A preparation method of single crystal ternary lithium battery cathode material and lithium ion battery

A technology for ternary lithium batteries and positive electrode materials, applied in battery electrodes, polycrystalline material growth, single crystal growth, etc., can solve poor cycle performance and thermal stability, low volume energy density, poor order and stability, etc. problem, to achieve the effect of improving the binding performance, firm structure and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

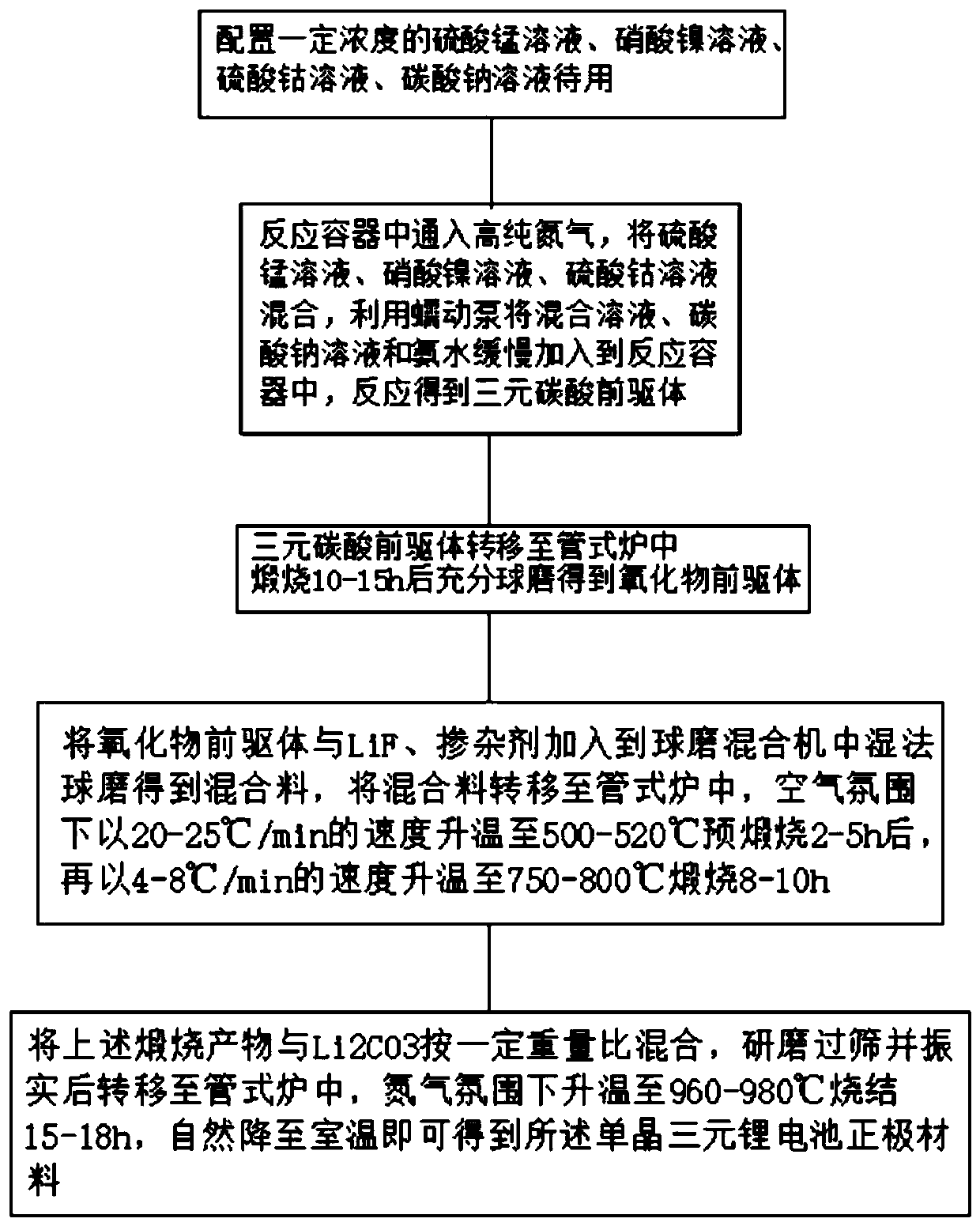

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a single crystal ternary lithium battery cathode material is as follows:

