Ceramic material integrating high energy storage density and efficiency, and preparation method thereof

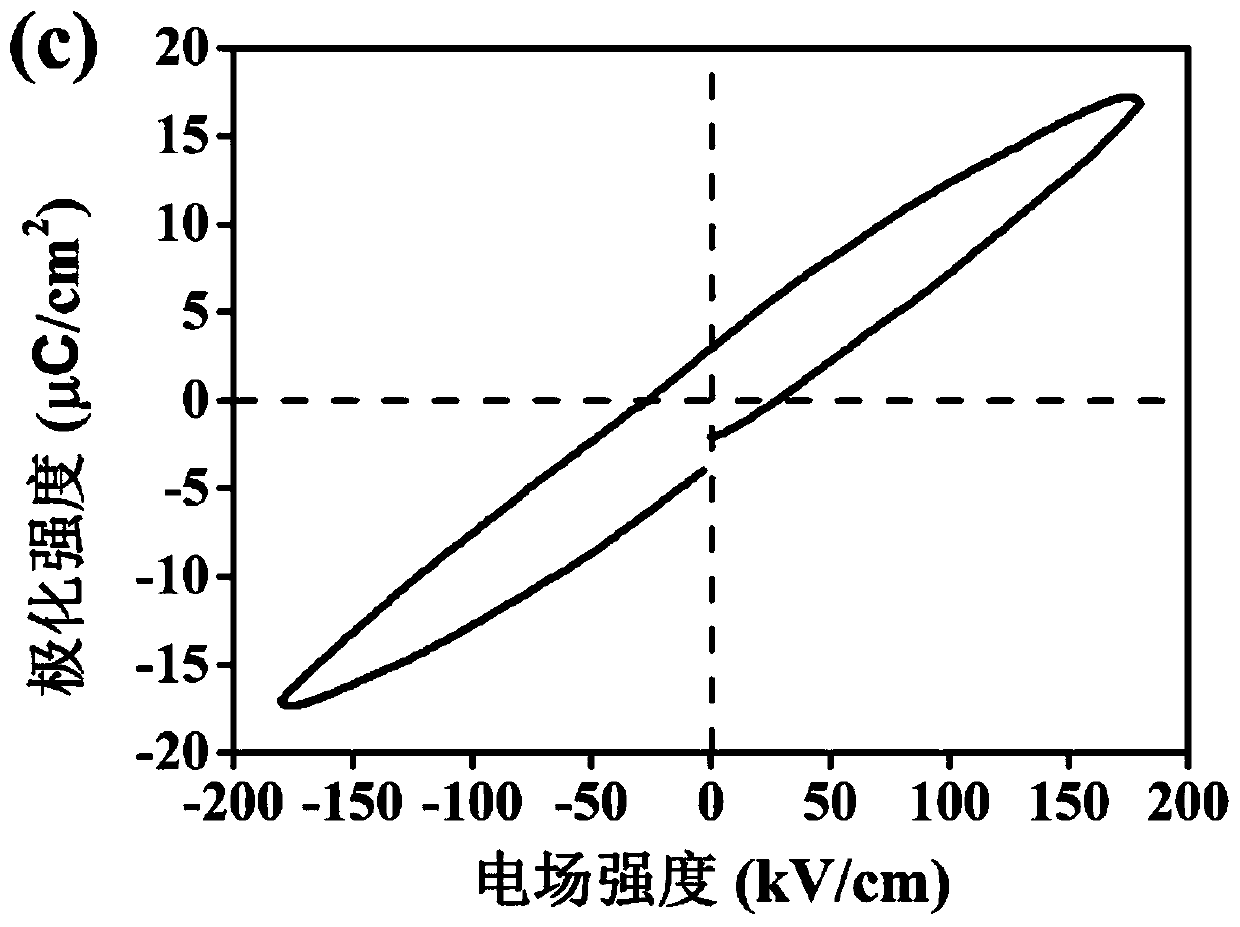

A technology of high energy storage density and ceramic materials, which is applied in the field of sodium niobate-based ceramic materials and its preparation, can solve the problems of limited practical application, difficulty in high energy storage density and high energy storage efficiency, and achieve easy mass production, High energy storage density, the effect of reducing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

