Solution spray type thermosetting electrospun composite membrane and preparation method and application thereof

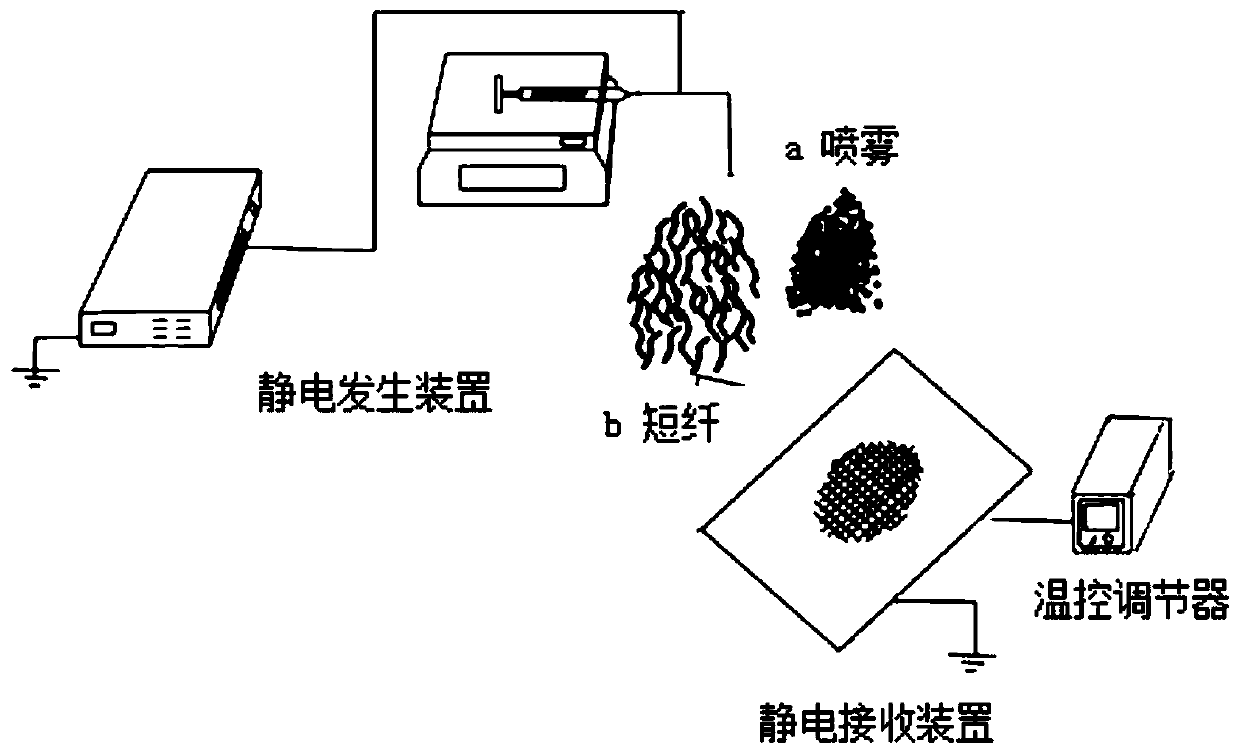

A technology of electrospinning and composite film, which is applied in the direction of electrospinning, filament forming treatment, filament/thread forming, etc. It can solve the problems affecting the stability of material film formation, fiber re-melting, fiber sticking, etc., to achieve The effect of controlling microscopic morphology, high water flux, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation of electrospun composite film of melt-spray type thermosetting forming, concrete steps are:

[0035] 1) Dissolve 1.8g of polyacrylonitrile in 15mL of acetone / N,N-dimethylacetamide (DMAc) mixture, wherein the volume ratio of acetone to DMAc is 2:3, and place the mixed solution in a 60°C water bath Constant temperature magnetic stirring was carried out for 2.5 h until a uniform transparent polymer solution was obtained.

[0036] 2) After obtaining a uniform transparent polymer solution, weigh 0.18 g of finely ground silicon dioxide powder and add it into the polymer solution, and continue ultrasonic stirring at 60° C. for 30 min.