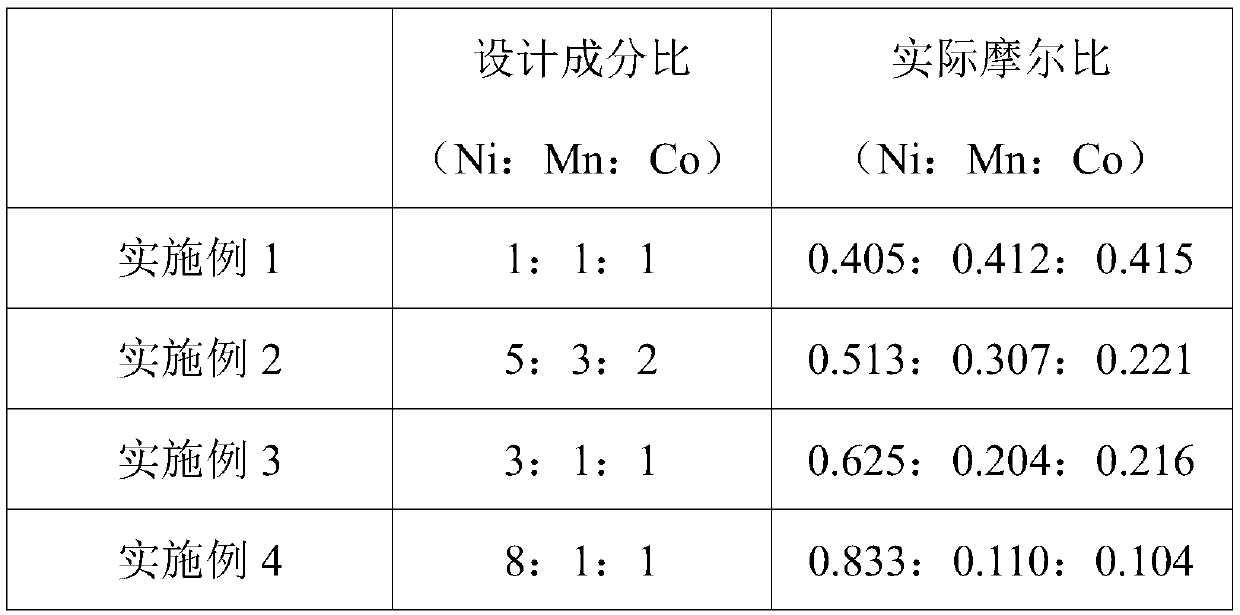

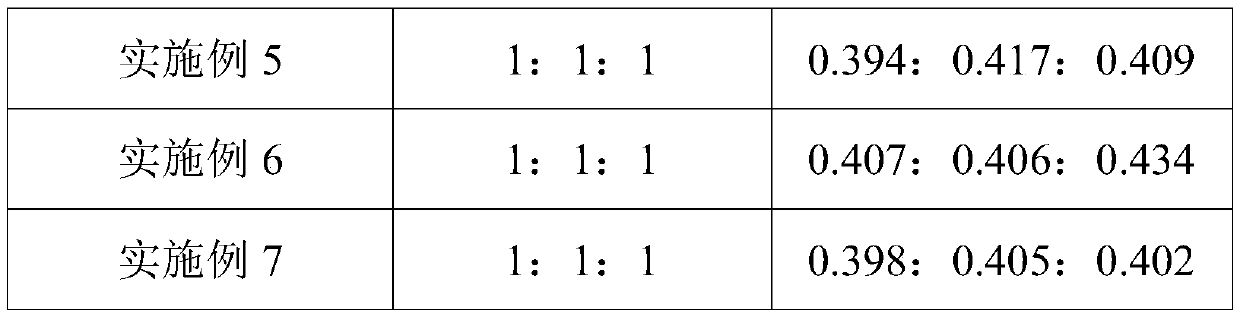

[0031]Configure 1mol / L manganese sulfate solution, 1mol / L nickel nitrate solution, 1mol / L cobalt sulfate solution, and 0.1mol / L sodium carbonate solution for use, and feed high-purity nitrogen into the stirred reaction vessel. Mix 500ml each of manganese sulfate solution, nickel nitrate solution, and cobalt sulfate solution in advance to obtain a mixed solution, and use a peristaltic pump to slowly add the mixed solution, 15L sodium carbonate solution and 50ml ammonia water (mass concentration: 25%) into the reaction vessel at the same time , control the pH in the reaction vessel to be 7.5-8, the reaction temperature is 50°C, the stirring speed is 150r / min, the stirring reaction is turned off after 10 hours of stirring, the heat preservation is left to stand for 2 hours, and then the room temperature is returned to continue to stand for 10 hours, and suction filtration The...

Embodiment 2

[0033] A preparation method of a single crystal ternary lithium battery cathode material is as follows:

[0034] Configure 0.8mol / L manganese sulfate solution, 5mol / L nickel nitrate solution, 1.5mol / Lmol / L cobalt sulfate solution, and 0.5mol / L sodium carbonate solution for use, and feed into the stirred reaction vessel High-purity nitrogen, mix each 500ml of manganese sulfate solution, nickel nitrate solution, and cobalt sulfate solution to obtain a mixed solution, and use a peristaltic pump to slowly add the mixed solution, 10L sodium carbonate solution and 50ml ammonia (mass concentration is 25%) to the In the reaction vessel, control the pH in the reaction vessel to be 7.5-8, the reaction temperature to be 55°C, and the stirring speed to be 200r / min. After stirring for 6 hours, turn off the stirring, keep the temperature for 2 hours, and return to room temperature for 10 hours. , the obtained solid was fully washed and dried by suction filtration to obtain the ternary carbo...

Embodiment 3

[0036] A preparation method of a single crystal ternary lithium battery cathode material is as follows:

[0037] Configure 0.67mol / L manganese sulfate solution, 2mol / L nickel nitrate solution, 0.67mol / L cobalt sulfate solution, and 0.2mol / L sodium carbonate solution for use, and pass high-purity Nitrogen, each 500ml of manganese sulfate solution, nickel nitrate solution, and cobalt sulfate solution are pre-mixed uniformly to obtain a mixed solution, and a peristaltic pump is used to slowly add the mixed solution, 8.3L sodium carbonate solution and 50ml ammonia (mass concentration is 25%) to the In the reaction vessel, control the pH in the reaction vessel to be 7.5-8, the reaction temperature to be 50°C, and the stirring speed to be 200r / min. After stirring and reacting for 6 hours, turn off the stirring, keep the heat preservation for 2 hours, return to room temperature and continue to stand for 6 hours. , the obtained solid was fully washed and dried by suction filtration to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com