High-flux and high-selectivity nanofiltration membrane and preparation method thereof

A high-selectivity, nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor stability and decreased membrane retention performance, and achieve the effect of high permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

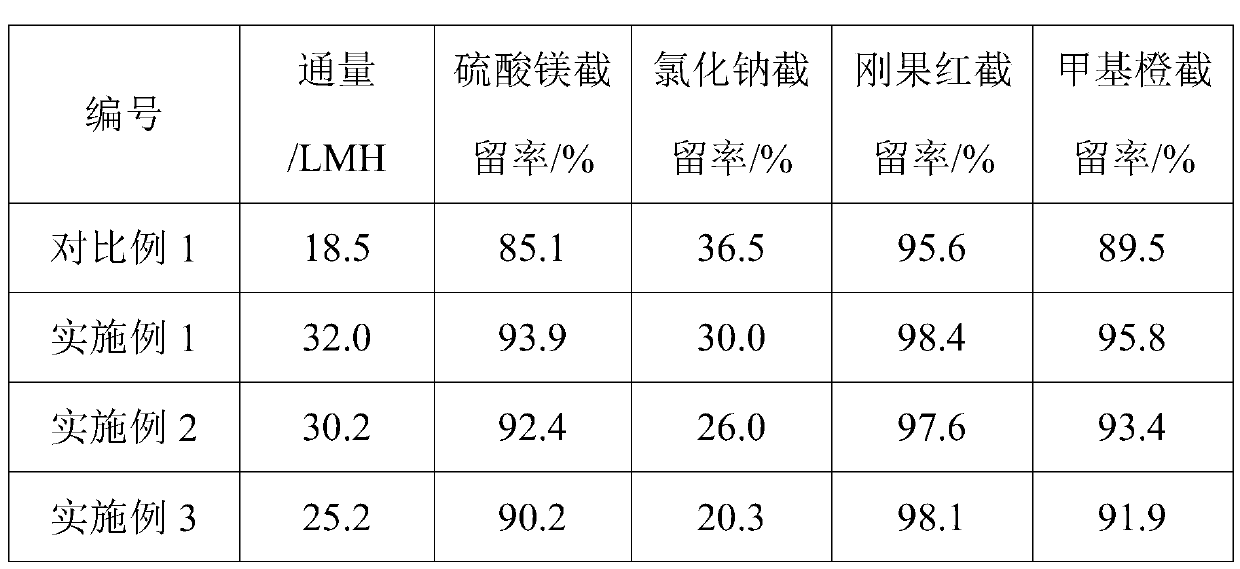

Examples

Embodiment 1

[0036] Preparation of aspartate-calcium metal (Asp-Ca) chelate:

[0037] Dissolve aspartic acid powder and anhydrous calcium chloride solid at a molar ratio of 2:1 in an aqueous solution with pH = 8, stir and react at 80°C for 1 hour, then concentrate under reduced pressure and suction to a sticky paste. The precipitate was washed 4 times with absolute ethanol. Finally, the precipitate was dried in a vacuum oven at 50 °C for 24 h for use.

[0038] Preparation of composite nanofiltration membrane:

[0039] Prepare an Asp-Ca aqueous solution with a mass concentration of 0.01w / v%, a 0.1w / v% PIP aqueous solution, and a 0.1w / v% TMC n-decane solution.

[0040] First, cut the polysulfone ultrafiltration base membrane with a molecular weight cut off of 5000 to an appropriate size, and place it on the mouth of the suction filter bottle (effective filtration area 20cm 2 ), pour 30mL of prepared Asp-Ca aqueous solution into the suction filter cup, that is, the suction filtration volum...

Embodiment 2

[0042] Preparation of Glu-Cu metal chelates:

[0043] Heat and dissolve L-glutamic acid powder and copper sulfate pentahydrate crystals with a molar ratio of 2:1 in an aqueous solution of pH=6, stir and react in a water bath at 85°C for 1 hour, cool the reaction solution, and filter under reduced pressure in batches , adding absolute ethanol to wash the precipitate for 4 times, taking the filter cake layer and drying it in an oven at 110°C to constant weight to obtain blue Glu-Cu crystals, which were stored in a vacuum desiccator.

[0044] Preparation of composite nanofiltration membrane:

[0045] Prepare an Asp-Ca aqueous solution with a mass concentration of 0.01w / v%, a 0.2w / v% PIP aqueous solution, and a 0.2w / v% TMC n-decane solution.

[0046] First, cut the polysulfone ultrafiltration base membrane with a molecular weight cut off of 5000 to an appropriate size, and place it on the mouth of the suction filter bottle (effective filtration area 20cm 2 ), pour 30mL of prepar...

Embodiment 3

[0048] Preparation of Glu-Cu metal chelate: same as Example 2.

[0049] Preparation of composite nanofiltration membrane:

[0050] The Glu-Cu aqueous solution with a mass concentration of 0.05w / v%, the PIP aqueous solution with 1.0w / v%, and the TMC n-decane solution with 0.2w / v% were prepared.

[0051] First, cut the polysulfone ultrafiltration base membrane with a molecular weight cut off of 10,000 to an appropriate size, and place it on the mouth of the suction filter bottle (effective filtration area 20cm 2 ), pour 10mL of the prepared Glu-Cu aqueous solution into the suction filter cup, that is, the suction filtration volume is 0.5mL / cm 2 (relative to the area of the base membrane), vacuumize and filter the moisture under the condition of 0.02MPa (absolute pressure), and obtain a polysulfone base membrane with a layer of Glu-Cu deposited on the surface. Then soak it in the water phase solution for 10 minutes, remove excess water on the surface with filter paper after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com