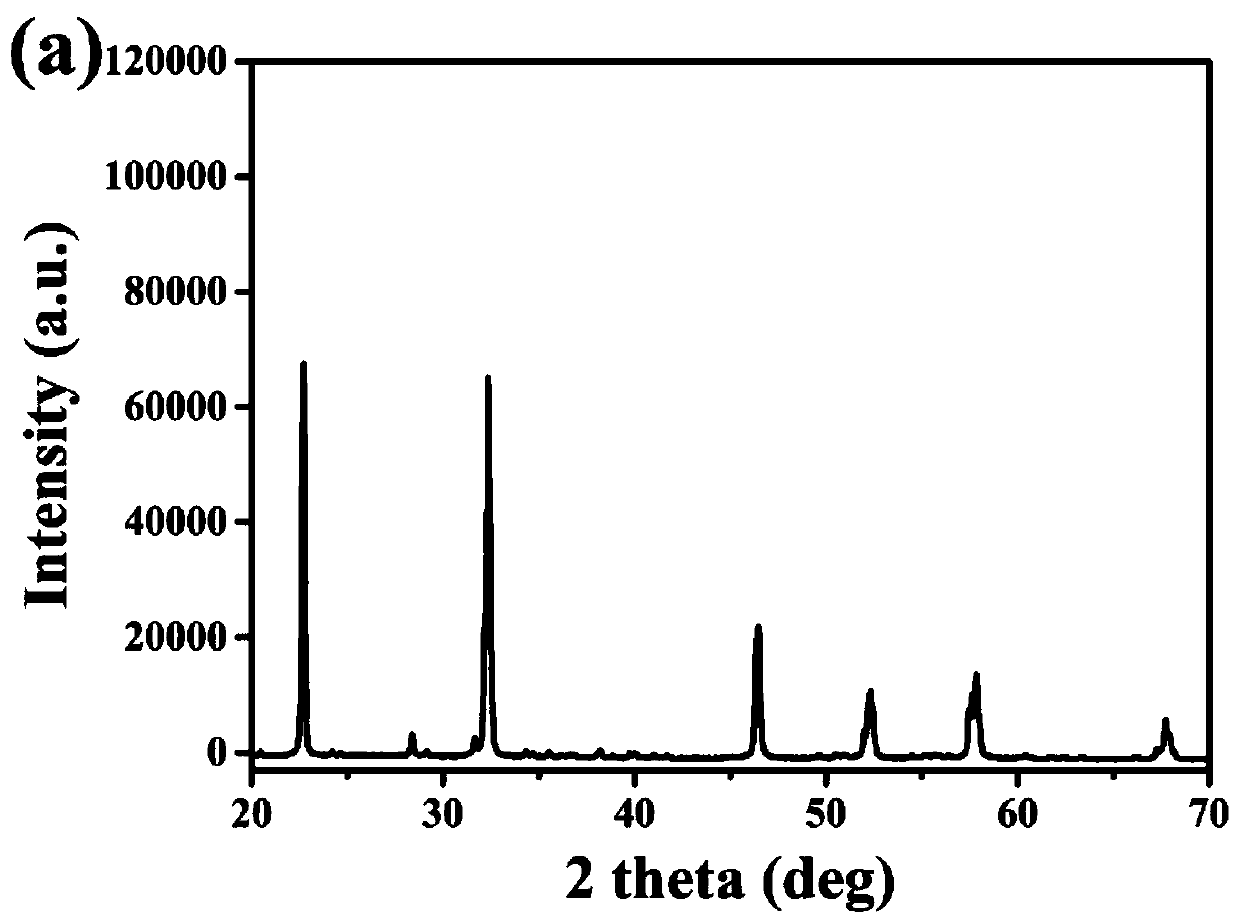

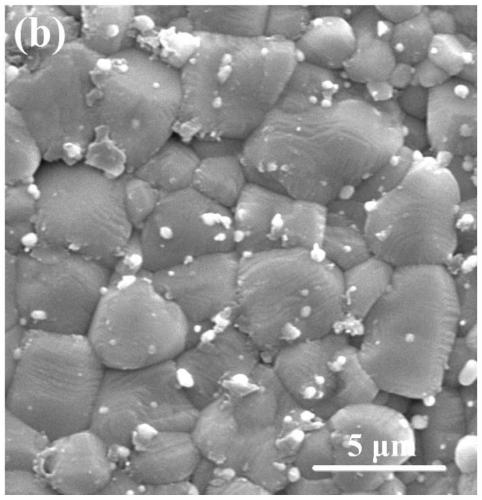

[0043] S1. Calculation and weighing: After drying the raw materials of analytically pure anhydrous sodium carbonate, niobium pentoxide, bismuth trioxide and hafnium dioxide at 120°C for 15 hours, according to the chemical formula 0.95NaNbO 3 -0.05 (Bi 0.5 Na 0.5 )HfO 3 The stoichiometric ratio in the above-mentioned raw materials was weighed, and poured into a ball mill jar to obtain a mixture;

[0044] S2, ball milling: the mixture obtained in step S1 is mixed with ZrO in ethanol 2 The ball is a medium planetary ball mill for 12 hours, dried and sieved to obtain a dry powder;

[0045] S3. Pre-calcination: pre-calcine the dry powder obtained in step S2 in air at 920° C. for 5 hours, grind and sieve to obtain powder A;

[0046] S4, multiple ball milling: the powder A obtained in step S3 is planetary ball milled in ethanol for 12 hours, after drying, the powder is then planetary ball milled in ethanol for 12 hours, ball milled three times in turn, and finally dried to obtain...

Embodiment 2

[0057] S1. Calculation and weighing: After drying the raw materials of analytically pure anhydrous sodium carbonate, niobium pentoxide, bismuth trioxide and hafnium dioxide at 140°C for 13 hours, according to the chemical formula 0.92NaNbO 3 -0.08 (Bi 0.5 Na 0.5 )HfO 3 The stoichiometric ratio in the above-mentioned raw materials was weighed, and poured into a ball mill jar to obtain a mixture;

