A surface coating agent and process for treating drilling solidified waste

A technology of surface coating and coating process, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, special surface, etc., can solve the problems of poor environmental adaptability, achieve enhanced curing bonding strength, improve hydrophobicity, and ensure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

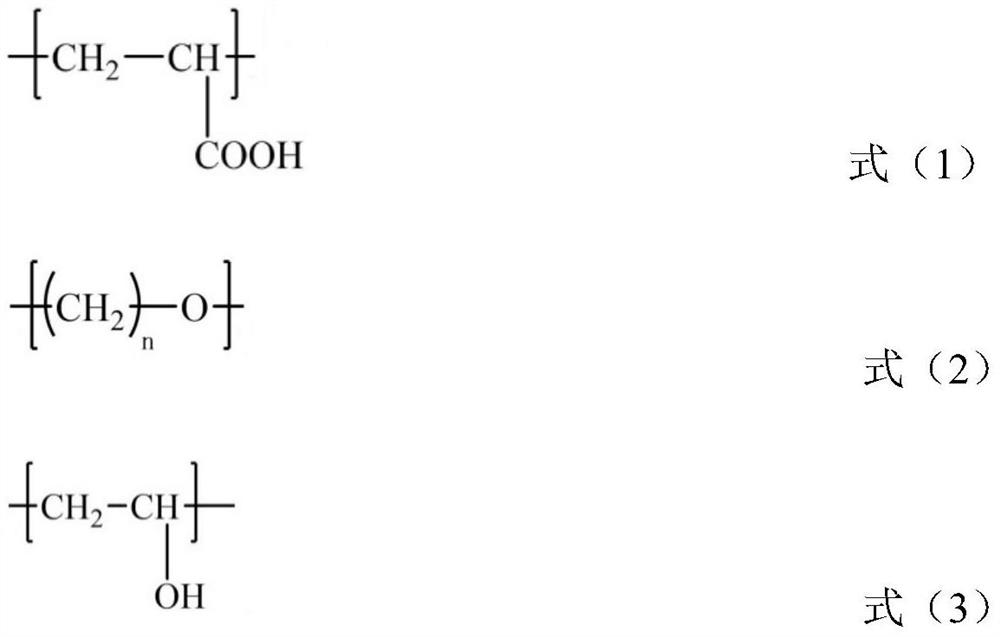

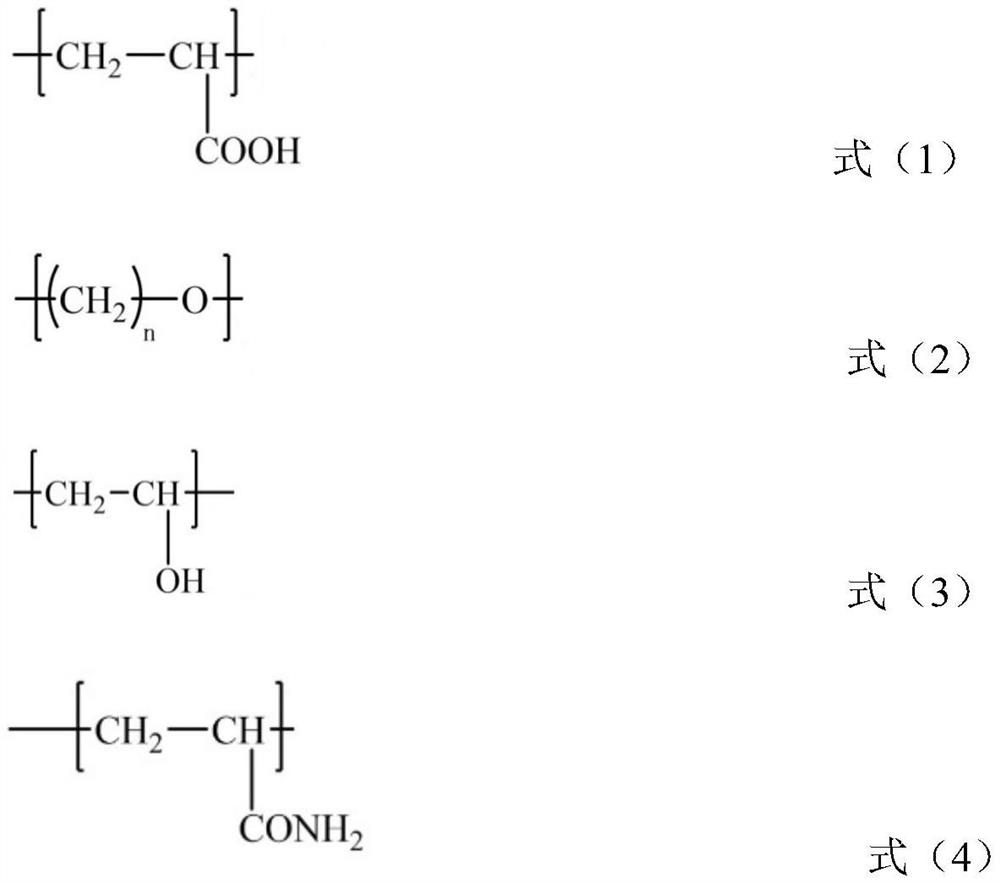

[0040] A surface coating agent for treating drilling solidified waste, comprising the following components in mass fraction: 30wt% acrylate polyether resin, 10wt% sodium silicate, 2wt% acetic acid, 25wt% vinyltrimethoxysilane , and the balance is water. The particle size of the coating agent is 120nm, and the viscosity at room temperature is 30mPa·s. Described acrylate polyether type resin contains the structural unit shown in formula (1)-formula (3), wherein, the mass ratio of the structural unit shown in formula (1), formula (2) and formula (3) is 3 :2:1, its weight average molecular weight is 40,000.

[0041]

[0042]

[0043] Among them, n=3.

[0044] Take 100g of drilling waste, solidify it with a curing agent containing cement-based cementitious material, and cure it under natural conditions for 14 days. After pre-treating the cured waste, brush one layer of coating agent, and after the coating agent dries to form a film, brush another layer in the same way. Af...

Embodiment 2

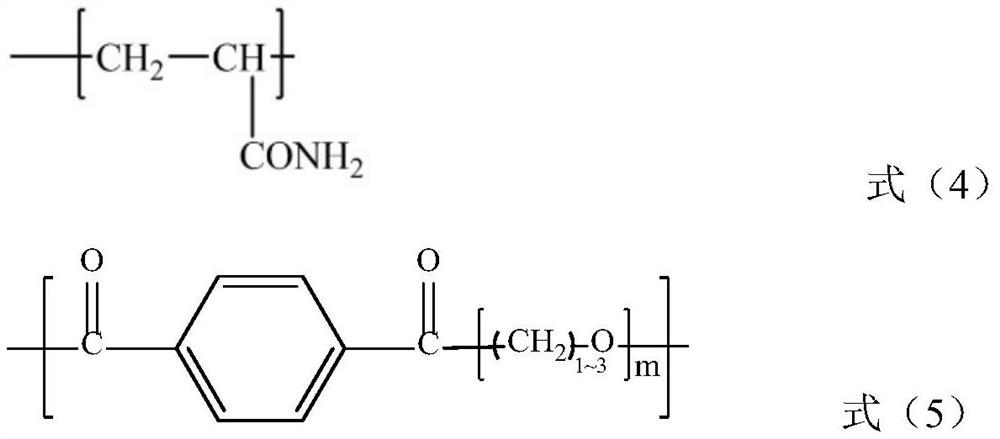

