Preparation technology for producing isomaltulose

A technology for the preparation of isomaltulose, which is applied in the field of preparation of isomaltulose, can solve the problems of low purity of isomaltulose, large labor consumption, complicated preparation process, etc., and shorten the production cycle and reduce production The effect of simple cycle and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

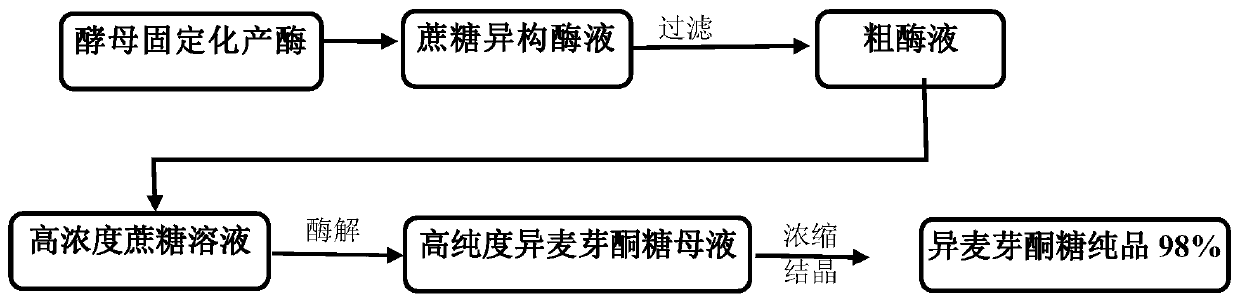

[0040] A kind of preparation technology of producing isomaltulose, described preparation technology comprises the following steps:

[0041] Step 1, prepare mother liquor;

[0042] Step 2, preparing immobilized enzyme-producing bacteria;

[0043] Step 3, prepare crude enzyme liquid;

[0044] Step 4, isomaltulose mother liquor;

[0045] Step 5, preparing a finished product of isomaltulose with a purity greater than 95%.

[0046] Further, the parts by weight of the main components required to prepare the mother liquor are as follows: 15-30 parts of polyvinyl alcohol, 5-10 parts of sodium alginate, 5-10 parts of sodium methylcellulose (CMC), epoxy poly 4-8 parts of amine.

[0047] Raw materials used in the present invention: all are commercially available products.

[0048] Wherein the enzyme production medium takes 3-5% bean cake powder, 1-2% beef extract, 10-15% sucrose, and 78-86% water by weight percentage, mixes evenly, and sterilizes at a temperature of 115°C 30min to ...

Embodiment 1

[0051] A preparation process for producing isomaltulose, comprising the following steps:

[0052] Step 1. In parts by weight, take 15 parts of polyvinyl alcohol, 5 parts of sodium alginate, 5 parts of sodium methylcellulose, and 4 parts of epoxy polyamine, mix them evenly, and sterilize for 30 minutes at a temperature of 115°C. Cool to a temperature of 30°C to obtain the mother liquor for subsequent use;

[0053] Step 2: Add an equal volume of Yarrowia lipolytica bacterium liquid to the mother liquor prepared in step 1, mix evenly to form a mixed solution, and soak the mixed solution in a 0.2% glutaraldehyde solution at a temperature of at 30-35°C for 2 hours, and perform the first curing to form a solidified mixed solution I, and then soak the solidified mixed solution I in a calcium chloride solution with a concentration of 1%. After 30 minutes, carry out the second curing to form the solidified mixed solution II, take it out, wash the solidified mixed solution II with dist...

Embodiment 2

[0059] A preparation process for producing isomaltulose, comprising the following steps:

[0060]Step 1. In parts by weight, take 20 parts of polyvinyl alcohol, 8 parts of sodium alginate, 8 parts of sodium methylcellulose, and 6 parts of epoxy polyamine, mix them evenly, and sterilize for 30 minutes at a temperature of 115°C. Cool to a temperature of 33°C to obtain the mother liquor for subsequent use;

[0061] Step 2. Add an equal volume of Yarrowia lipolytica bacterium liquid to the mother liquor prepared in step 1, mix well to form a mixed solution, and soak the mixed solution in a 0.4% glutaraldehyde solution at a temperature of at 30-35°C for 2.5 hours, for the first curing to form a solidified mixed solution I, and then soak the solidified mixed solution I in a calcium chloride solution with a concentration of 1.5%, at a temperature of 28-30°C, The time is 40 minutes, and the second curing is carried out to form the solidified mixed solution II, which is taken out, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com