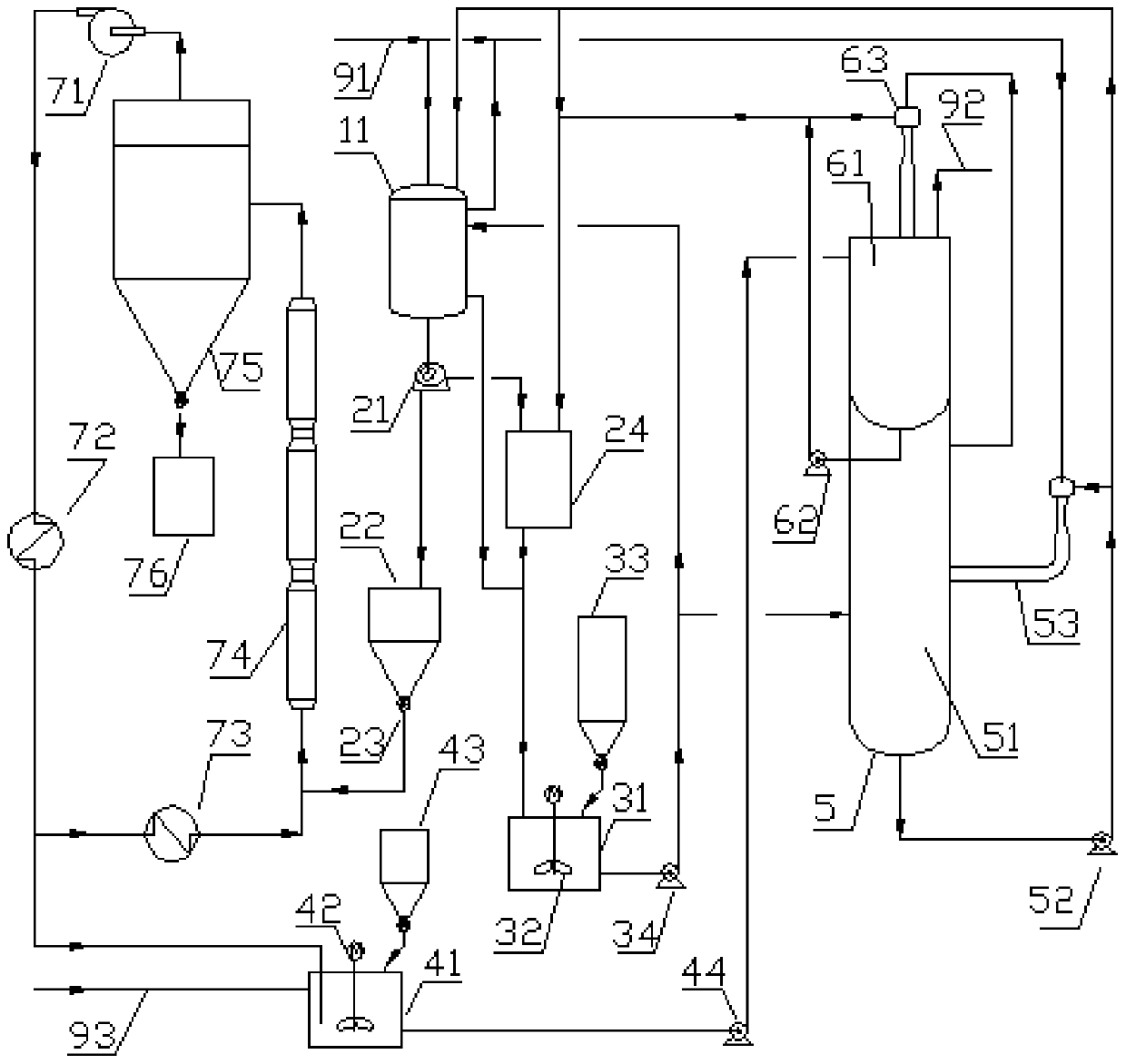

Device and method for preparing sulfite

A technology of sulfite and sodium sulfite, applied in the chemical industry, can solve the problems of high gas phase pressure loss, declining profit margin, high comprehensive energy consumption per unit of product, etc., and achieve the effect of small gas phase pressure loss and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] ①. Preparation of the main absorption liquid: when the device is running for the first time or after overhaul, use desalted water and soda ash in a concentrated alkali tank to prepare a thick slurry with a temperature of 45-57°C and a relative density of 1.28-1.35; after normal production, Using the mother liquor of saturated sodium bisulfite as a solvent and soda ash as a solute, prepare a thick slurry with a temperature of 42-57°C and a relative density of 1.45-1.55 in a concentrated alkali tank;

[0053] ②. Preparation of auxiliary absorption liquid: use desalted water and condensed water condensed from the drying system to dissolve soda ash, and prepare dilute alkali solution with a temperature of 42-57°C and a relative density of 1.25-1.33 in a dilute alkali tank;

[0054] ③. Generation of intermediate slurry: transfer the prepared slurry in step ① to the first stage reactor of the tower reactor through the concentrated alkali pump, and carry out countercurrent cont...

Embodiment 2

[0060] ①. The preparation of the main absorption liquid: with example 1.

[0061] ②. Preparation of auxiliary absorption liquid: same as Example 1.

[0062] ③. Generation of intermediate slurry: transfer the slurry prepared in step ① to the first stage of the tower reactor through the concentrated alkali pump, and mix with SO 2 The raw material gas is subjected to a countercurrent contact reaction to generate an intermediate slurry of sodium sulfite and sodium bisulfite;

[0063] ④. Residual SO 2 Gas reabsorption: transfer the dilute slurry prepared in step ② to the second-stage reactor of the tower reactor through the dilute alkali pump, react with the residual gas from the first-stage reactor (51), and transfer the first-stage reaction After the reactor (51) the SO in the residual gas The volume concentration drops below 0.1%. After the pH value of the absorption liquid in the second stage reactor 61 drops to 6.8~7.8, it is transferred to the mother liquor tank 24 by the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com