A polysilazane coating material, preparation method and application method

A polysilazane, coating material technology, applied in the coating, the device for coating liquid on the surface, the pretreatment surface, etc., can solve the problems of uneven film density and etching degree, etc., to prevent uneven film thickness , the effect of fast conversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

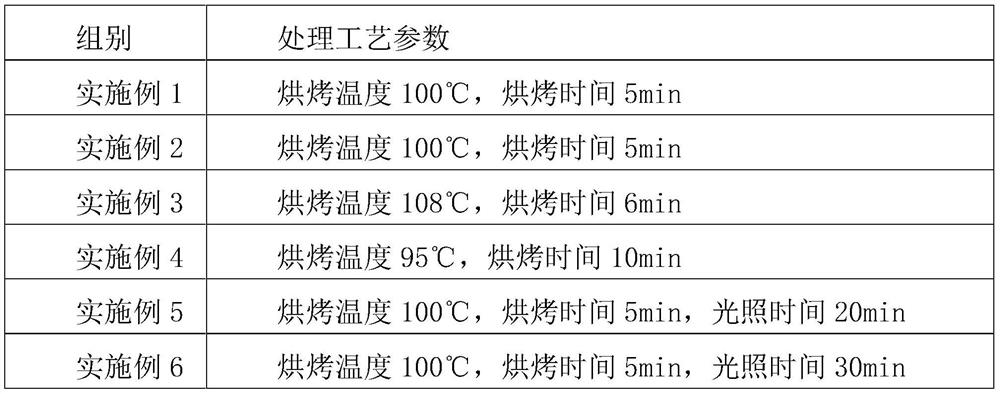

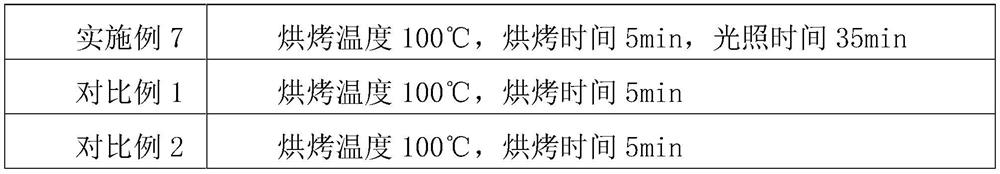

Examples

preparation example Construction

[0015] In the embodiment of the present invention, a method for preparing a polysilazane coating material is provided, which specifically includes:

[0016] Polysilazane solutions are obtained by known synthetic methods;

[0017] Diluting the polysilazane solution and adding an initiator to obtain a mixed solution;

[0018] The mixed solution was filtered through a filter to obtain a coating material.

[0019] The predetermined synthetic method for obtaining the polysilazane solution specifically includes:

[0020] Add dichlorosilane to pyridine and react at minus 10-2°C to form a white solid complex (SiH 2 Cl 2 -2C 5 h 5 N), continue to feed ammonia gas to react, control the introduction speed of ammonia gas in this process, to ensure that the temperature of the reaction system remains at about 0 ° C, carry out vacuum filtration after the end of the reaction, remove by-product ammonium chloride, and obtain poly Silazane pyridine solution;

[0021] The polysilazane pyri...

preparation example 1

[0031] Introduce 1000ml of dry pyridine in a 2-liter four-port glass reactor with a gas conduit, a condenser, and a stirrer. Under -5°C ice-cooling, introduce 103 grams of dichlorosilane to form a white solid complex (SiH 2 Cl 2 -2C 5 h 5 N). The reaction compound is introduced into the ammonia gas through the drying tube to react while stirring while continuing to cool. Control the ammonia gas introduction rate to ensure that the reaction temperature will not rise too much. Generally kept at about 0 ℃. A total of 103 grams of ammonia were introduced. After the reaction is completed, vacuum filtration is performed to remove the by-product ammonium chloride to obtain a polysilazane pyridine solution. Distilling the pyridine solution under reduced pressure and adding xylene to obtain a xylene solution of polysilazane. On the basis of the xylene solution, a butyl ether solvent is added for solvent replacement to obtain a polysilazane solution.

preparation example 2

[0033] Add the polysilazane pyridine solution obtained in Preparation Example 1 to a mixed solution of pyridine and xylene to obtain a solution with a solid content of 20%. Under a dry nitrogen stream, stir and heat at 110° C. for 10 hours, then distill under reduced pressure and solvent Replacement to obtain a high-component polysilazane solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com