Power battery box body, preparation method thereof and fiber reinforced composite material

A power battery and box technology, applied in the field of power battery boxes, can solve problems such as complexity and multiple layers, and achieve the effects of lower price, high safety and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

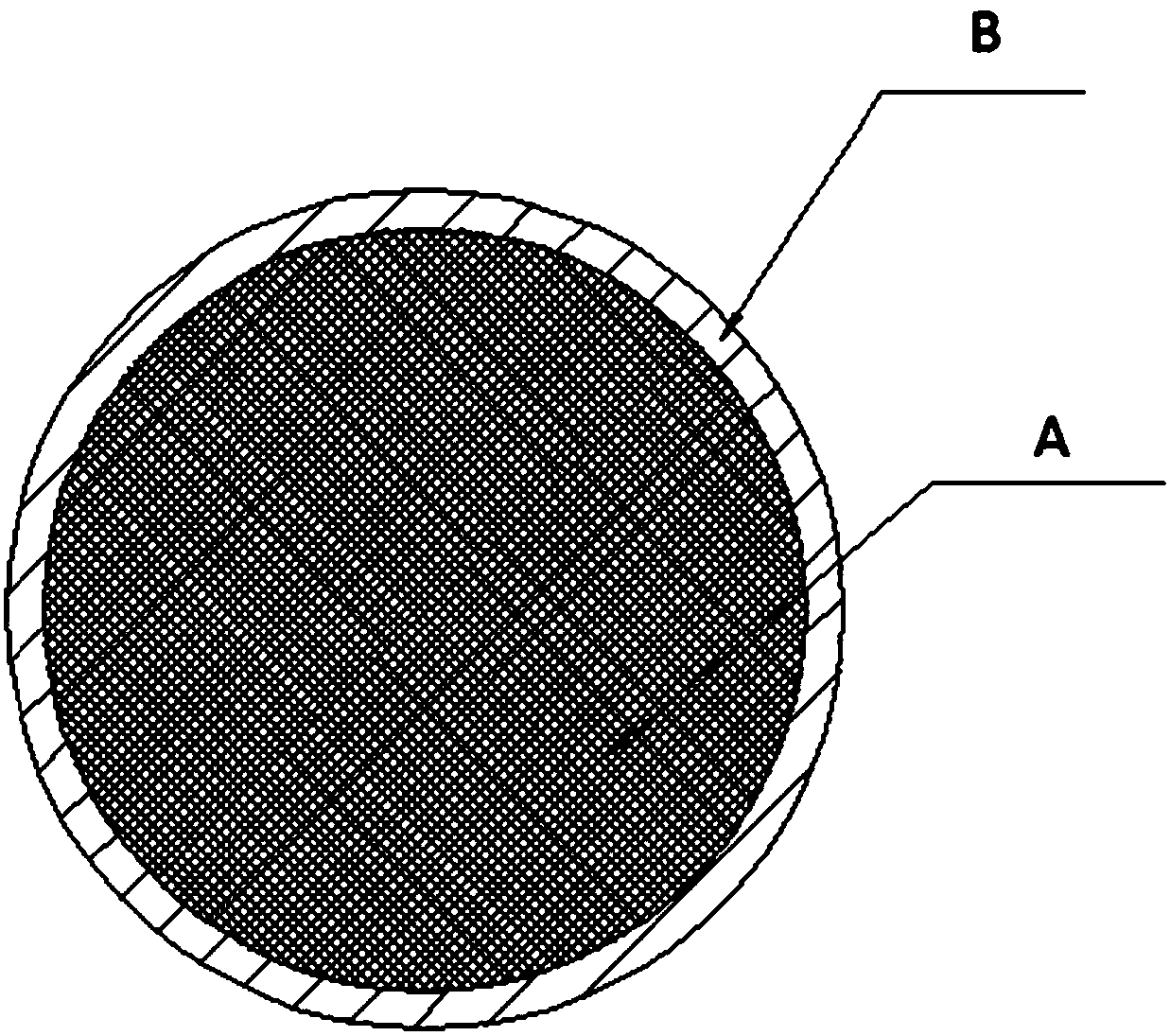

[0064] The fiber-reinforced composite material used in the battery box of this embodiment is mainly made of the following raw materials in parts by weight: 50 parts of polymer matrix material, 30 parts of metal-plated fiber, 10 parts of lubricant, 40 parts of flame retardant, filler 2 parts of anti-oxidant, 0.05 parts of antioxidant, and 10 parts of curing agent; the polymer matrix material used is unsaturated polyester resin, the metal-plated fiber is nickel-plated glass fiber with a length of no more than 2.5mm, and the lubricant is paraffin oil. The flame retardant is a phosphorus-nitrogen series halogen-free intumescent flame retardant, the filler is talcum powder, the antioxidant is zinc stearate, and the curing agent is styrene.