[0058] S2, ball milling: the mixture obtained in step S1 is mixed with ZrO in ethanol 2 The ball is a medium planetary ball mill for 15 hours, dried and sieved to obtain a dry powder;

[0059] S3. Pre-calcination: pre-calcine the dry powder obtained in step S2 in air at 900°C for 8 hours, grind and sieve to obtain powder A;

[0060] S4, multiple ball milling: the powder material A obtained in step S3 was planetary ball milled in ethanol for 15 hours, after drying, the powder material was planetary ball milled in ethanol for 20 hours, ball milled twice in turn, and finally dried to...

Embodiment 3

[0069] S1. Calculation and weighing: After drying the raw materials of analytically pure anhydrous sodium carbonate, niobium pentoxide, bismuth trioxide and hafnium dioxide at 150°C for 10 hours, according to the chemical formula 0.89NaNbO 3 -0.11 (Bi 0.5 Na 0.5 )HfO 3 The stoichiometric ratio in the above-mentioned raw materials was weighed, and poured into a ball mill jar to obtain a mixture;

[0070] S2, ball milling: the mixture obtained in step S1 is mixed with ZrO in ethanol 2 The ball is a medium planetary ball mill for 20 hours, dried and sieved to obtain a dry powder;

[0071] S3. Pre-calcination: pre-calcine the dry powder obtained in step S2 in air at 890°C for 10 hours, grind and sieve to obtain powder A;

[0072] S4, multiple ball milling: the powder A obtained in step S3 was planetary ball milled in ethanol for 15 hours, after drying, the powder was then planetary ball milled in ethanol for 12 hours, ball milled three times in turn, and finally dried to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com