Preparation method of phenylboronic acid modified magnetic beta-cyclodextrin polymer and application of phenylboronic acid modified magnetic beta-cyclodextrin polymer in selective separation of shikimic acid

A technology of cyclodextrin polymer and phenylboronic acid, which is applied in the fields of alkali metal compounds, chemical instruments and methods, and other chemical processes, can solve the problems of strong non-specific adsorption of materials, low product purity, and poor method selectivity, and achieve High surface reactivity, high adsorption capacity, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of phenylboronic acid modified magnetic β-cyclodextrin polymer, comprises the steps:

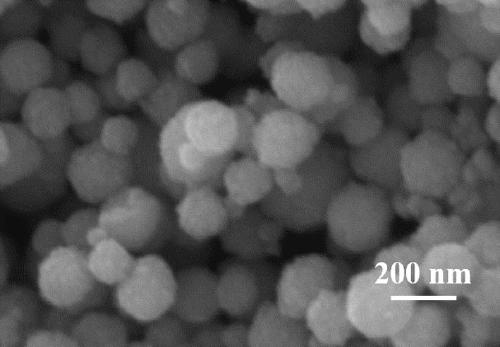

[0033] a) According to the solid-to-liquid ratio of 1.5mmol:3.5mmol:0.5mmol:100mL, FeCl 3 ·6H 2 O, NaAc 3H 2 O and Na 3 C 6 h 5 o 7 2H 2 O was dissolved in ethylene glycol, fully stirred and dissolved, transferred to a hydrothermal reaction kettle, placed in a blast drying oven at 120°C, reacted for 12 hours, centrifuged, washed with distilled water and absolute ethanol three times, and dried at 75°C Nano Fe3 o 4 solid;

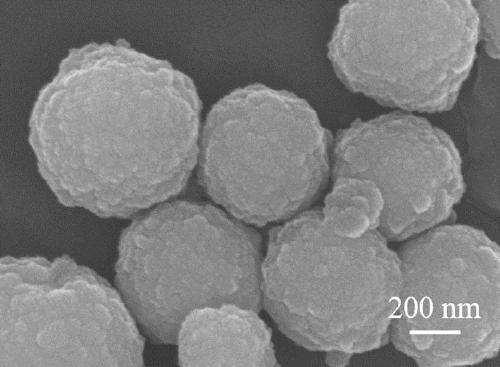

[0034] b) Weigh 0.1g dopamine hydrochloride and 0.2g Fe 3 o 4 Dissolve in 100mL aqueous solution containing 0.1211g Tris, stir well, adjust pH to 8.5 with hydrochloric acid, stir for 4h, centrifuge, wash with distilled water five times, dry at 75°C to get Fe 3 o 4 @PDA Solid;

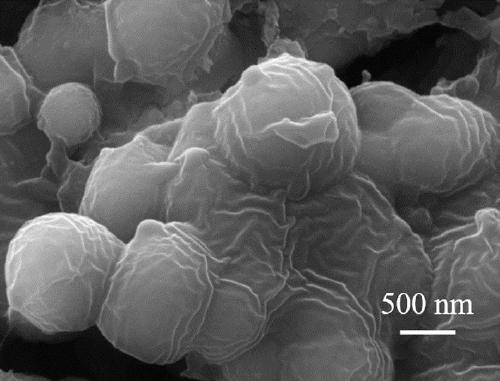

[0035] c) Prepare 40 mL of 7% sodium hydroxide aqueous solution, add 6 g of β-cyclodextrin and 1.92 g of epichlorohydrin into the prepared sodium hydr...

Embodiment 2

[0043] A kind of preparation method of phenylboronic acid modified magnetic β-cyclodextrin polymer, comprises the steps:

[0044] a) According to the solid-to-liquid ratio of 0.5mmol:2.5mmol:0.25mmol:60mL, the FeCl 3 ·6H 2 O, NaAc 3H 2 O and Na 3 C 6 h 5 o 7 2H 2 O was dissolved in ethylene glycol, fully stirred and dissolved, transferred to a hydrothermal reaction kettle, placed in a blast drying oven at 180°C, reacted for 10 hours, centrifuged, washed three times with distilled water and absolute ethanol, and dried at 75°C Nano Fe 3 o 4 solid;

[0045] b) Weigh 0.1g dopamine hydrochloride and 0.12g Fe 3 o 4 Dissolve in 100mL aqueous solution containing 0.1211g Tris, stir well, adjust pH to 8.5 with hydrochloric acid, stir for 4h, centrifuge, wash with distilled water five times, dry at 75°C to get Fe 3 o 4 @PDA Solid;

[0046] c) Prepare 40 mL of 7% sodium hydroxide aqueous solution, add 0.4 g of β-cyclodextrin and 0.96 g of epichlorohydrin into the prepared so...

Embodiment 3

[0054] A kind of preparation method of phenylboronic acid modified magnetic β-cyclodextrin polymer, comprises the steps:

[0055] a) According to the solid-to-liquid ratio of 2mmol:5mmol:0.5mmol:120mL, FeCl 3 ·6H 2 O, NaAc 3H 2 O and Na 3 C 6 h 5 o 7 2H 2 O was dissolved in ethylene glycol, fully stirred and dissolved, transferred to a hydrothermal reaction kettle, placed in a blast drying oven at 200°C, reacted for 14 hours, centrifuged, washed with distilled water and absolute ethanol three times, and dried at 75°C Nano Fe 3 o 4 solid;

[0056] b) Weigh 0.5g dopamine hydrochloride and 0.2g Fe 3 o 4 Dissolve in 100mL aqueous solution containing 0.1211g Tris, stir well, adjust pH to 8.5 with hydrochloric acid, stir for 6h, centrifuge, wash with distilled water five times, dry at 75°C to get Fe 3 o 4 @PDA Solid;

[0057] c) Prepare 40 mL of 7% sodium hydroxide aqueous solution, add 8 g of β-cyclodextrin and 3.84 g of epichlorohydrin into the prepared sodium hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com