A kind of core-shell structure nanocomposite material based on biological method and its preparation method

A nanocomposite material and composite material technology, which can be used in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., and can solve the problems of poor dispersion, interfaciality and stability, etc. Achieve the effect of narrow particle size distribution, high stability and improved mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

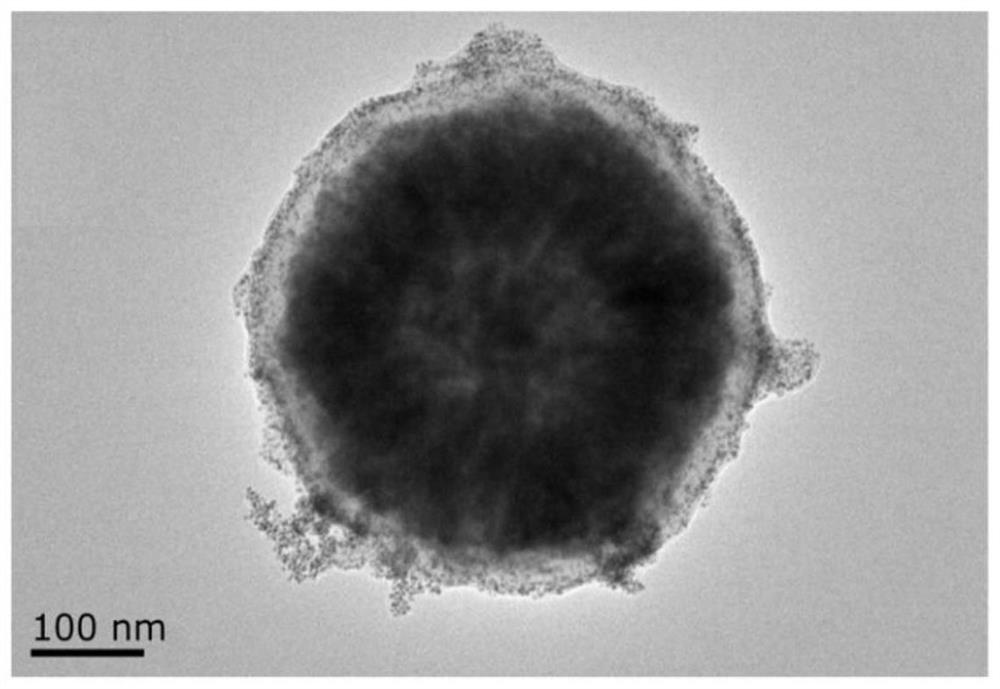

Image

Examples

Embodiment 1

[0030] At room temperature, weigh 0.6g glycine and ultrasonically disperse in 30mL ethanol for 15min, then add 0.03mol ethylenediaminetetraacetic acid, stir for 1h, then add 1.0mL titanium n-butoxide, and continue stirring for 1h, finally transfer to 50mL polytetrafluoroethylene In an ethylene-lined hydrothermal reactor, hydrothermally react at 200°C for 20h, wash with ethanol, and dry at 60°C for 12h to obtain mesoporous TiO 2 hollow nanospheres;

[0031] Weigh 2g of Cinnamomum camphora leaf dry powder and ultrasonically disperse it in 100mL of deionized water for 15min, then heat at 90°C for 15min, cool and filter with suction to obtain the filtrate of plant matter extract with a concentration of 20g / L. Weigh 0.1 g of mesoporous TiO prepared in step a) 2 Hollow nanospheres were immersed in 5mL of chloroauric acid (concentration: 1mg / mL) for 1h, then 20mL of cinnamon camphor leaf extract was added, stirred for 2h, centrifuged with deionized water, dried at 60°C for 12h to ob...

Embodiment 2

[0036] At room temperature, weigh 0.8g alanine and ultrasonically disperse it in 40mL ethanol for 20min, then add 0.04mol sodium citrate, stir for 2h, then add 0.5mL titanium isopropoxide, and continue stirring for 0.5h, finally transfer to 50mL polytetrafluoroethylene In a vinyl fluoride-lined hydrothermal reaction kettle, hydrothermally react at 250°C for 18h, wash with ethanol, and dry at 50°C for 12h to obtain mesoporous TiO 2 hollow nanospheres;

[0037] Weigh 3g of Cinnamomum camphora leaf dry powder and ultrasonically disperse it in 100mL of deionized water for 20min, then heat at 80°C for 20min, cool and filter with suction to obtain the filtrate of plant matter extract with a concentration of 30g / L. Weigh 0.2g of mesoporous TiO prepared in step a) 2 The hollow nanospheres were immersed in 5 mL of gold acetate (concentration: 0.5 mg / mL) for 2 h, then 15 mL of cinnamomum camphora leaf extract was added, stirred for 3 h, washed with deionized water, and dried at 50 °C f...

Embodiment 3

[0042] At room temperature, weigh 0.7g leucine and ultrasonically disperse it in 30mL ethanol for 10min, then add 0.05mol sodium tartrate, stir for 3h, then add 1.5mL titanium n-butoxide, and continue stirring for 2h, finally transfer to 50mL polytetrafluoroethylene In the lined hydrothermal reaction kettle, hydrothermal reaction was carried out at 200 °C for 30 h, centrifuged and washed with ethanol, and dried at 80 °C for 10 h to obtain mesoporous TiO 2 hollow nanospheres;

[0043] Weigh 1g of dry powder of camphor leaves and ultrasonically disperse in 100mL of deionized water for 10min, then heat at 80°C for 10min, cool and filter with suction to obtain a filtrate of plant matter extract with a concentration of 10g / L. Weigh 0.1 g of mesoporous TiO prepared in step a) 2 The hollow nanospheres were immersed in 5 mL of gold acetate (concentration: 0.2 mg / mL) for 0.5 h, then 30 mL of camphor leaf extract was added, stirred for 2 h, washed with deionized water, and dried at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com