[0046] A surface coating agent for treating drilling solidified waste, comprising the following components in mass fraction: 30wt% acrylamide polyether type resin, 10wt% potassium silicate, 2wt% formic acid, 25wt% 3-glycidyl ether oxygen propyltriethoxysilane, and the balance is water. The particle size of the coating agent is 120nm, and the viscosity at room temperature is 30mPa·s. Described acrylamide polyether type resin contains the structural unit shown in formula (2), formula (3) and formula (4), wherein, the structural unit shown in formula (2) formula (3) and formula (4) The mass ratio is 3:2:5, and its weight average molecular weight is 50,000.

[0047]

[0048] Among them, n=2.

[0049] Take 100g of drilling waste, solidify it with a curing agent containing cement-based cementitious material, and cure it under natural conditions for 21 days. After pretreating and solidifying the waste, dip-coat one layer of coating agent, and after the coating agent dries to fo...

Embodiment 3

[0051] A kind of surface coating agent that is used for processing drilling solidification waste, comprises the component of following mass fraction: 30wt% terephthalate polyether type resin, 10wt% potassium silicate, 2wt% formic acid, 25wt% 3- Glycidyl etheroxypropyl triethoxysilane, the balance is water. The particle size of the coating agent is 120nm, and the viscosity at room temperature is 30mPa·s. The terephthalate polyether resin contains structural units represented by formula (5), and its weight average molecular weight is 80,000.

[0052]

[0053] Among them, m=15.

[0054] Take 100g of drilling waste, solidify it with a curing agent containing cement-based cementitious material, and cure it under natural conditions for 28 days. After the pretreatment of solidified waste, spray one layer of coating agent, and after the coating agent dries to form a film, spray another layer in the same way. After curing at a temperature of 40°C for 2 days, a surface-coated cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com