Nitrogen-phosphorus intumescent flame retardant and its preparation method for application in waterborne polyurethane coatings

A nitrogen-phosphorus intumescent, water-based polyurethane technology is used in the preparation of nitrogen-phosphorus intumescent flame retardants, and in the field of nitrogen-phosphorus intumescent flame retardants for preparing water-based polyurethane coatings, which can solve the problems of poor compatibility, safety hazards, and easy generation of molten droplets. and other problems, to achieve the effect of improving flame retardancy, improving flame retardancy and maintaining original properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

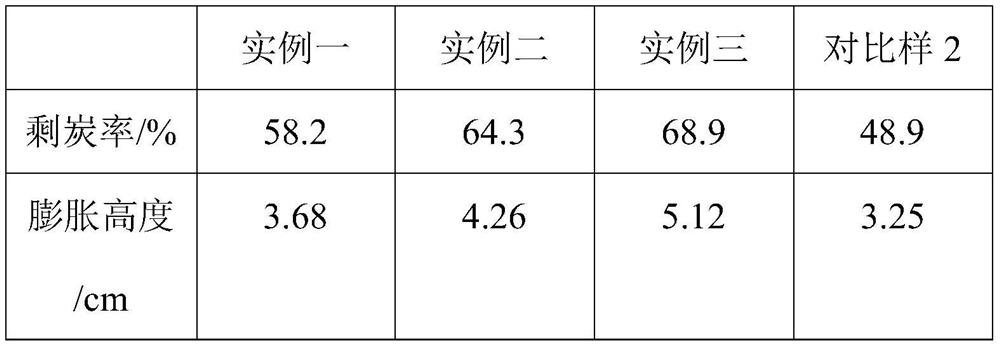

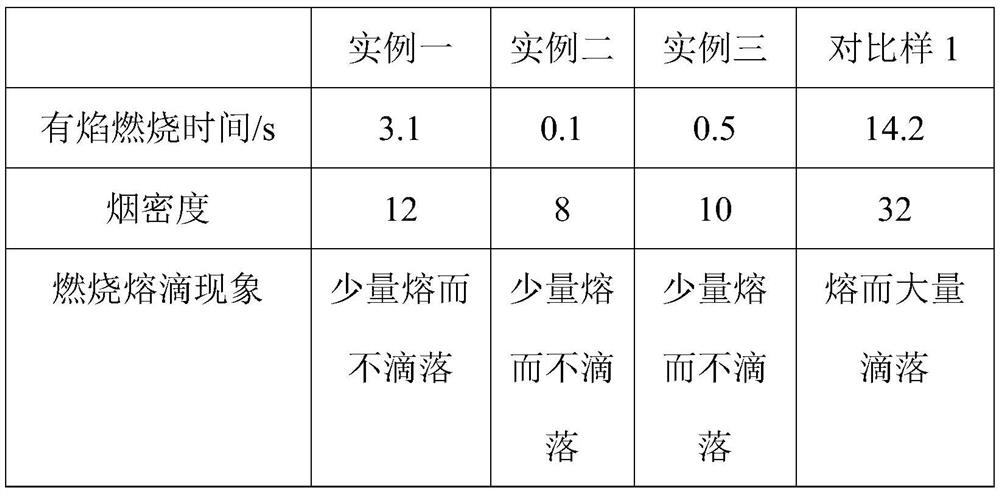

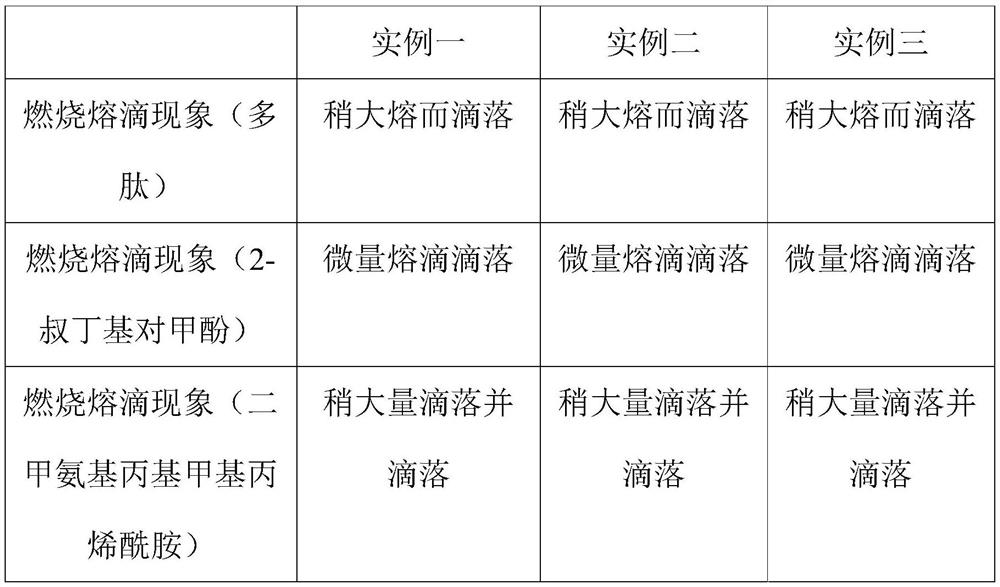

Examples

example 1

[0038](1) Preparation of nitrogen-phosphorus intumescent flame retardant: add 1 mol of dimethyl phosphite, add alkaline catalyst sodium methoxide to 1 / 10 of the weight of dimethyl phosphite, then add 0.9 mol of acrylamide, the reaction temperature is 70 React at ℃ for 3 hours to obtain 3-dimethoxyphosphoryl propionamide, which is intermediate A. Lower the temperature of the intermediate product to 50℃, add 0.9 mol of trimethylchlorosilane and 0.1 mol of potassium sodium tartrate, and stir at 60℃. React for 2h, adjust the pH of the solution with sodium hydroxide during the stirring process to stabilize the pH of the solution at 6.5-7.0, then add 3.1g of 2,4-dihydroxybenzophenone and 0.2g of 1,3,5-triazine, Stir the reaction at 60°C for 2 hours, and concentrate until the solid content reaches 90% (not exceeding 92%) to obtain the nitrogen-phosphorus intumescent flame retardant.

[0039](2) In a 500ml three-necked flask equipped with a stirring blade, a thermometer and a condenser, add 45...

example 2