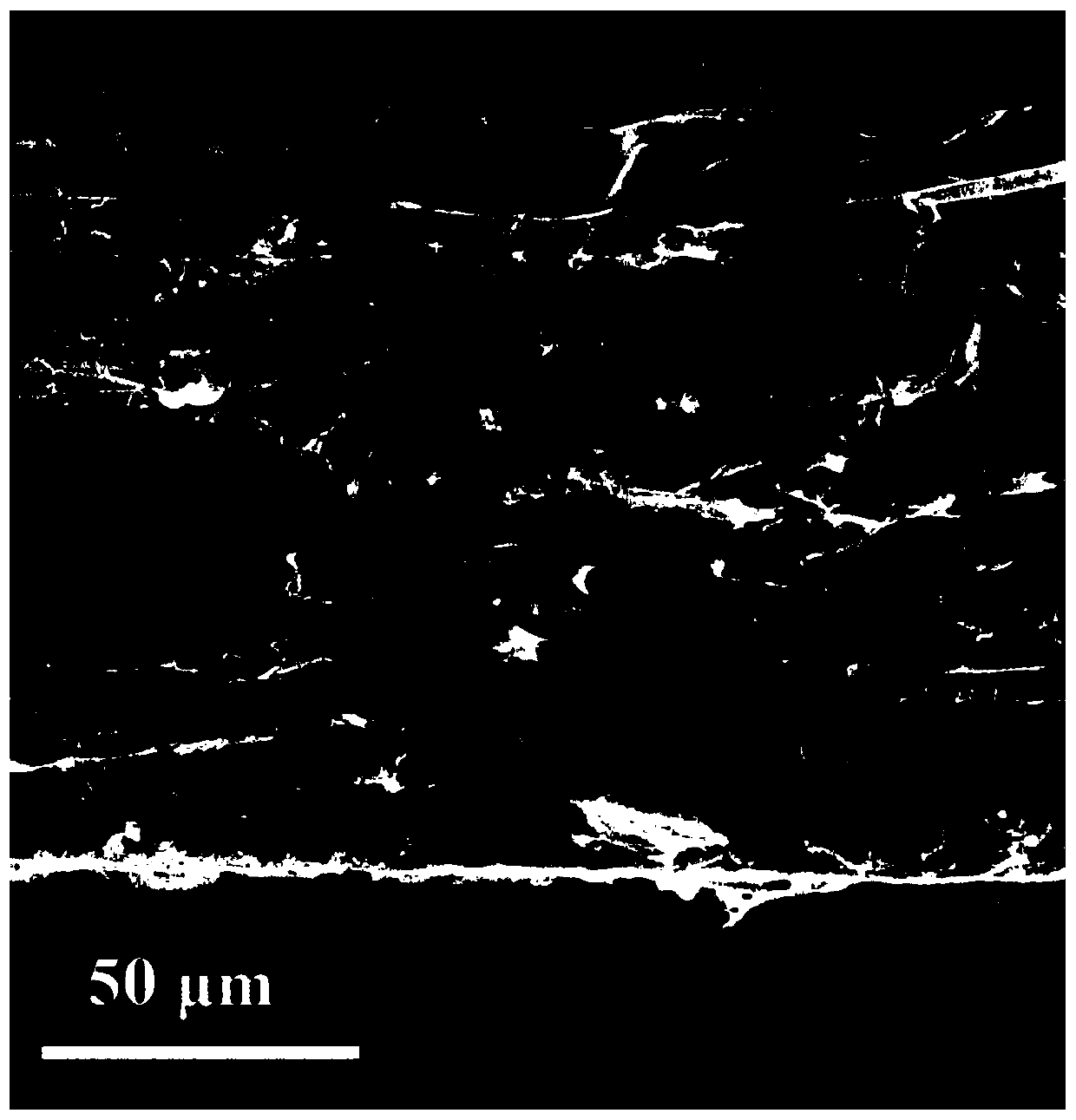

[0037] 3) After stirring, let stand for defoaming for 30 minutes and introduce it into the syringe to start electrospinning. The parameters of electrospinning are: receiving distance 15cm, voltage 14kV, relative humidity 45%, liquid feeding speed 2.5mL / h, receiving panel The temperature was controlled at 50°C, and the spi...

Embodiment 2

[0040] A kind of preparation of electrospun composite film of melt-spray type thermosetting forming, concrete steps are:

[0041] 1) Weigh 5.04g of polyethersulfone and dissolve it in 20mL of ethanol / chloroform mixture, wherein the volume ratio of ethanol to chloroform is 1:9, and stir the mixed solution in a water bath at 50°C for 2.0h until the obtained Homogeneous transparent polymer solution.

[0042] 2) After obtaining a uniform transparent polymer solution, weigh 0.52 g of finely ground titanium dioxide powder and add it into the polymer solution, and continue ultrasonic stirring at 50° C. for 30 min.

[0043] 3) After stirring, let stand for defoaming for 30 minutes, and then introduce it into the syringe to start electrospinning. The spinning parameters are set as: receiving distance 10cm, voltage 15kV, relative humidity 45%, liquid feeding speed 1mL / h, receiving panel temperature The temperature is controlled at 60°C, and after spinning, it is left at room temperatur...

Embodiment 3

[0045] A kind of preparation of electrospun composite film of melt-spray type thermosetting forming, concrete steps are:

[0046] 1) Dissolve 0.85g and 1.8g of cellulose acetate (CA) in 10mL of acetone / N,N-dimethylacetamide (DMAc) mixture, wherein the volume ratio of acetone to DMAc is 1:1, and The mixed solution was magnetically stirred in a water bath at 60° C. for 2.5 hours until a uniform transparent polymer solution was obtained.

[0047]2) After obtaining a uniform transparent polymer solution, weigh 0.0042 g and 0.023 g of finely ground activated carbon powder and add them to the polymer solution, respectively, and continue ultrasonic stirring at 60° C. for 30 min.

[0048] 3) After the stirring is completed, let stand for defoaming for 30 minutes, and then introduce them into the injection cylinder respectively to obtain electrospinning solution a and electrospinning solution b.

[0049] 4) Firstly, the electrospinning spinning liquid b was spun, and the spinning para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com