A kind of mns@comn-ldh composite material and its preparation method and application

A composite material and thermal reaction technology, which is applied in the field of electrochemistry and nanomaterials, can solve the problems of unsatisfactory electrochemical performance, limited application, low conductivity, etc., and achieve rich electrolyte diffusion channels, simple preparation methods, and high current density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

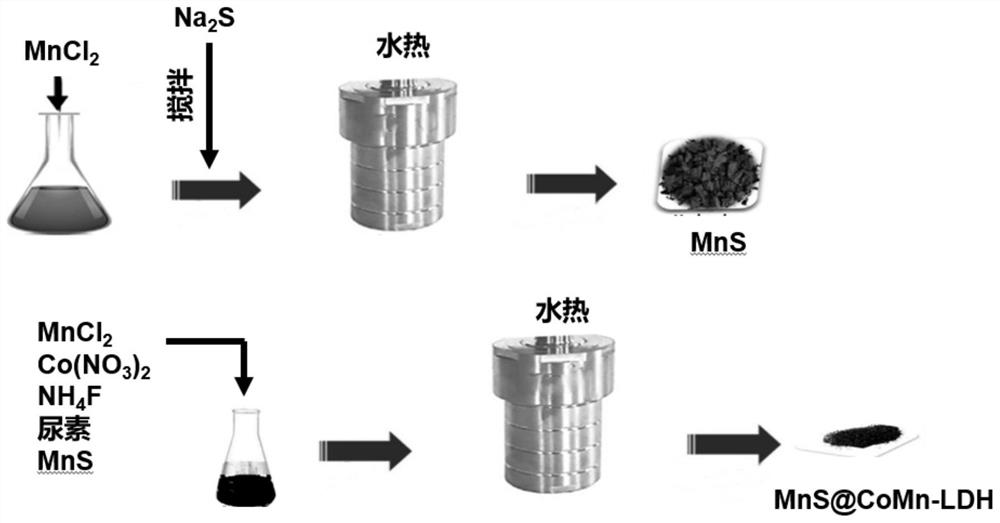

[0031] A kind of preparation method of MnS@CoMn-LDH composite material such as figure 1 shown, including the following steps:

[0032] The first step is hydrothermal, 0.1g MnCl 2 4H 2 O was dissolved in 25mL of deionized water, and 5mL of 0.1mol / L Na 2 S, after magnetic stirring for 20min, transfer to a 50mL polytetrafluoroethylene-lined stainless steel autoclave for the first step of hydrothermal reaction, the hydrothermal reaction temperature is 120°C, and the hydrothermal reaction time is 8h; Take it out to cool, then centrifuge, wash, and vacuum dry at 60°C for 12 hours to obtain MnS powder. In the second step of hydrothermal treatment, 1mmolMnCl 2 4H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 5 mmol NH 4 F, 5mmol urea was dissolved in deionized water, and after magnetic stirring for 30min, the MnS sample prepared by hydrothermal treatment in the first step was added, and after it was mixed evenly, it was transferred to a polytetrafluoroethylene-lined stainless steel autocla...

Embodiment 2

[0035] A preparation method of MnS@CoMn-LDH composite material, comprising the following steps:

[0036] The first step is hydrothermal, 0.1g MnCl 2 4H 2 O was dissolved in 25mL of deionized water, and 5mL of 0.1mol / L Na 2 S, after magnetic stirring for 20min, transfer to a 50mL polytetrafluoroethylene-lined stainless steel autoclave for the first step of hydrothermal reaction, the hydrothermal reaction temperature is 150°C, and the hydrothermal reaction time is 8h; Take it out to cool, then centrifuge, wash, and vacuum dry at 60°C for 12 hours to obtain MnS powder. In the second step of hydrothermal treatment, 1mmolMnCl 2 4H2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 5 mmol NH 4 F, 5mmol urea was dissolved in deionized water, and after magnetic stirring for 30min, the MnS sample prepared by hydrothermal treatment in the first step was added, and after it was mixed evenly, it was transferred to a polytetrafluoroethylene-lined stainless steel autoclave for the second step of water h...

Embodiment 3

[0039] A preparation method of MnS@CoMn-LDH composite material, comprising the following steps:

[0040] The first step is hydrothermal, 0.1g MnCl 2 4H 2 O was dissolved in 25mL of deionized water, and 5mL of 0.1mol / L Na 2 S, after magnetic stirring for 20min, transfer to a 50mL polytetrafluoroethylene-lined stainless steel autoclave for the first step of hydrothermal reaction, the hydrothermal reaction temperature is 120°C, and the hydrothermal reaction time is 12h; Take it out to cool, then centrifuge, wash, and vacuum dry at 60°C for 12 hours to obtain MnS powder. In the second step of hydrothermal treatment, 1mmolMnCl 2 4H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 5 mmol NH 4 F, 5mmol urea was dissolved in deionized water, and after magnetic stirring for 30min, the MnS sample prepared by hydrothermal treatment in the first step was added, and after it was mixed evenly, it was transferred to a polytetrafluoroethylene-lined stainless steel autoclave for the second step of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com