Method for reduction and detoxification of hazardous waste sludge

A technology for waste sludge and sludge, applied in the fields of sludge detoxification, sludge treatment, biological sludge treatment, etc., can solve the problems of secondary pollution reduction effect, long treatment time, high treatment cost, and achieve environmental benefits And the effect of good social benefit, increasing concentration and high sludge reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

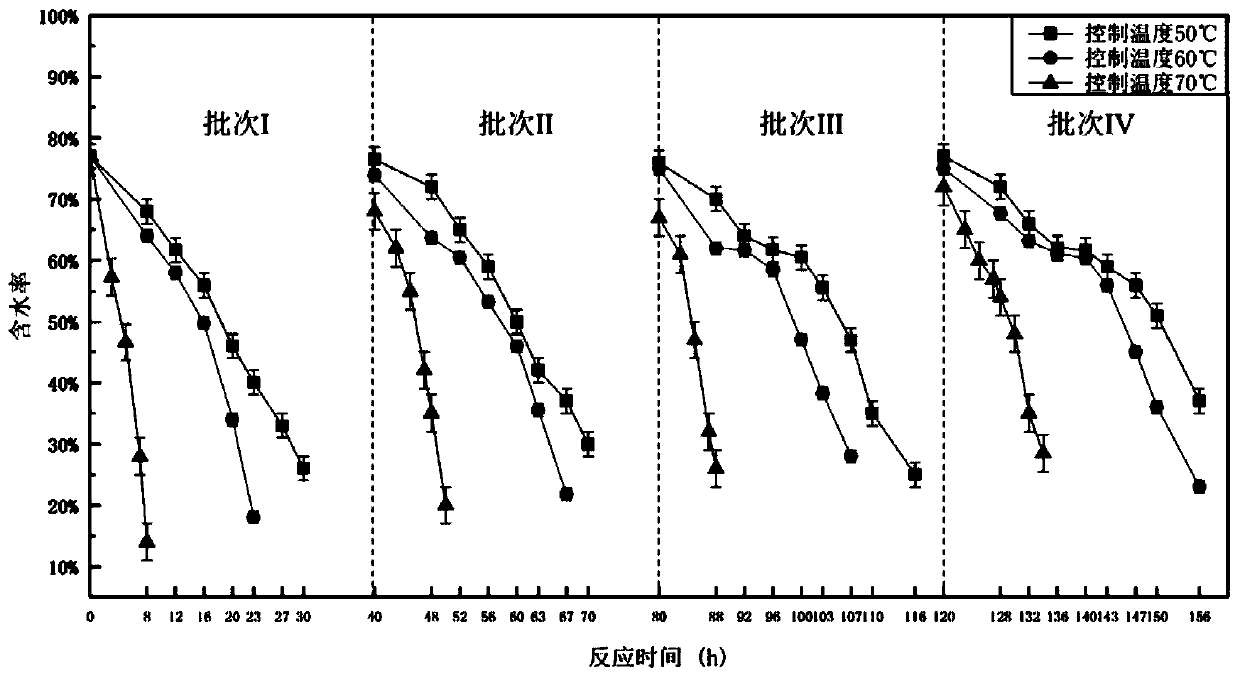

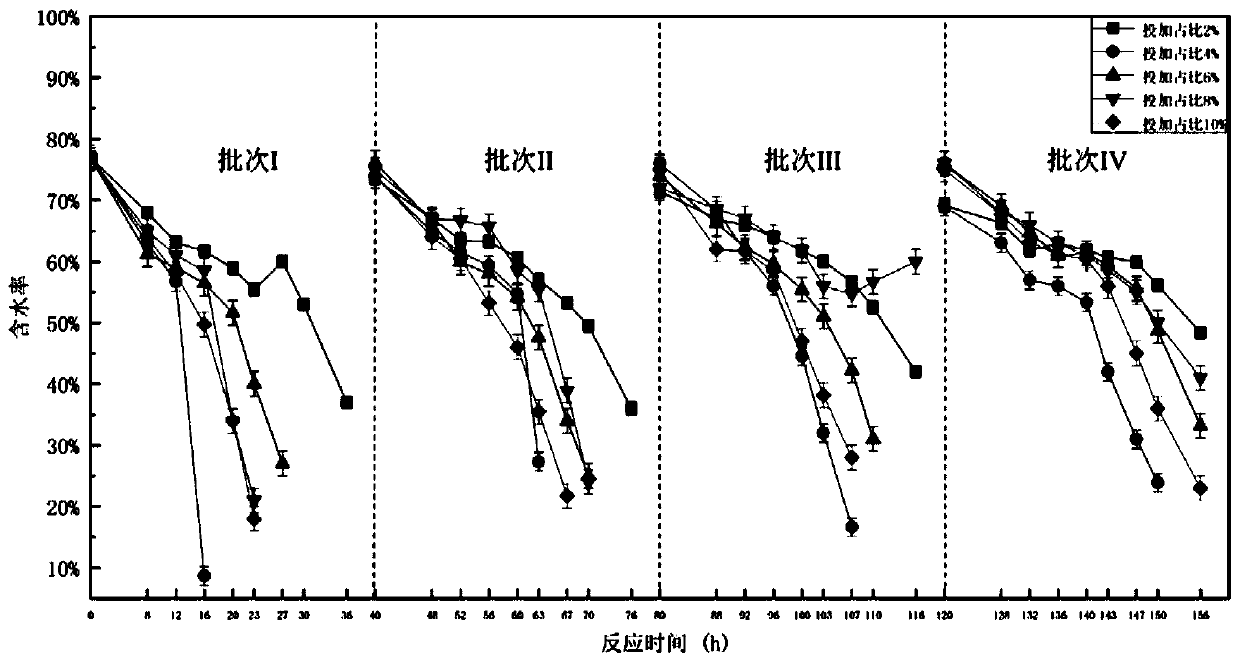

[0035] Embodiment 1, determine the optimal condition of sludge detoxification

[0036] The sludge used is sewage sludge from a chemical fiber factory. The content of manganese, a toxic substance, and cobalt sulfate, a carcinogen, are 416,000 mg / kg. GB5085.6-2007) is defined as hazardous waste.

