Purification method of heavy metal contaminated soil

A technology for polluted soil and heavy metals, applied in the field of purification of heavy metal-contaminated soil, can solve problems such as remediation effect and socio-economic feasibility to be verified, bioremediation is slow, and soil functions are damaged, so as to reduce the risk of secondary pollution of heavy metals, Inexpensive raw materials, the effect of promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

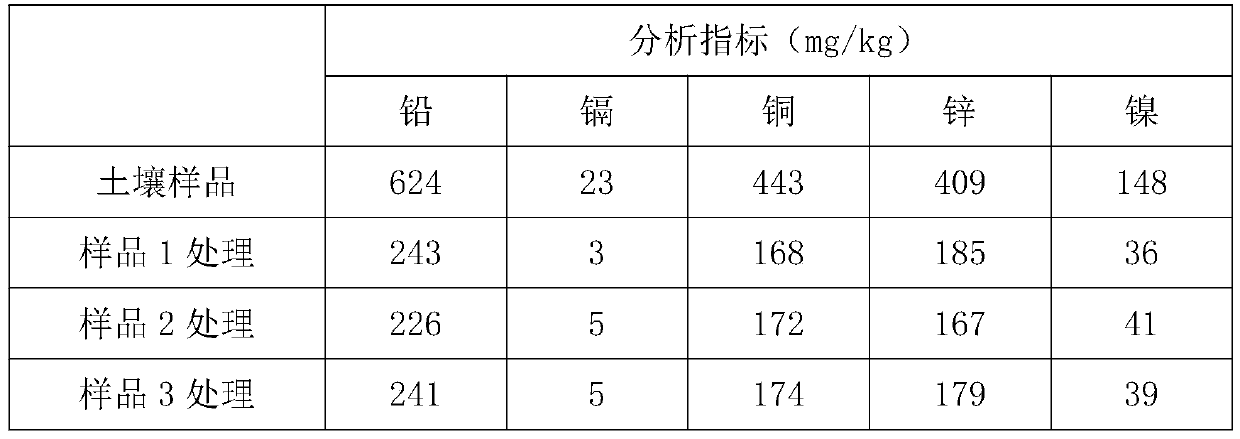

Examples

Embodiment 1

[0022] A method for purifying heavy metal contaminated soil, comprising the following steps:

[0023] (1) 60 kg of biochar and 20 kg of bentonite were crushed through an 80-mesh sieve, and then mixed with 1 kg of rhamnolipid, 5 kg of composite bacterial agent, and 4 kg of heavy metal trapping agent to obtain heavy metal repair material sample 1;

[0024] (2) Plow the contaminated soil to a depth of 70 cm, spread a layer of repair material therein, cover the soil to a depth of 25 cm, and then lay a layer of repair material, and the thickness of each layer of repair material is 3 cm;

[0025] (3) Regularly detect the heavy metal content in the soil;

[0026] (4) After the heavy metal content in the soil is stabilized, recover the restoration materials from the soil.

[0027] The preparation method of the biochar is as follows: the plant stalks are chopped and put into a calciner, heated to 400° C., kept for calcination for 3 hours, then cooled naturally, and the biochar is coll...

Embodiment 2

[0032] A method for purifying heavy metal contaminated soil, comprising the following steps:

[0033] (1) 65kg of biochar and 17kg of bentonite were crushed through a 60-mesh sieve respectively, and then mixed with 1kg of rhamnolipid, 3kg of composite bacterial agent, and 2kg of heavy metal trapping agent to obtain heavy metal restoration material sample 2;

[0034] (2) Plow the polluted soil to a depth of 60 cm, spread a layer of repair material into it, cover the soil to a depth of 20 cm, and then spread a layer of repair material, and the thickness of each layer of repair material is 2 cm;

[0035] (3) Regularly detect the heavy metal content in the soil;

[0036] (4) After the heavy metal content in the soil is stabilized, recover the restoration materials from the soil.

[0037] The preparation method of the biochar is as follows: the plant stalks are chopped and put into a calciner, heated to 350° C., kept for 2 hours and then cooled naturally, and the biochar is collec...

Embodiment 3

[0042] A method for purifying heavy metal contaminated soil, comprising the following steps:

[0043] (1) 75kg of biochar and 23kg of bentonite were crushed through a 100-mesh sieve respectively, and then mixed with 2kg of rhamnolipid, 8kg of composite bacterial agent, and 5kg of heavy metal trapping agent to obtain heavy metal restoration material sample 3;

[0044] (2) Plow the contaminated soil to a depth of 80 cm, spread a layer of repair material into it, cover the soil to a depth of 30 cm, and then lay a layer of repair material, and the thickness of each layer of repair material is 4 cm;

[0045] (3) Regularly detect the heavy metal content in the soil;

[0046] (4) After the heavy metal content in the soil is stabilized, recover the restoration materials from the soil.

[0047] The preparation method of the biochar is as follows: the plant stalks are chopped and put into a calciner, heated to 450° C., kept for 4 hours and then cooled naturally, and the biochar is coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com