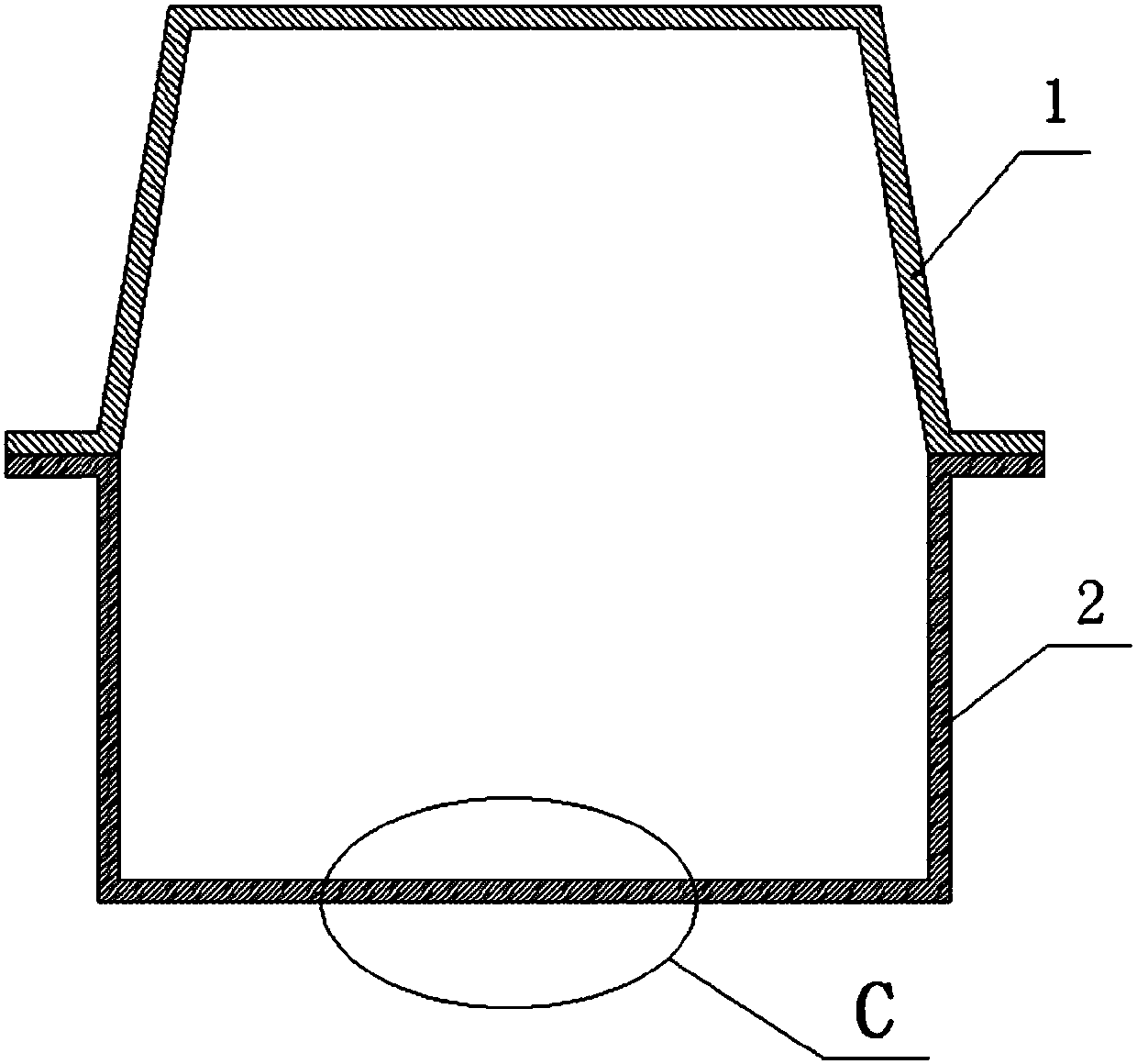

[0065] The power battery case of this embodiment, such as figure 2 As shown, the upper box cover 1 and the lower box body 2 including the sealing fit are mainly made of the following raw materials in parts by weight: 50 parts of polymer matrix...

Embodiment 2

[0068] The fiber-reinforced composite material of this embodiment is mainly made of the following raw materials in parts by weight: 65 parts of polymer matrix material, 30 parts of reinforcing fiber, 5 parts of lubricant, 45 parts of flame retardant, 1 part of filler, antioxidant 0.5 parts of curing agent and 5 parts of curing agent; the polymer base material used is unsaturated polyester resin, the metal-plated fiber is nickel-plated continuous basalt fiber (the length is determined according to the size of the box), and the lubricant is paraffin oil. The flame retardant is phosphorus nitrogen-based halogen-free intumescent flame retardant, the filler is talcum powder, the antioxidant is barium stearate, and the curing agent is styrene.

[0069] The power battery case of this embodiment, including the upper case cover and the lower case body that are sealed and fitted, is mainly made of the following raw materials in parts by weight: 65 parts of polymer matrix material, 30 par...

