Preparation method of composite material based on modified graphene oxide

A composite material and technology of oxide stone, which is applied in the field of composite material preparation based on modified graphene oxide, can solve problems such as poor compatibility, unfavorable performance of composite materials, weak interface bonding, etc., and achieve strong interface bonding force and excellent preparation method Simple and efficient, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

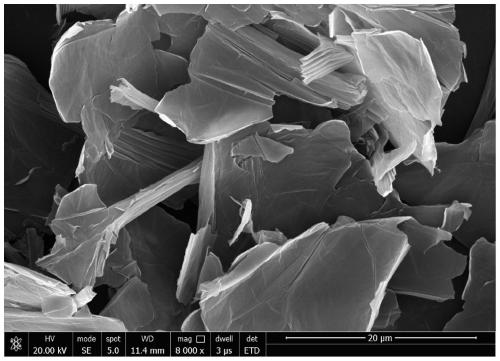

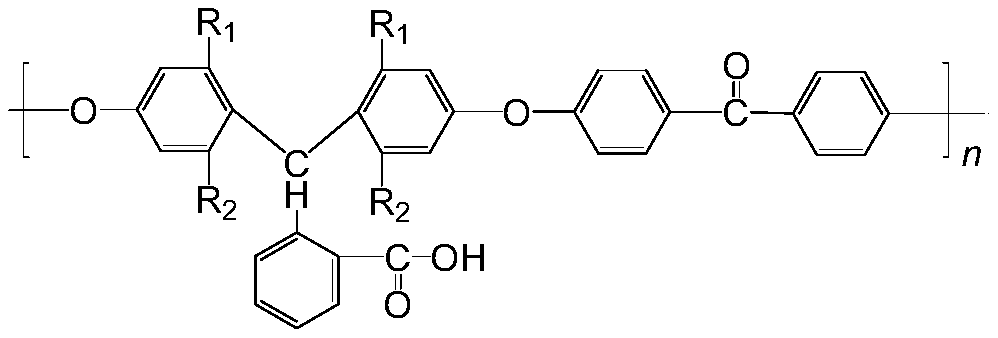

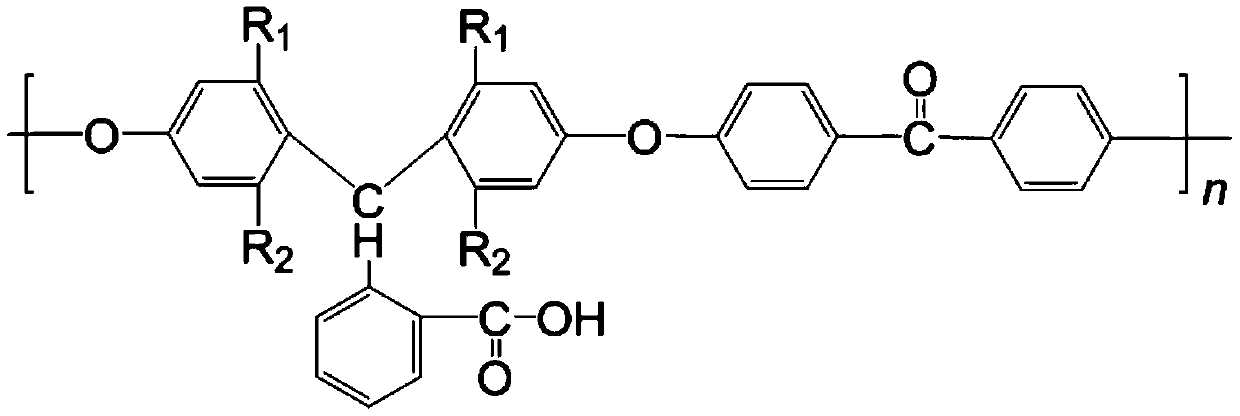

[0030] Example 1: Weigh 0.5g of graphene oxide (GO), ultrasonically disperse it in 500mL of N,N-dimethylformamide DMF solvent, and add 10.0g of toluene diisocyanate under stirring condition for reaction, the reaction temperature is 30°C , The reaction time is 24h. After the reaction was completed, it was filtered and washed three times with DMF to obtain toluene diisocyanate-modified graphene oxide. Dissolve 5.0g PEK-1 ultrasonically in 500mL DMF, then immediately add the toluene diisocyanate-modified graphene oxide prepared above, ultrasonically disperse and mix, add a catalytic amount of dibutyltin dilaurate under stirring conditions, and then react at 120°C 8h. Cool, filter, and dry in vacuum to obtain PEK-1 covalently grafted graphene oxide (GTPEK1). 1 part of GTPEK1, 0.05 part of butyl stearate, and 98.95 parts of polyether ether ketone resin were mechanically stirred and thoroughly mixed, and the composite material was prepared by a melt blending process, and the melti...

Embodiment 2

[0031] Example 2: Weigh 0.1g of GO, ultrasonically disperse it in 200mL of DMF solvent, and add 6.2g of diphenylmethane diisocyanate under stirring condition for reaction. The reaction temperature is 20°C and the reaction time is 48h. After the reaction was completed, it was filtered and washed three times with dimethyl sulfoxide DMSO to obtain diphenylmethane diisocyanate-modified graphene oxide. Dissolve 3.0g PEK-2 ultrasonically in 200mL DMSO, then immediately add the toluene diisocyanate-modified graphene oxide prepared above, ultrasonically disperse and mix, add a catalytic amount of dibutyltin dilaurate under stirring conditions, and then react at 150°C 4h. Cool, filter, and dry in vacuum to obtain PEK-1 covalently grafted graphene oxide (GMPEK2). 0.05 parts of GMPEK2, 0.01 parts of oxidized polyethylene wax, and 99.94 parts of polyether ketone ketone resin were mechanically stirred and thoroughly mixed, and the composite material masterbatch was prepared by melt blendi...

Embodiment 3

[0032] Example 3: Weigh 1.0 g of GO, ultrasonically disperse it in 200 mL of DMF solvent, and add 15.0 g of hexamethylene diisocyanate under stirring condition for reaction. The reaction temperature is 50° C. and the reaction time is 36 h. After the reaction was completed, it was filtered and washed three times with DMSO to obtain hexamethylene diisocyanate-modified graphene oxide. Dissolve 12.0g PEK-1 ultrasonically in 500mL DMSO, then immediately add the hexamethylene diisocyanate-modified graphene oxide prepared above, ultrasonically disperse and mix, add a catalytic amount of octyl stannous under stirring conditions, and then Under reaction 10h. Cool, filter, and dry in vacuum to obtain PEK-1 covalently grafted graphene oxide (GHPEK1). 5 parts of GHPEK1, 1 part of ethylene bisstearamide, and 94 parts of polyether ketone resin were mechanically stirred and mixed thoroughly, and the composite material masterbatch was prepared by melt blending, and the melt processing temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com