[0043](1) Preparation of nitrogen-phosphorus intumescent flame retardant: add 1 mol of dimethyl phosphite, add alkaline catalyst sodium methoxide to 1 / 10 of the weight of dimethyl phosphite, then add 1.2 mol of acrylamide, reaction temperature 90 React at ℃ for 5 hours to obtain 3-dimethoxyphosphoryl propionamide, which is intermediate A. Lower the temperature of the intermediate product to 55℃, add 1.3 mol of cyanuric chloride and 0.1 mol of sodium nitrilotriacetate, and stir at 80℃ React for 5h, adjust the pH of the solution with sodium hydroxide during the stirring process to stabilize the pH of the solution at 6.5-7.0, then add 8.7g of itaconic anhydride and 0.4g of indole-3-acetamide, stir and react at 80℃ for 5h, It is concentrated to a solid content of 90% (not exceeding 92%) to obtain the nitrogen-phosphorus intumescent flame retardant.

[0044](2) In a 500ml three-necked flask equipped with a stirring blade, a thermometer and a condenser, add 45g of hexanediol, 24.8g of hexame...

example 3

[0047](1) Preparation of nitrogen-phosphorus intumescent flame retardant: add 1 mol of dimethyl phosphite, add alkaline catalyst sodium methoxide to 1 / 10 of the weight of dimethyl phosphite, then add 1.05 mol of acrylamide, and the reaction temperature is 80 React at ℃ for 4 hours to obtain 3-dimethoxyphosphoryl propionamide, which is intermediate A. The temperature of the intermediate product is reduced to 50℃, and 1.1 mol of trimethylolpropane and 0.1 mol of p-nitrobenzoic acid are added at 70℃. Stir the reaction for 3.5 hours, adjust the pH of the solution with sodium hydroxide during the stirring process to stabilize the pH of the solution at 6.5-7.0, then add 5.9 g of citraconic acid and 0.3 g of dimethyl 1,4-cyclohexanedicarboxylate, Stir and react for 3.5 hours at 70°C, and concentrate until the solid content reaches 90% (not more than 92%) to obtain the nitrogen-phosphorus intumescent flame retardant.

[0048](2) In a 500ml three-necked flask equipped with a stirring blade, a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com