Amino-carbonate hydroxyapatite composite material, and preparation method and application thereof

A technology of aminocarbohydroxyapatite and carboxyapatite, which is applied in the field of environmental pollution control and can solve the problems of low adsorption capacity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The present invention also provides a method for preparing the aminocarbon hydroxyapatite composite material described in the above technical solution, comprising the following steps:

[0071] Mixing hydroxyapatite, a silane coupling agent and a solvent to perform a modification reaction to obtain modified hydroxyapatite;

[0072] Mix the modified carbohydroxyapatite, 4-[N,N-bis(2-pyridylmethyl)amino-1,8-naphthalene dicarboxylic anhydride] and solvent, and carry out grafting reaction to obtain amino carbohydroxyl Apatite composite.

[0073] The invention mixes the carbohydroxyapatite, the silane coupling agent and the solvent to carry out the modification reaction to obtain the modified carbohydroxyapatite.

[0074] In the present invention, the mixing is preferably performed in a round bottom flask. The present invention has no special limitation on the mixing method, and a conventional mixing method by those skilled in the art can be used. In the present invention,...

Embodiment 1

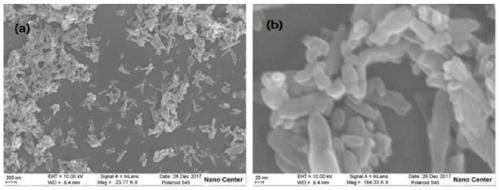

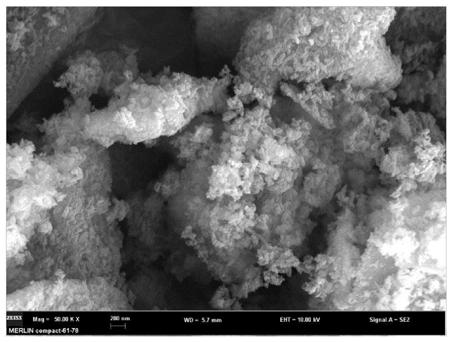

[0083] Preparation of carbohydroxyapatite (CHAP)

[0084] 1) Weigh 12g of discarded eggshells after washing and drying, put them into 50mL acetic acid solution with a mass concentration of 12%, remove the inner membrane of the eggshells at 40°C, wash with distilled water until neutral, and dry , crushed into powder, calcined at 470°C for 3.5 hours to remove organic matter, and passed through a 40-mesh sieve;

[0085] 2) Weigh 12g of the eggshell powder obtained in step 1), and put it into H at a molar ratio of 1:1 3 PO 4 In the solution, use hydrochloric acid and sodium hydroxide to adjust the pH value of the system to 3.0, place it in an ultrasonic generator with an ultrasonic frequency of 150 Hz, and react for 2.5 hours at 40°C to prepare the transition state calcium hydrogen phosphate;

[0086] 3) Weigh 4g of urea and mix it with 20mL of distilled water to obtain a urea solution;

[0087] 4) Weigh 5g molten Ca(OH) 2 , and use ammonia water to adjust the pH value of the ...

