Method for preparing polysaccharide composite film by thermally stable recombinant bacterial laccase and application

A technology of polysaccharide compounding and laccase, applied in the direction of biochemical equipment and methods, applications, chitin polysaccharide coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

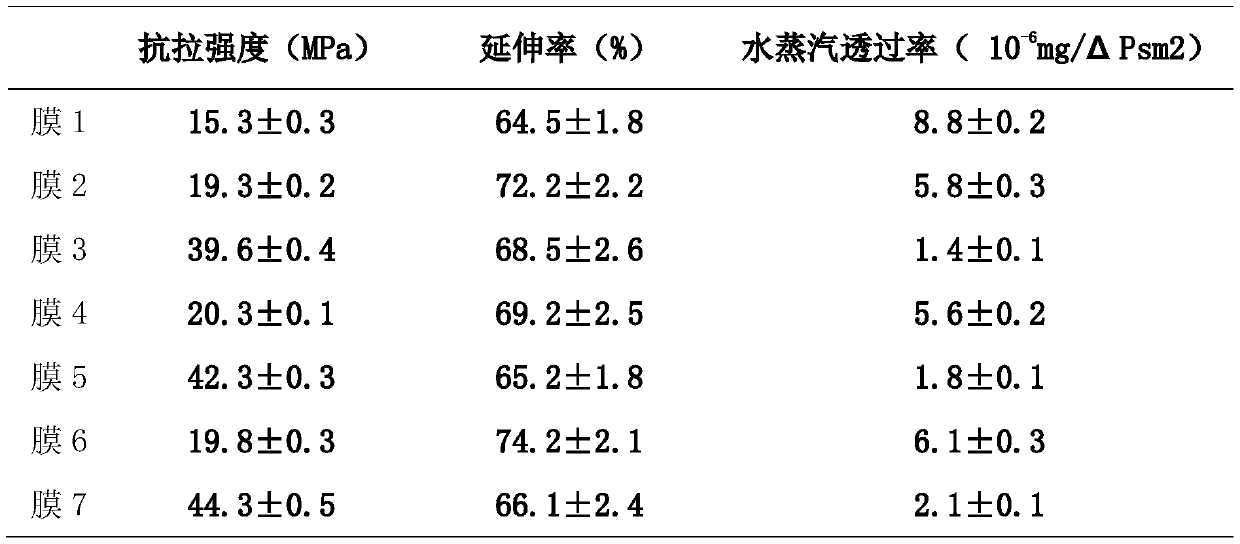

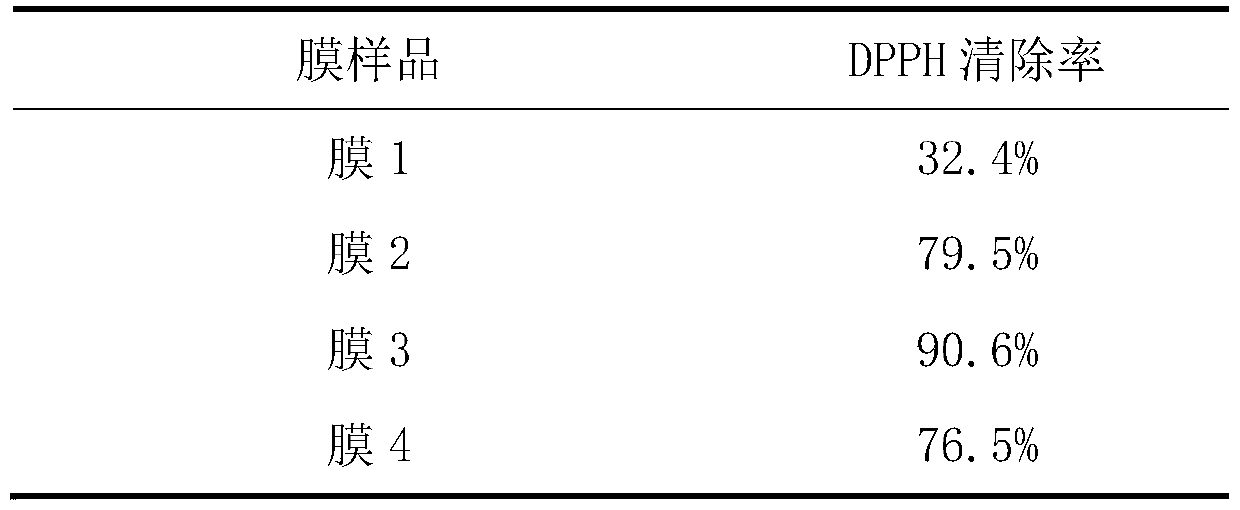

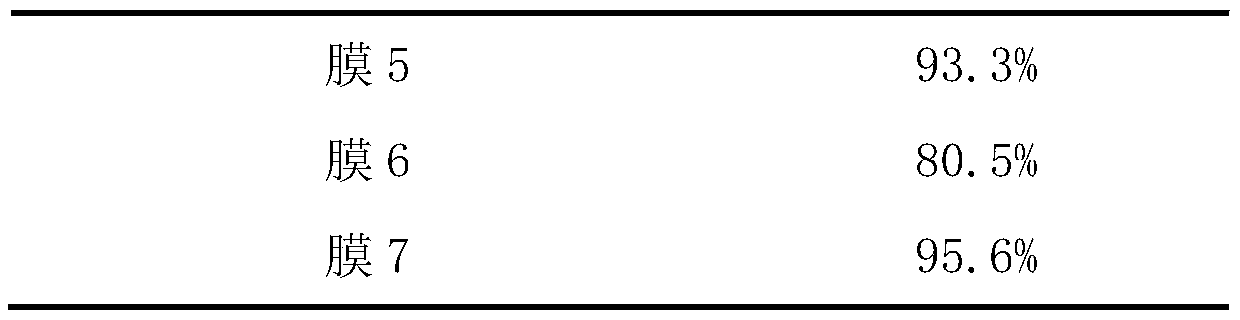

Examples

Embodiment 1

[0051] Embodiment 1: Composite membrane preparation process

[0052] (1) Weigh 8g of Curdlan polysaccharide powder, dissolve in pure water, and after Curdlan is fully swollen, prepare 8g / 100mL of Curdlan suspension under the action of a high-speed shear;

[0053] (2) Add 1g carboxymethyl chitosan, 0.2g bacterial cellulose, and 0.1g chlorogenic acid to 50mL Curdlan suspension, and prepare suspension A under the action of a magnetic stirrer

[0054] (3) Add 0.3 g of glycerin and 0.3 g of Tween 80 to the suspension A in step (2), dilute to 100 mL with pure water, and prepare suspension B under the action of a magnetic stirrer;

[0055] (4) Adjust the pH to 4 with 2mol / L hydrochloric acid, homogenize with a homogenizer, degas with ultrasound, add 10U of heat-stable recombinant bacterial laccase (Lac) to obtain a film-forming solution;

[0056] (5) Pour the film-forming solution into a polytetrafluoroethylene plate; 60°C enzyme-catalyzed reaction for 40 minutes;

[0057] (6) Ultr...

Embodiment 2

[0060] Embodiment 2: Composite membrane preparation process

[0061] (1) Weigh 12g of Curdlan polysaccharide powder, dissolve in pure water, and after Curdlan is fully swollen, under the action of a high-speed shear, prepare 12g / 100mL of Curdlan suspension;