[0037] The method for reducing and detoxifying hazardous waste sludge includes the following steps:

[0038] The water content of the mud was 84.2% through plate and frame pressure filtration, and four batches were fed continuously. The first batch of materials was directly added with the above-mentioned sludge, auxiliary materials sawdust and microbial agents, wherein the amount of auxiliary materials added sawdust was 2% of the dry weight of the sludge. 50%, mixed evenly; the amount of microbial agent added is 2% of the dry weight of the sludge, and it is added at one time. The second batch of materials is directly added with the same amount of sludge and auxiliary material shaving...

Embodiment 2

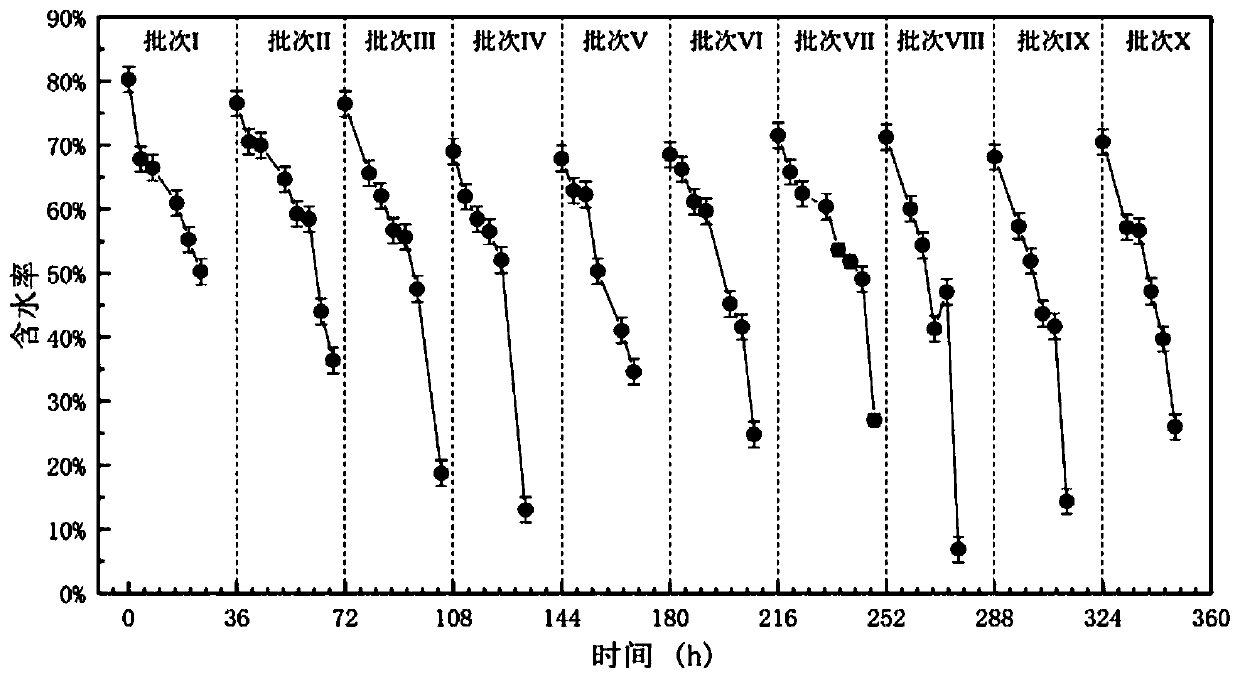

[0043] Continuous reaction effect under embodiment 2, optimum condition

[0044] The mixed feed is added at one time, and the dosage of the biological agent accounts for 4% of the dry weight of the sludge. The microbial agent is 30 parts of Bacillus stearothermophilus photosynthetic bacteria, 15 parts of Sinibacillus, 15 parts of Bacillus SPP., 10 parts of photosynthetic bacteria, 10 parts of lactic acid bacteria, 10 parts of actinomycetes and 10 parts of fungi. The set temperature of the equipment is 60°C, the sludge is aerated by forced ventilation, the ventilation rate is 0.55L / min, and 20 batches are continuously reacted.

[0045] Real-time measurement of processing effects, image 3 For the dehydration effect of continuous reaction, it can be seen that in the continuous reaction process, the dehydration rate of each batch is basically consistent, but with the continuous reaction, the degree of dehydration is getting higher and higher, and the dry matter reduction rate re...

Embodiment 3

[0046] Continuous reaction effect under embodiment 3, optimum condition

[0047] The mixed feed is added at one time, and the dosage of the biological agent accounts for 4% of the dry weight of the sludge. The microbial agent is 35 parts of Bacillus stearothermophilus photosynthetic bacteria, 15 parts of Sinibacillus, 10 parts of Bacillus SPP., 10 parts of photosynthetic bacteria, 10 parts of lactic acid bacteria, 10 parts of actinomycetes and 10 parts of fungi. The set temperature of the equipment is 75°C, the sludge is aerated by forced ventilation, the ventilation rate is 0.6L / min, and 20 batches are reacted continuously. The treatment effect was measured in real time. During the continuous reaction, the dehydration rate of each batch remained basically the same, but as the continuous reaction proceeded, the degree of dehydration became higher and higher. The dry matter reduction rate reached 18%, and the detoxification rate was 9%. The moisture content of the sludge is 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com