inclined surface bacteria to the amplification of the finished product.

[0041] 1. Primary expansion: After each purified and cultivated strains (Bacillus amyloliquefaciens, Bacillus megaterium, Trichoderma longiflorum, Lactobacillus plantarum) are taken out of the preserved slope, they are respectively inoculated into the four prepared seeds Culture medium separately. Each 1L bottle contains 200ml medium. Lactobacillus plantarum is cultured in a constant temperature incubator at 37°C for 48h. Bacillus amyloliquefaciens and Bacillus megaterium are cultured on a shaker at 35°C at 150r / min for 48h. , Trichoderma longibrachiatum was cultured with shaking at 30°C at 120r / min for 96h on a shaker.

[0042] In the first-level expansion culture, the slant medium and seed medium of various bacteria are well-known basic medium. ...

Embodiment 3

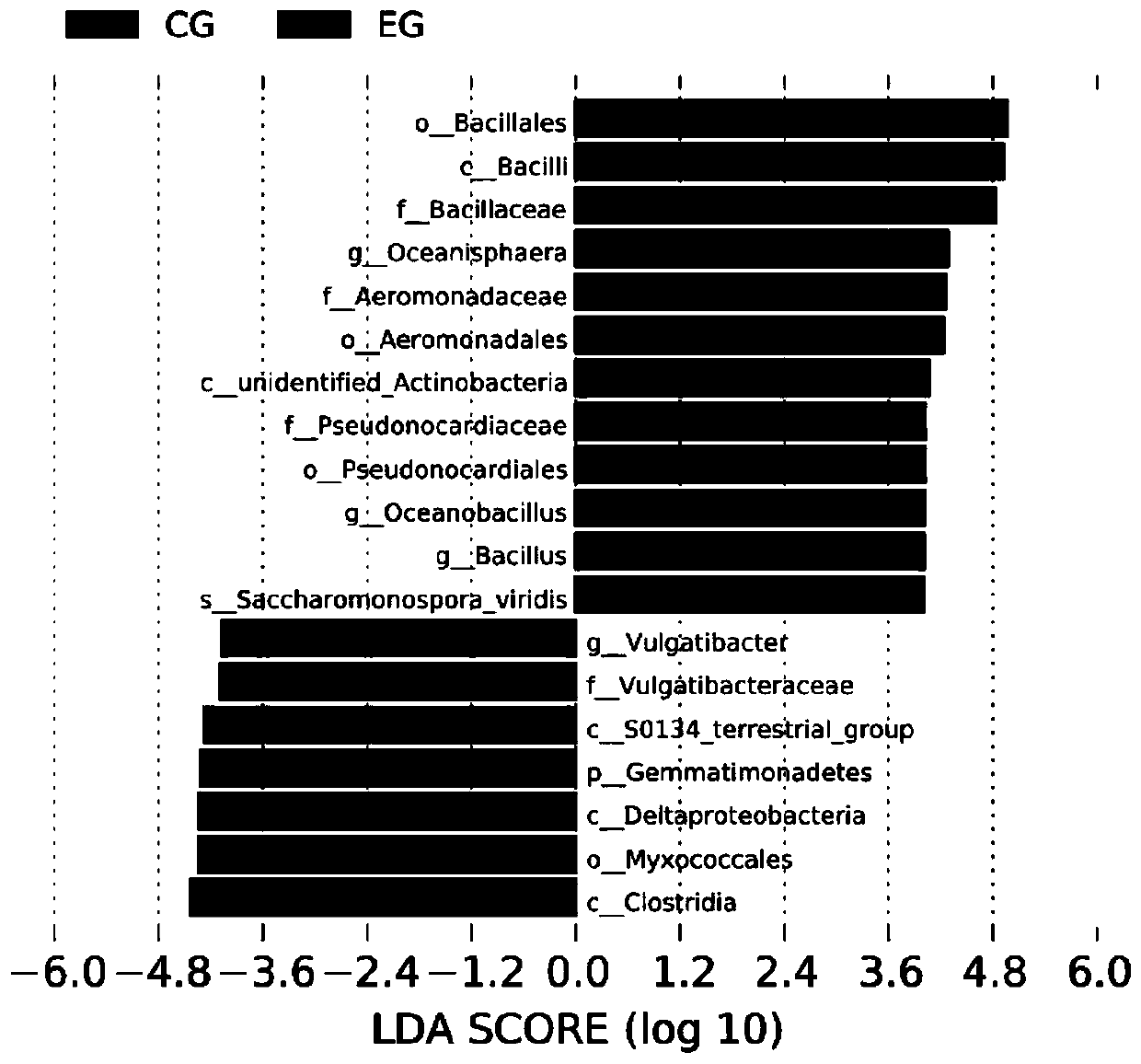

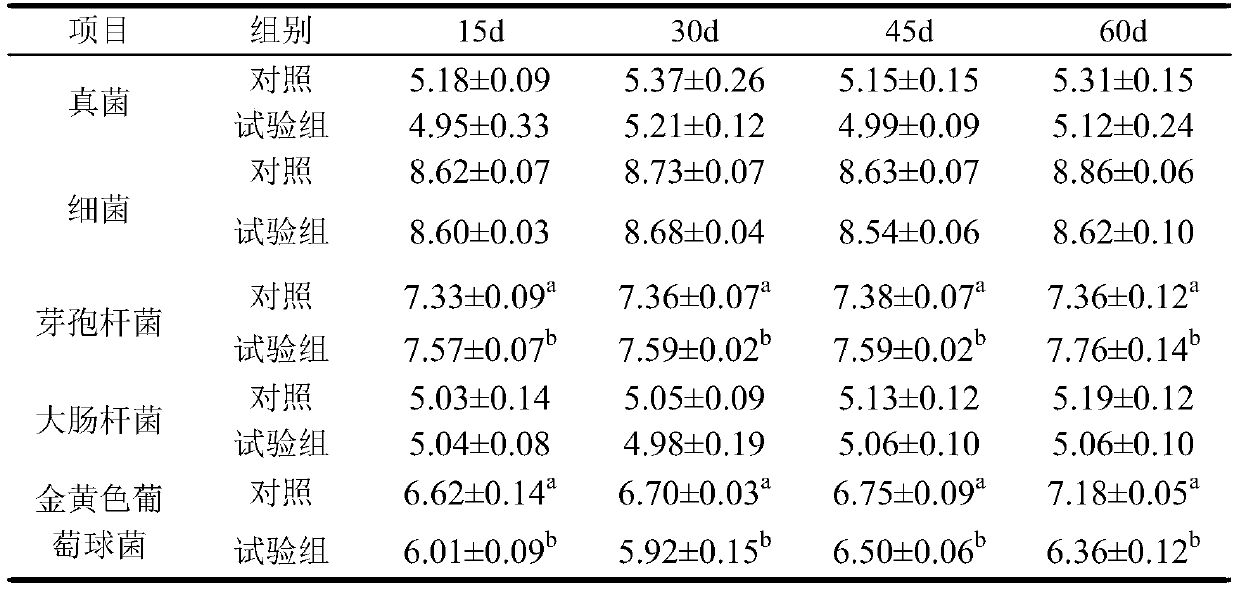

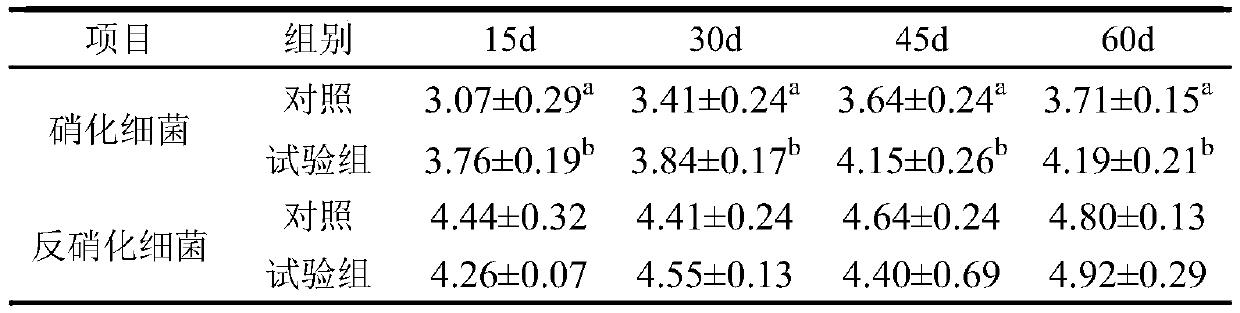

[0046] Example 3: The effect test of the compound microbial starter of the present invention on the caged chicken fermentation bed

[0047] From October 2017 to December 2017, an application experiment of the product of the present invention on the bed surface substrate was carried out in a chicken farm. The fermentation bed of caged chicken is about 40cm with fungus chaff, and the surface is about 10cm of sawdust / rice husk. The weight ratio of sawdust to rice husk is 1:1. Run and stir with a rake machine to mix the litter. The thickness of the litter is 50cm. The test group uses 50 grams of fermentation bed bacteria per square meter of fermentation bed. The method of sprinkling is to mix the fermentation bed bacteria and bran evenly, then sprinkle them on the surface of the fermentation bed, and run and stir with the rake machine; The weight ratio of bran is: 50g of fermentation bed inoculum and 1kg of bran. The control group only sprinkled 1kg of bran per square meter.

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com