Composite nanofiltration membrane for highly-efficient separation of monovalent and divalent salts

A composite nanofiltration membrane and divalent salt technology, applied in semi-permeable membrane separation, membrane technology, water/sludge/sewage treatment, etc., can solve the problems of inability to meet application requirements, low performance, etc., to improve anti-fouling ability , The effect of reducing energy consumption and high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0034] Adding nanometer material and surfactant alkylphenol polyoxyethyl ester phosphate into N-methylpyrrolidone (NMP) organic solvent, ultrasonication, stirring and dispersing to form a uniform suspension.

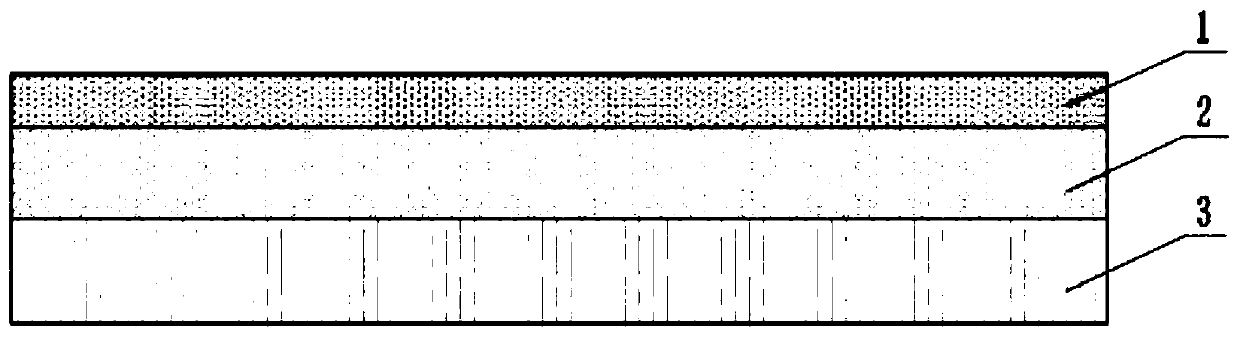

[0035] The base membrane material polysulfone and cellulose are gradually added to the above suspension under stirring, wherein polysulfone, NMP and cellulose are made according to the mixing ratio of 65:25:10, and the inorganic porogen lithium nitrate or chlorine is added Sodium chloride, magnetically stirred for 24 hours to form a uniform casting solution, filtered with a 100-mesh non-woven fabric in an environment with a humidity lower than 40%, and then ultrasonic-vacuum filtration repeated 3 times for degassing. Cast the defoamed casting solution onto a PET (polyester---polyethylene terephthalate) woven cloth with a thickness of 5mil as a support material to form the primary ecology of a uniformly porous base film flat film, or through spinning Sheets are extruded i...

Embodiment 4-8

[0043] As in the previous examples, according to the above method, add the nanomaterials and polyoxyethyl phenol phosphate into the organic solvent, and disperse by ultrasonication and stirring to form a uniform suspension. The base film material polysulfone and cellulose are gradually added into the suspension under stirring, wherein the polysulfone, organic solvent and cellulose are made according to different mixing ratios.

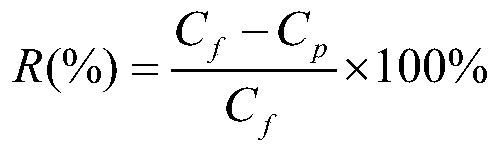

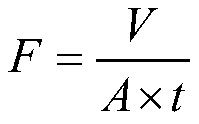

[0044] The prepared composite nanofiltration membrane was tested with 500mg / l sodium chloride aqueous solution and sodium sulfate aqueous solution at 1.0MPa, 25°C and pH6.8 to test the solute removal rate and water flux of the membrane.

[0045] These several examples are to investigate the influence of the type of organic solvent on the performance of the composite nanofiltration membrane, and the results are shown in Table 2.

[0046]

[0047] As can be seen from the above table, the addition of nanomaterials and alkylphenol polyoxyethyl ester pho...

Embodiment 9-12

[0049]As in the previous examples, according to the above method, add nanomaterials and surfactant alkylphenol polyoxyethyl ester phosphate into N-methylpyrrolidone (NMP) organic solvent, ultrasonically, stir and disperse to form a uniform suspension. The base membrane material polysulfone and cellulose are gradually added into the suspension under stirring, wherein polysulfone, NMP and cellulose are made according to different mixing ratios.

[0050] The prepared composite nanofiltration membrane was tested with 500mg / l sodium chloride aqueous solution and sodium sulfate aqueous solution at 1.0MPa, 25°C and pH6.8 to test the solute removal rate and water flux of the membrane.

[0051] These several examples are to investigate the effect of the mixing ratio of polysulfone, NMP and cellulose on the performance of the composite nanofiltration membrane, and the results are shown in Table 3.

[0052]

[0053] It can be seen from the above table that the mixing ratio of polysulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com