Manufacturing method of light wallboard with glaze

A light-weight wallboard, technology of manufacturing method, applied in the direction of walls, clay products, ceramic products, etc., can solve problems such as prone to serious fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

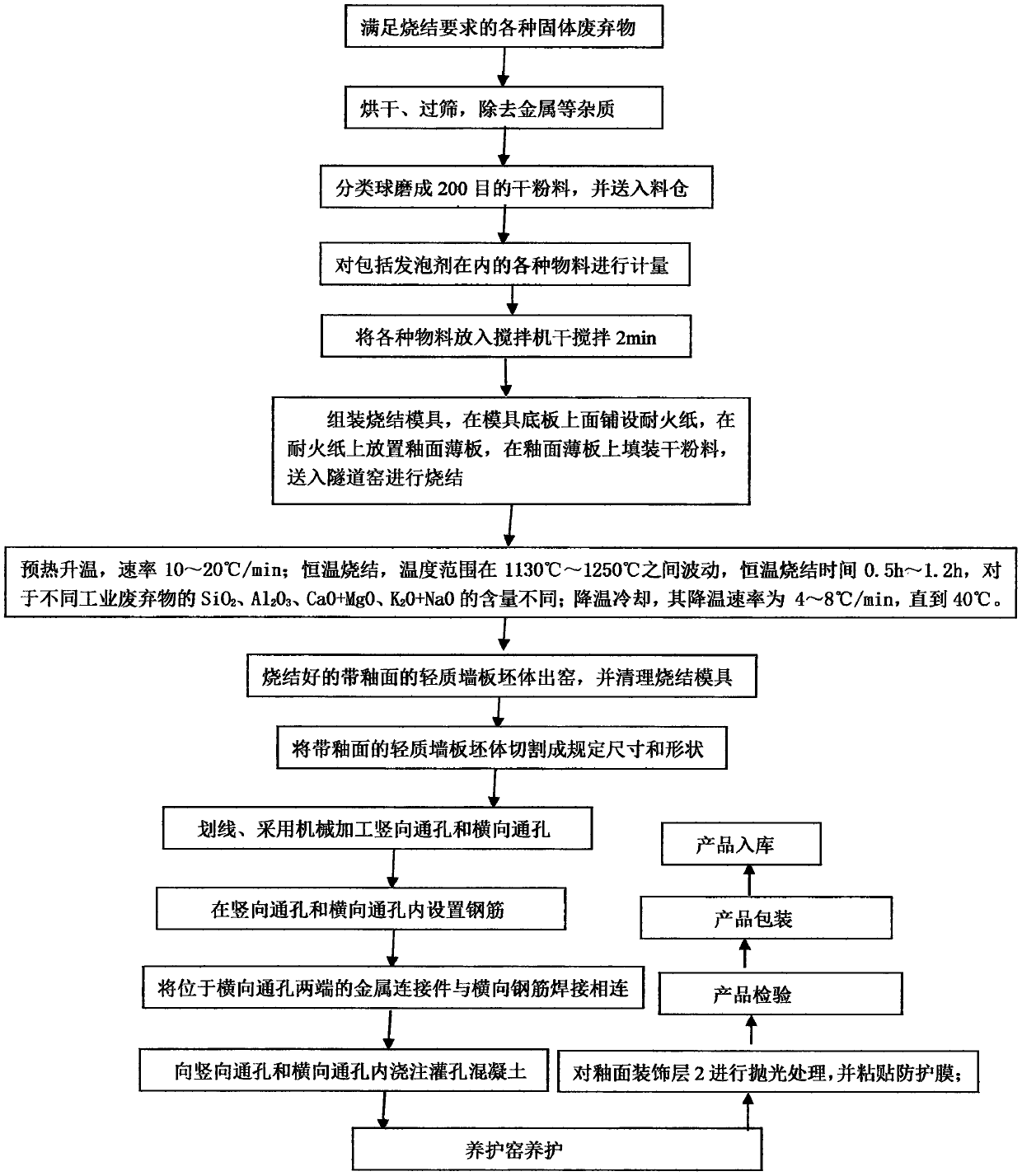

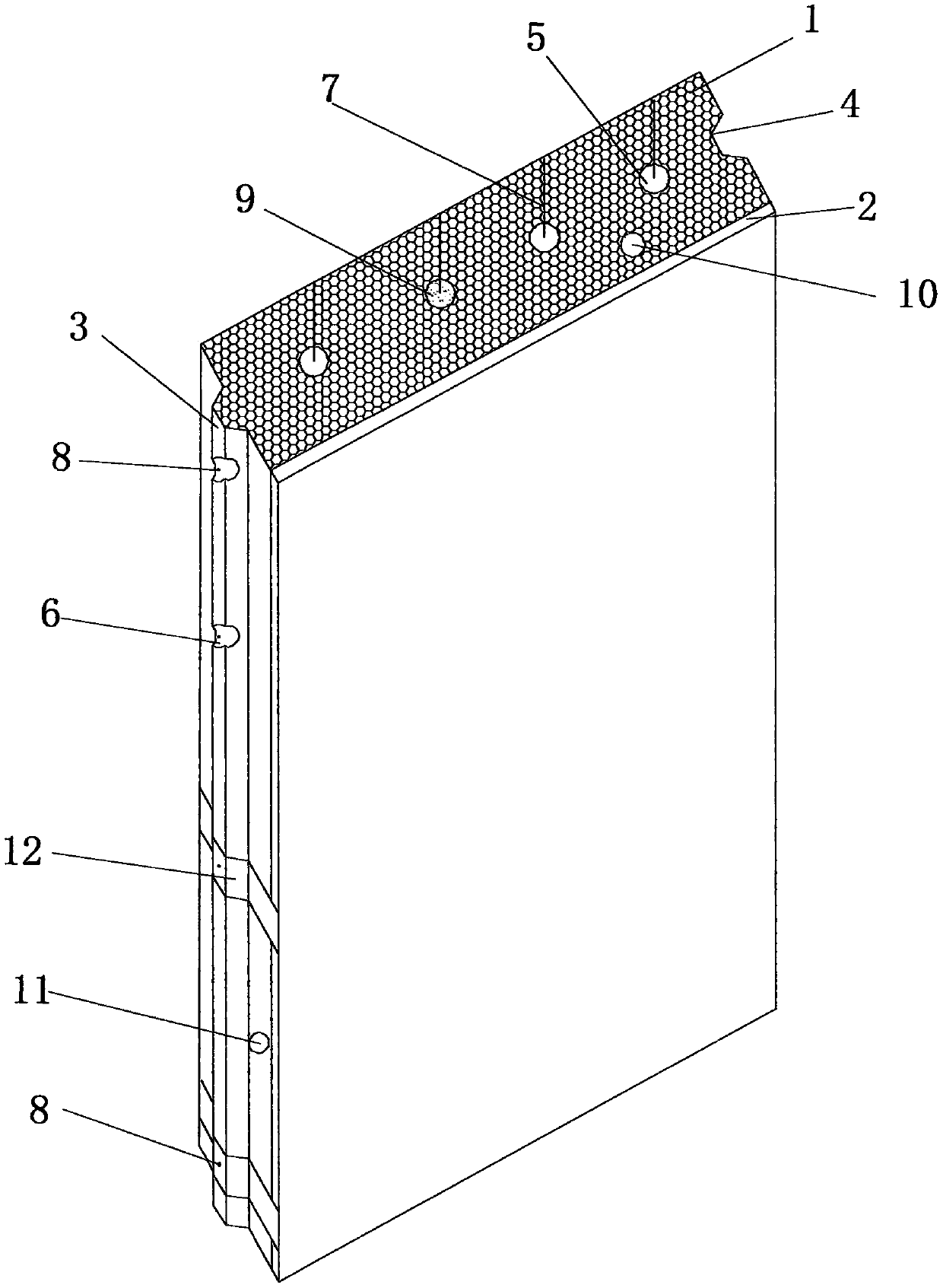

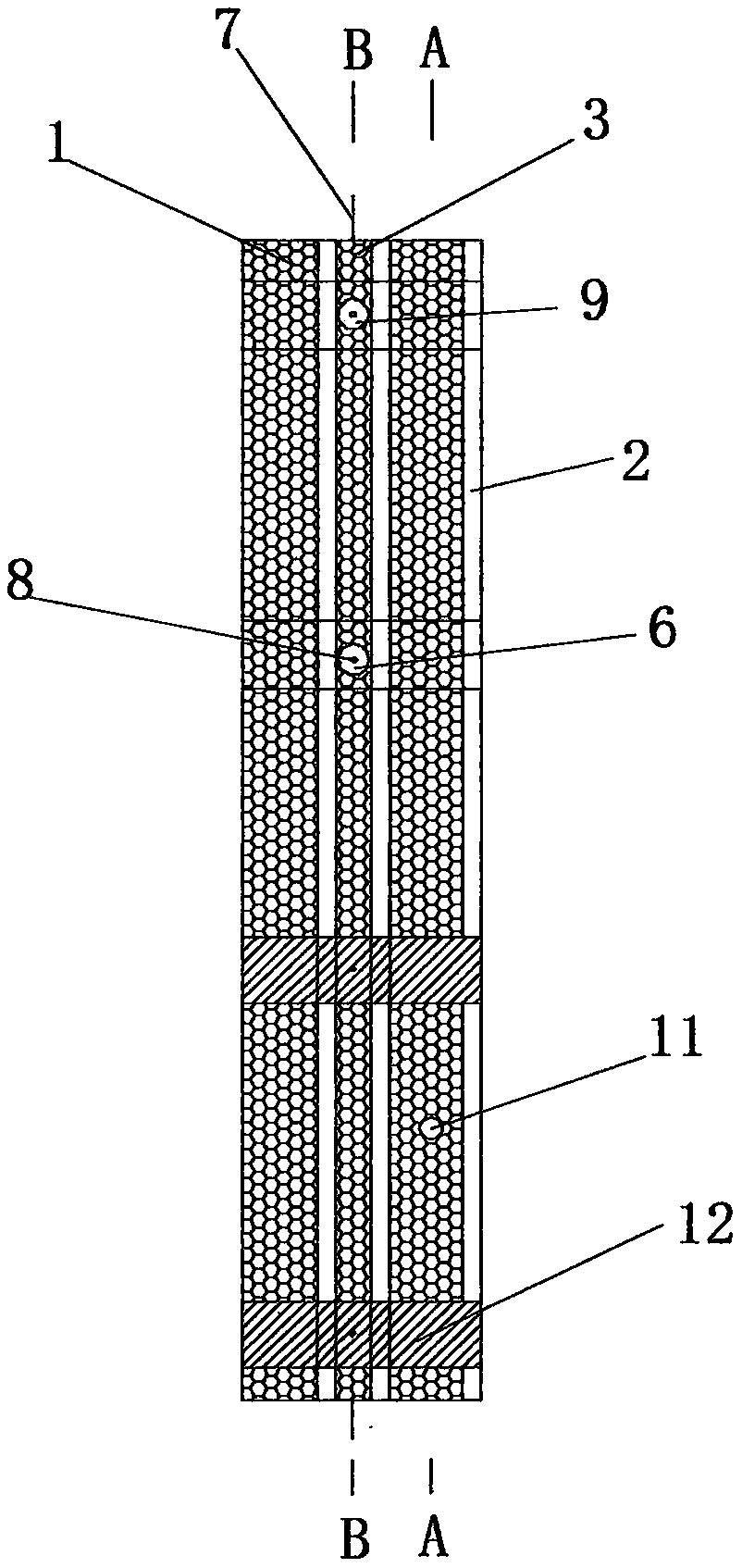

[0050] The present invention is achieved like this, below in conjunction with appendix Figure 1 to Figure 8 For further explanation: a kind of manufacture method of the light-weight wallboard with glaze, comprises the following steps:

[0051] 1) Dry tailings powder, construction waste, fly ash, waste molding sand and other wastes that meet the requirements of the sintered lightweight wallboard substrate 1, and then sieve to remove impurities such as metals;

[0052] 2) The sieved solid waste is ball milled according to different types, and the fineness of the dry powder is 200 mesh, and it is sent to the dry powder storage for standby;

[0053] 3) The required materials including foaming agent will be measured according to the ratio;

[0054] 4) Send the measured material into the mixer for mixing and dry mixing for 2 minutes;

[0055] 5) Assemble the sintering mold, lay fire-resistant paper on the bottom plate of the mold, place a glazed sheet on the fire-resistant paper,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com