Low-warpage polybutylene terephthalate (PBT) composite material with stable size, and preparation method of composite material

A composite material and dimensionally stable technology, applied in the field of plastics, can solve the problems of inconsistent longitudinal and transverse shrinkage, product warping, etc., and achieve the effects of improving flow performance, preventing warping, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of dimensionally stable and low warpage PBT composite material, wherein the preparation method comprises the steps of:

[0035] 1) Polybutylene terephthalate, polyether ether ketone, maleic anhydride grafted polyethylene, myristyl myristate, carboxylated nitrile latex, chlorinated polyethylene, calcium stearate, ethylene-acrylic acid Copolymer, N-benzylamine phenylenediamine, thiobisphenol, zeolite, oleic acid, and cobalt oxide are stirred and mixed to obtain the first mixture; 2) the above-mentioned mixed materials are put into a twin-screw extruder, and melted, kneaded, Extruding, cooling, drying, pelletizing and packaging to obtain the PBT composite material.

Embodiment 1

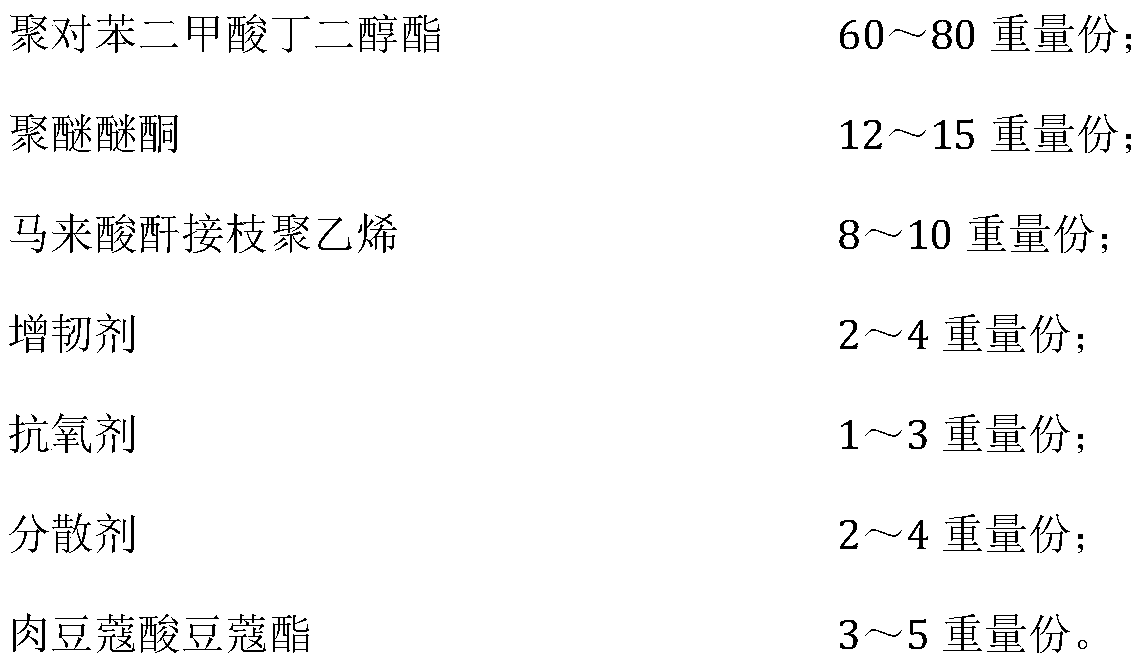

[0038] A dimensionally stable and low-warp PBT composite material, comprising the following materials in parts by weight:

[0039]

[0040] Toughening agent includes 30wt% carboxyl nitrile latex and 70wt% chlorinated polyethylene; Dispersant includes 60wt% calcium stearate and 40wt% ethylene-acrylic acid copolymer; Antioxidant includes 20wt% N-benzylamine phenylenediamine and 80 wt% thiobisphenol; the particle diameter of zeolite is 60nm; the number average molecular weight of polyether ether ketone is 3200.

