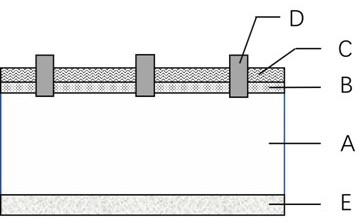

A kind of conductive paste and semiconductor device made of it

A technology of conductive paste and air duct, which is applied to conductive materials, semiconductor devices, circuits, etc. dispersed in non-conductive inorganic materials, can solve the problem that the pattern uniformity needs to be further improved, and achieve good printability and excellent plasticity. , the effect of neat graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Synthesis of Vinylpyrrolidone Microgel PVP Microgel

[0059] A 1000mL four-necked bottle is equipped with a dropping funnel, a reflux condenser, a thermometer and an air guide tube, and placed in a constant temperature water bath. Add 400.0g of cyclohexane and 0.80g of emulsified water with a mass ratio of 4:1 to the bottle in sequence. Agents Span 80 and Tween 80, stirred under nitrogen to make the layer a transparent oil phase solution. Add an ice pack to control the temperature of the water bath at around 0°C. Dissolve 25.0 g of N-vinylpyrrolidone (NVP), 0.08 g of N,N'-methylenebisacrylamide (MBA) and 0.021 g of ammonium persulfate (APS) in 40 g of deionized water under continuous stirring for half an hour Slowly add the aqueous solution dropwise to the above emulsified oil phase solution. After half an hour of reaction, 100 μL of tetramethylethylenediamine (TMEDA) was added, the temperature was gradually raised to 20° C., and the reaction was terminated after stir...

Embodiment 2

[0067] Synthesis of Acrylamide Microgel PDMAM Microgel

[0068] A 1000mL four-necked bottle is equipped with a dropping funnel, a reflux condenser, a thermometer and an air guide tube, and placed in a constant temperature water bath. Add 400.0g of cyclohexane and 0.80g of emulsified water with a mass ratio of 3:1 to the bottle in sequence. Agents Span 80 and Tween 80, magnetically stirred under the condition of nitrogen gas to make the layer into a transparent oil phase solution. Add an ice pack to control the temperature of the water bath at around 0°C. Dissolve 20.0 g of N,N'-dimethylacrylamide (DMAM), 0.12 g of N,N'-methylenebisacrylamide (MBA) and 0.018 g of ammonium persulfate (APS) in 40 g of In deionized water, slowly add the aqueous solution dropwise to the above-mentioned emulsified oil phase solution within half an hour. After half an hour of reaction, 100 μL of tetramethylethylenediamine (TMEDA) was added, the temperature was gradually raised to 20° C., and the re...

Embodiment 3

[0073] Synthesis of Acrylic Microgels

[0074] A 1000mL four-necked bottle is equipped with a dropping funnel, a reflux condenser, a thermometer and an air guide tube, and placed in a constant temperature water bath. Add 450g of deionized water to the bottle and heat it to 85°C. Then add 400mg sodium dodecylsulfonate (SDS) and 1.4g7%KH 2 PO 4Solution (pH value about 7), respectively add 92g methyl methacrylate (MMA) and 276mg ethylene glycol dimethacrylate (EGDMA) crosslinking agent into a beaker to make a monomer mixture. About 30 mL of the monomer mixture was added to the flask. After stirring was started, 1.1 g of a 5 wt % solution of ammonium persulfate (APS) initiator in water was slowly added. At the same time, the remaining monomer mixture was continuously added dropwise within 1.5 h. After continuing to react for 4 h, the reaction was terminated. The emulsion was freeze-dried, and then washed with acetone to remove emulsifiers, surfactants and unreacted monomers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com