[0062] (2) Add 1.5g carboxymethyl chitosan, 0.4g bacterial cellulose, and 0.1g catechin to 50mL Curdlan suspension, and prepare suspension A under the action of a magnetic stirrer;

[0063] (3) Add 0.5 g of glycerin and 0.5 g of Tween 80 to the suspension A in step (2), dilute to 100 mL with pure water, and prepare suspension B under the action of a magnetic stirrer;

[0064] (4) Adjust the pH to 4 with 2mol / L hydrochloric acid, homogenize with a homogenizer, degas with ultrasound, add 15U of heat-stable recombinant bacterial laccase (Lac) to obtain a film-forming solution;

[0065] (5) Pour into a polytetrafluoroethylene plate; 60 ° C enzyme-catalyzed reaction for 40 minutes;

[0066] (6) Ultraviolet radiation steriliz...

Embodiment 3

[0069] Embodiment 3: Composite membrane preparation process

[0070] (1) Weigh 16g of Curdlan polysaccharide powder, dissolve in pure water, and after Curdlan is fully swollen, under the action of high-speed shearing machine, prepare 16g / 100mL of Curdlan suspension;

[0071] (2) Add 2g carboxymethyl chitosan, 0.6g bacterial cellulose, and 0.1g gallic acid to 50mL Curdlan suspension, and prepare suspension A under the action of a magnetic stirrer;

[0072] (3) Add 0.3 g of sorbitol and 0.3 g of Span to the suspension A in step (2), dilute to 100 mL with pure water, and prepare suspension B under the action of a magnetic stirrer;

[0073] (4) Adjust the pH to 4 with 2mol / L hydrochloric acid, homogenize with a homogenizer, degas with ultrasound, add 10U of heat-stable recombinant bacterial laccase (Lac) to obtain a film-forming solution;

[0074] (5) Pour into a polytetrafluoroethylene plate; 60 ° C enzyme-catalyzed reaction for 40 minutes;

[0075] (6) Ultraviolet radiation st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com