Molybdenum sulfide/cesium lead halide perovskite quantum dot photoelectric detector and preparation method

A photodetector and molybdenum sulfide technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve the problems of high cost, small application range, and low performance, and achieve low cost, wide application range, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

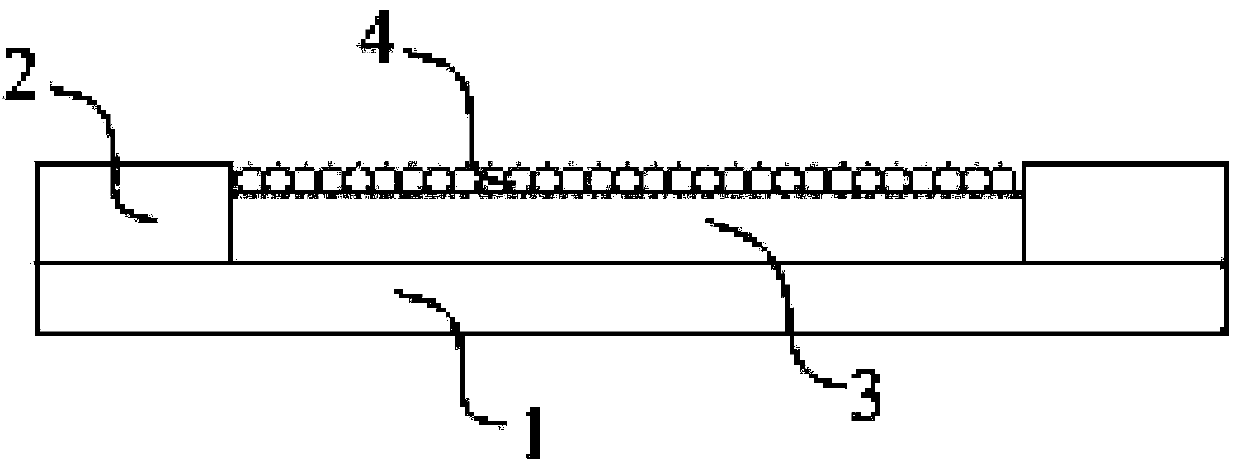

[0032] A preparation method of a two-dimensional molybdenum sulfide / cesium lead halide perovskite quantum dot composite nanostructure photodetector, comprising the following steps:

[0033] 1) take the substrate as the substrate layer, and make the surface electrodes separated from each other on the substrate layer;

[0034] 2) get the two-dimensional molybdenum sulfide thin film, and cover it on the substrate layer between the surface electrodes to obtain the two-dimensional molybdenum sulfide thin film layer;

[0035] 3) taking cesium lead-halogen quantum dots and uniformly covering them on the surface of the two-dimensional molybdenum sulfide thin film layer to obtain a cesium-lead-halogen quantum dot layer;

[0036] 4) get the ligand, add unsaturated fatty acid to get a mixed solution, the ratio of the ligand to the unsaturated fatty acid is 0.05-0.25mol / L; add a ligand solvent in the mixed solution to make a ligand solution, the mixed solution and The volume ratio of the...

Embodiment 1

[0044] A preparation method of a two-dimensional molybdenum sulfide / cesium lead halide perovskite quantum dot composite nanostructure photodetector, comprising the following steps:

[0045] 1) Take Si / SiO 2 The substrate, as the substrate layer, was fabricated on Si / SiO using photolithography 2 The desired electrode pattern is obtained on the substrate, and then the substrate is put into a vacuum coating system to perform vapor deposition of gold electrodes, and the thickness of the vapor deposition electrodes is 30 nm;

[0046] 2) Using polymethyl methacrylate as the carrier material, the two-dimensional molybdenum sulfide film is uniformly dispersed on the substrate between the two surface electrodes to obtain a two-dimensional molybdenum sulfide film layer;

[0047] 3) get the n-octane solution of cesium lead halogen quantum dots, the concentration is 50mg / mL, cover it evenly on the surface of the two-dimensional molybdenum sulfide thin film layer, carry out spin coating o...

Embodiment 2

[0053] A preparation method of a two-dimensional molybdenum sulfide / cesium lead halide perovskite quantum dot composite nanostructure photodetector, comprising the following steps:

[0054] 1) get mica sheet, as substrate layer, use photolithography to obtain required electrode pattern on this substrate, then this substrate is put into vacuum coating system to carry out vapor deposition silver electrode, and the thickness of vapor deposition electrode is 50nm;

[0055] 2) Using polymethyl methacrylate as the carrier material, spin coating a layer of polymethyl methacrylate on the molybdenum sulfide film by spin coating, and the spin coating speed is 2500 r / min. Baked for 10min; immersed in sodium hydroxide solution, heated for 30min; covered on the above-mentioned substrate layer, dried at 100°C, and cleaned to obtain a two-dimensional molybdenum sulfide thin film layer;

[0056] 3) Take the toluene solution of cesium lead halogen quantum dots with a concentration of 20 mg / mL,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com