Preparation method and application of vanadium selenide-nitrogen/sulfur co-doped carbon compound potassium ion battery negative electrode material with high performance

A carbon composite, battery negative electrode technology, applied in the direction of active material electrode, battery electrode, secondary battery manufacturing, etc., can solve the problems of low conductivity and large volume change, improve potassium storage performance, wide source, improve electronic The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) First wash the waste cow hair with deionized water, and then wash it at 65 o Dry under the temperature of C, then it is crushed into ox hair powder; And the ox hair powder is placed in 60 o C water bath in zinc chloride aqueous solution for 12 hours, suction filtration, and then at 70 o Dry at C temperature; finally the powder is added to the container of the ionic liquid with the molar ratio of ethylene glycol and choline chloride being 1:0.5, in a microwave oven at 120 o Reaction at C for 1 hour, centrifuged and dried to obtain keratin-containing dry matter;

[0027] 2) Weigh a certain mass of keratin (200 mg) and vanadyl acetylacetonate (500 mg) into deionized water (40 mL), ultrasonicate for a certain period of time (10 minutes), then stir for 10 minutes, and finally o Dry in C drying oven, collect gray-green solid sample;

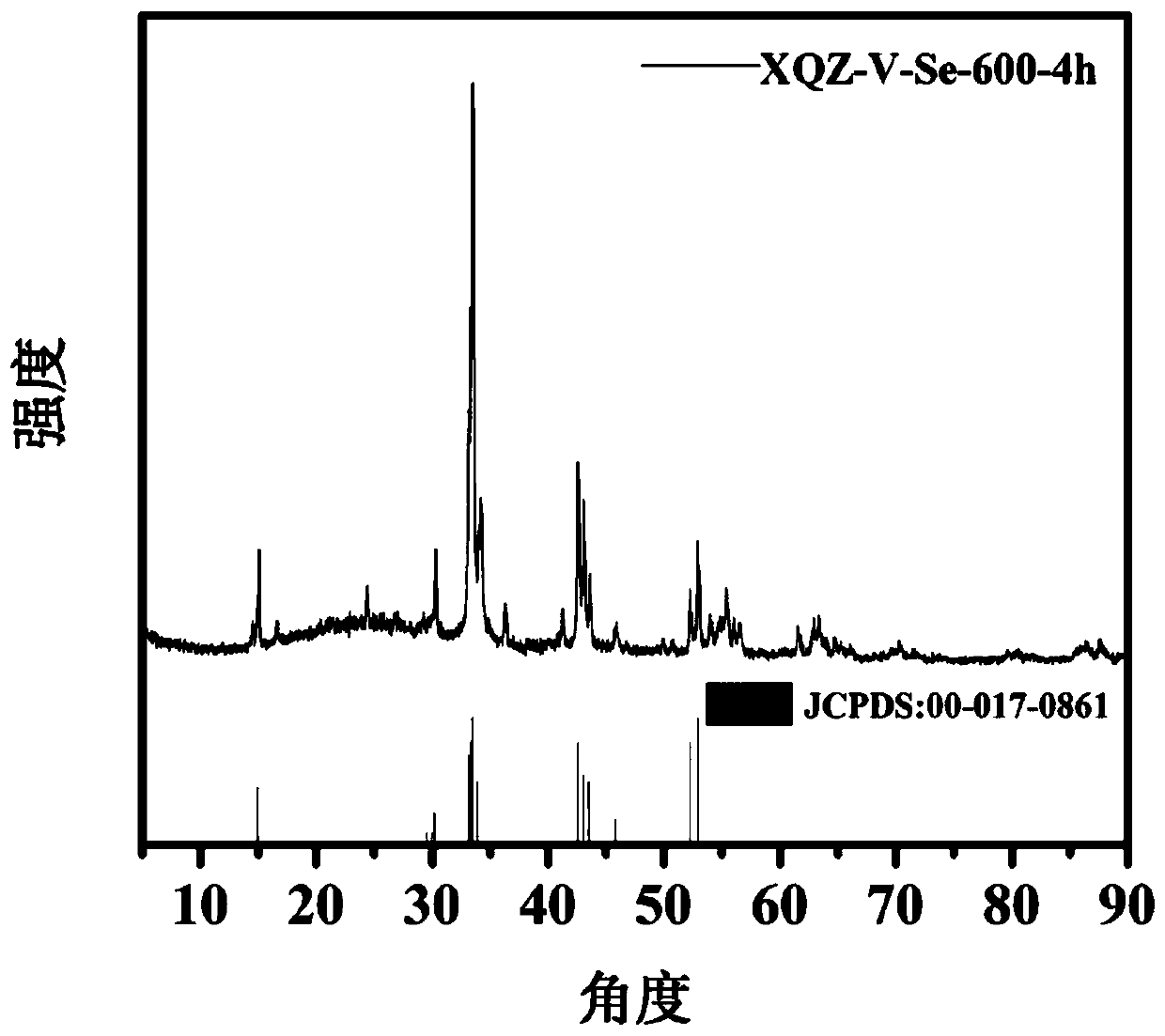

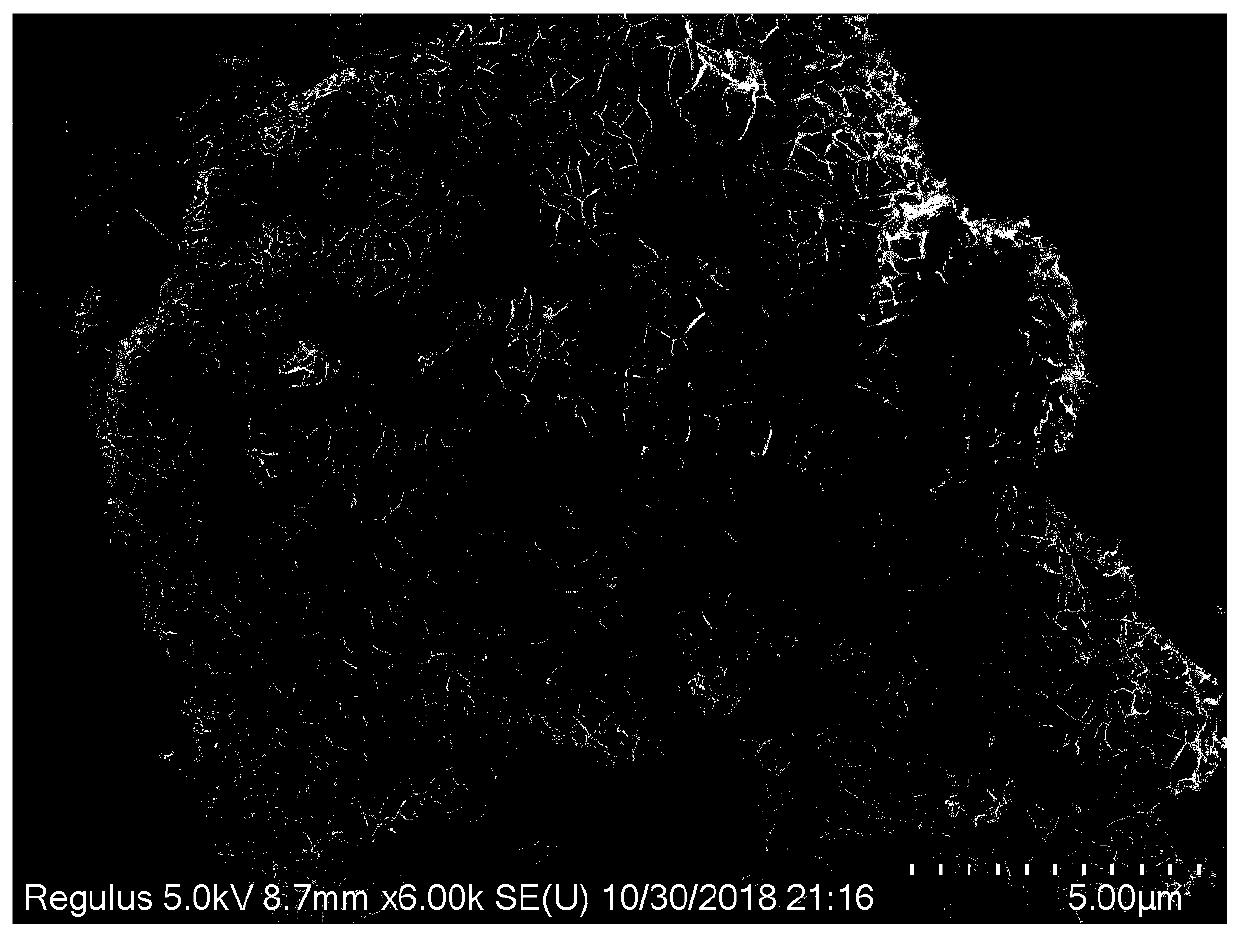

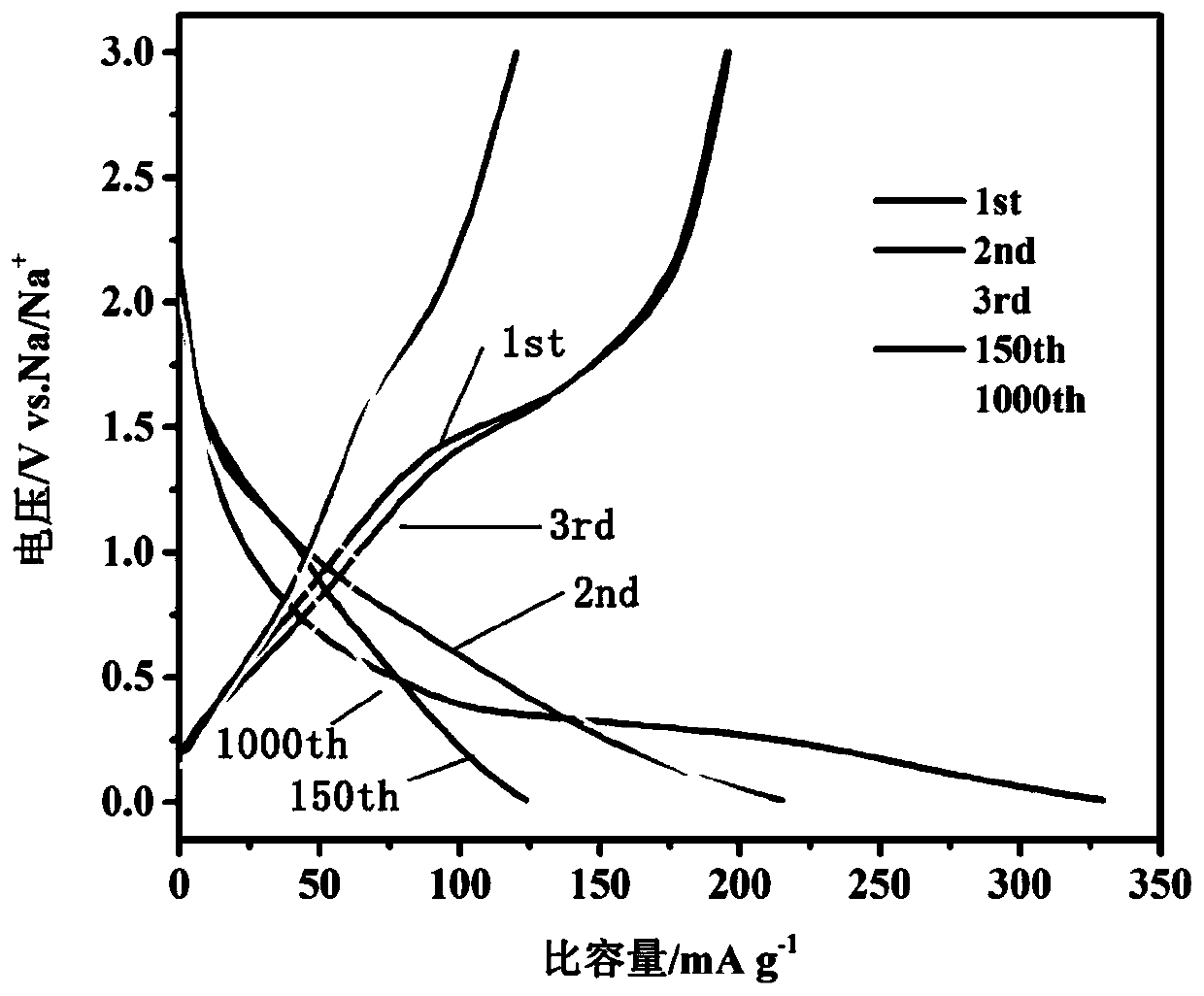

[0028] 3) Grind the gray-green solid obtained in step 2) into powder, then weigh the solid powder and selenium powder with a mass ratio o...

Embodiment 2

[0032] 1) First wash the waste cow hair with deionized water, and then wash it at 70 o Dry under the temperature of C, then it is crushed into ox hair powder; And the ox hair powder is placed in 70 o C water bath in zinc chloride aqueous solution for 12 hours, suction filtration, and then in 80 o Dry at C temperature; Finally, the powder is added to the container of the ionic liquid with a molar ratio of ethylene glycol and choline chloride of 1:0.3, in a microwave oven at 150 o C for 0.5 hours, centrifuged and dried to obtain dry matter containing keratin;

[0033] 2) Weigh a certain mass of keratin (0.5 g) and vanadyl sulfate (5 g) into deionized water (200 mL), first sonicate for a certain period of time (15 minutes), then stir for 10 minutes, and finally at 70 o Dry in C drying oven, collect gray-green solid sample;

[0034] 3) Grind the gray-green solid obtained in step 2) into powder, then weigh the solid powder and selenium powder with a mass ratio of 1:3 and put the...

Embodiment 3

[0037] 1) First wash the waste cow hair with deionized water, and then wash it at 65 o Dry at a temperature of C, then crush it into powder; and place the cow hair powder at 60 o C water bath in zinc chloride aqueous solution for 12 hours, suction filtration, and then at 70 o Dry at C temperature; Finally, the powder is added to the container of the ionic liquid that the molar ratio of ethylene glycol and choline chloride is 1:1, and is heated in a microwave oven at 80 o C for 2 hours, centrifuged and dried to obtain dry matter containing keratin;

[0038] 2) Weigh a certain mass of keratin (1.25 g) and vanadyl acetylacetonate (2.5 g) into deionized water (150 mL), first sonicate for a certain period of time (12 minutes), then stir for 10 minutes, and finally at 70 o Dry in C drying oven, collect gray-green solid sample;

[0039] 3) Grind the gray-green solid obtained in step 2) into powder, then weigh the solid powder and selenium powder with a mass ratio of 1:2 and put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com