Embodiment 3

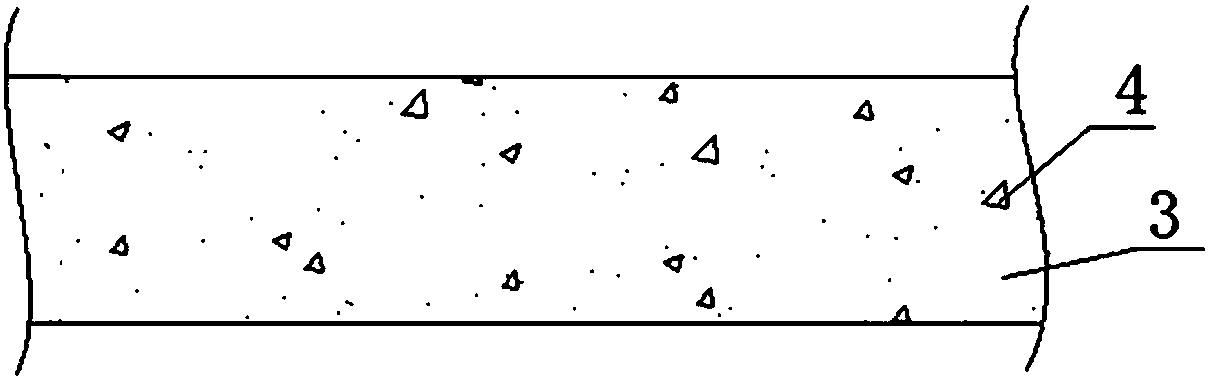

[0072] The fiber-reinforced composite material of this embodiment is mainly made of the following raw materials in parts by weight: 45 parts of polymer matrix material, 45 parts of metal-plated fiber fabric, 8 parts of lubricant, 35 parts of flame retardant, 1.5 parts of filler, 0.05 parts of antioxidant, 7 parts of curing agent; the polymer base material used is glycidyl amine epoxy resin, the metal-coated fiber fabric is aluminized carbon fiber T700 cloth, the lubricant is paraffin oil, and the flame retardant is phosphorus nitrogen It is a halogen-free intumescent flame retardant, the filler is talcum powder, the antioxidant is zinc stearate, and the curing agent is ethylenediamine.

[0073] The power battery case of this embodiment, such as Figure 4 As shown, the upper box cover 5 and the lower box body 6 including the sealing fit are mainly made of the following raw materials in parts by weight: 45 parts of polymer matrix material, 45 parts of metal-plated fiber fabric, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com