[0041] A preparation method of a dimensionally stable and low warpage PBT composite material, the preparation method comprising the steps of:

[0042]1) Polybutylene terephthalate, polyether ether ketone, maleic anhydride grafted polyethylene, myristyl myristate, carboxylated nitrile latex, chlorinated polyethylene, calcium stearate, ethylene-acrylic acid Copolymer, N-benzylamine phenylenediamine, thiobisphenol, zeolite, oleic acid, and cobalt oxide are stirred and m...

Embodiment 2

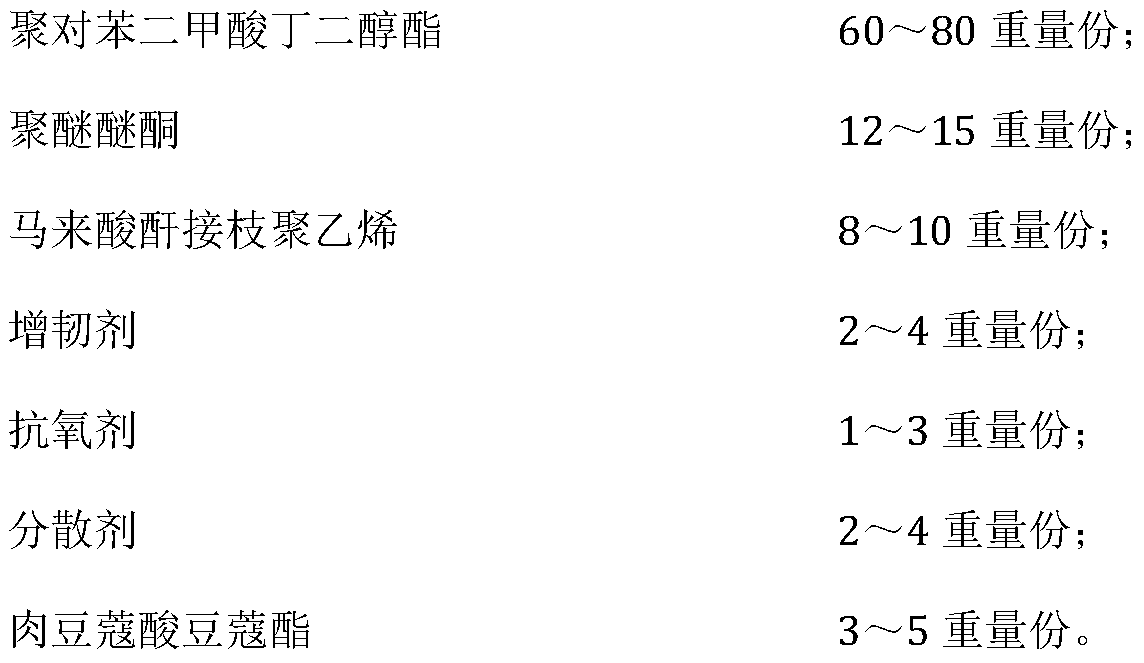

[0044] A dimensionally stable and low-warp PBT composite material, comprising the following materials in parts by weight:

[0045]

[0046] Toughening agent includes 32wt% carboxyl nitrile latex and 68wt% chlorinated polyethylene; Dispersant includes 63wt% calcium stearate and 37wt% ethylene-acrylic acid copolymer; Antioxidant includes 24wt% N-benzylamine phenylenediamine and 76 wt% thiobisphenol; the particle size of zeolite is 70nm; the number average molecular weight of polyether ether ketone is 3300.

[0047] A preparation method of a dimensionally stable and low warpage PBT composite material, the preparation method comprising the steps of:

[0048] 1) Polybutylene terephthalate, polyether ether ketone, maleic anhydride grafted polyethylene, myristyl myristate, carboxylated nitrile latex, chlorinated polyethylene, calcium stearate, ethylene-acrylic acid Copolymer, N-benzylamine phenylenediamine, thiobisphenol, zeolite, oleic acid, and cobalt oxide are stirred and mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com