Embodiment 2

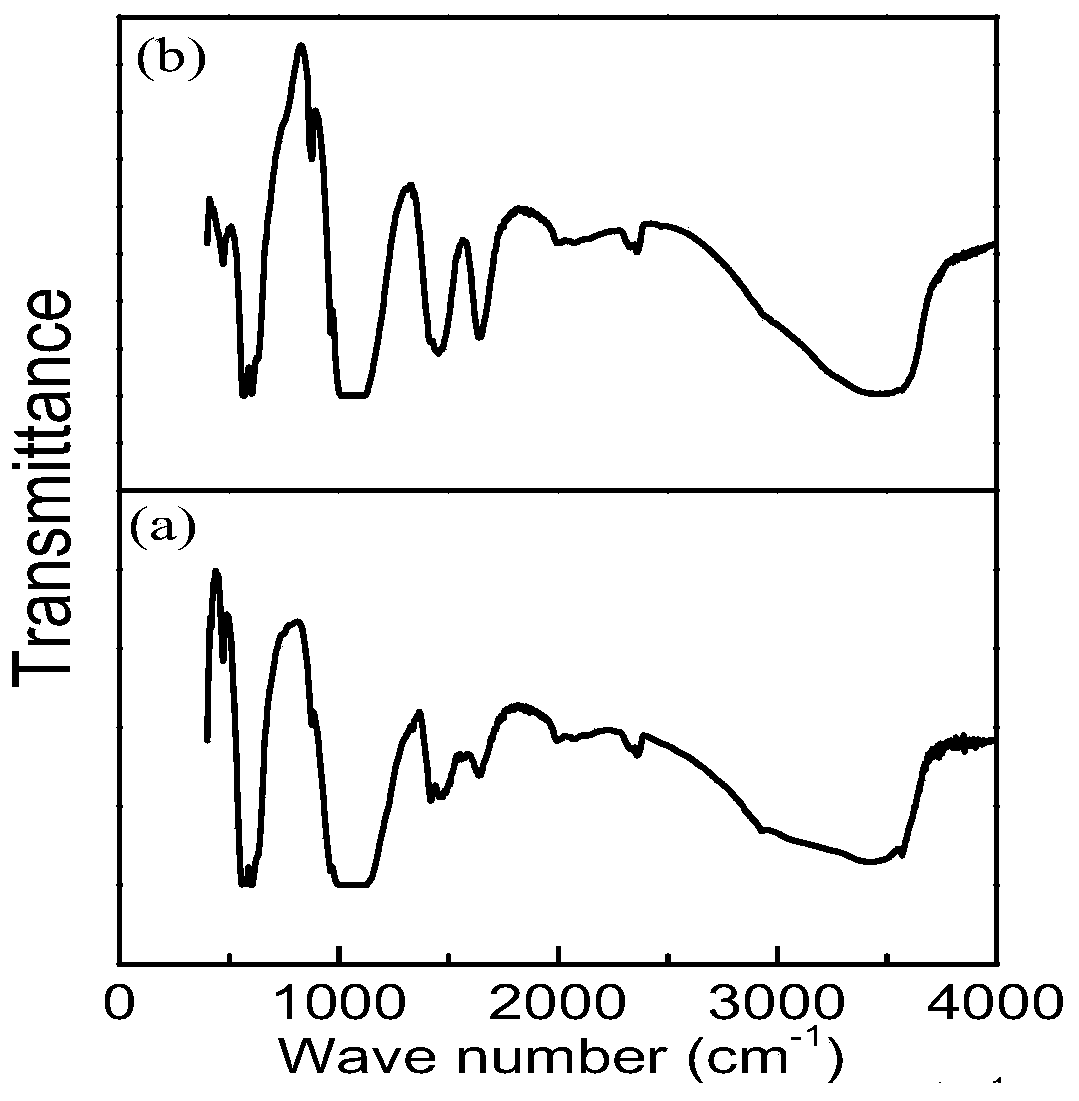

[0110] Weigh 10 parts of 0.06g CHAP-NH prepared in Example 1 2 , respectively for the treatment of Cu-containing 2+ Ionic solution 100L, Cu in the solution 2+ The initial concentration of ions is 150mg / L, the temperature is 40°C, and the adsorption time is 50min.

[0111] Figure 6 Cu 2+ The pH value of the ionic solution on the CHAP-NH 2 Adsorbed Cu 2+ The influence diagram of the ion effect, it can be seen from the figure that when the pH value of the solution is low, CHAP-NH 2 to Cu 2+ The adsorption rate of ions is relatively low. When the pH value of the solution is 1.5≤pH≤5.0, CHAP-NH 2 to Cu 2+ The adsorption rate of ions increases with the increase of the pH value of the solution, respectively rising rapidly from 62% to 96%; when the pH value of the solution increases to 6.5, CHAP-NH 2 to Cu 2+ The adsorption rate of ions remained basically unchanged. The reason may be that under the condition of low pH value of the solution, the H in the solution + The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com