Preparation method of pH and temperature responsive double-shell hollow microspheres

A hollow microsphere and temperature-responsive technology, which is applied to the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems that the preparation technology needs to be improved, and achieve the advantages of simple and fast preparation method, low density and high luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Take 3.8mL of silane coupling agent vinyltriethoxysilane (KH-151) and 26.2mL of water, add it into a 100mL single-necked flask, and stir magnetically at room temperature until the mixture is uniform. Adjust the pH value of the solution system between 3 and 4 with dilute hydrochloric acid, and continue stirring for 1 hour to hydrolyze the solution under acidic conditions, and the solution turns from light white to transparent. Then use dilute ammonia solution to quickly adjust the pH value of the solution system to between 10 and 11, stop stirring, and let it stand for 15 hours. The product is separated, centrifuged with water and ethanol, washed ultrasonically for 3 to 5 times, and vacuum-dried at 50° C. to obtain polyvinylsiloxane (PVSI) microspheres.

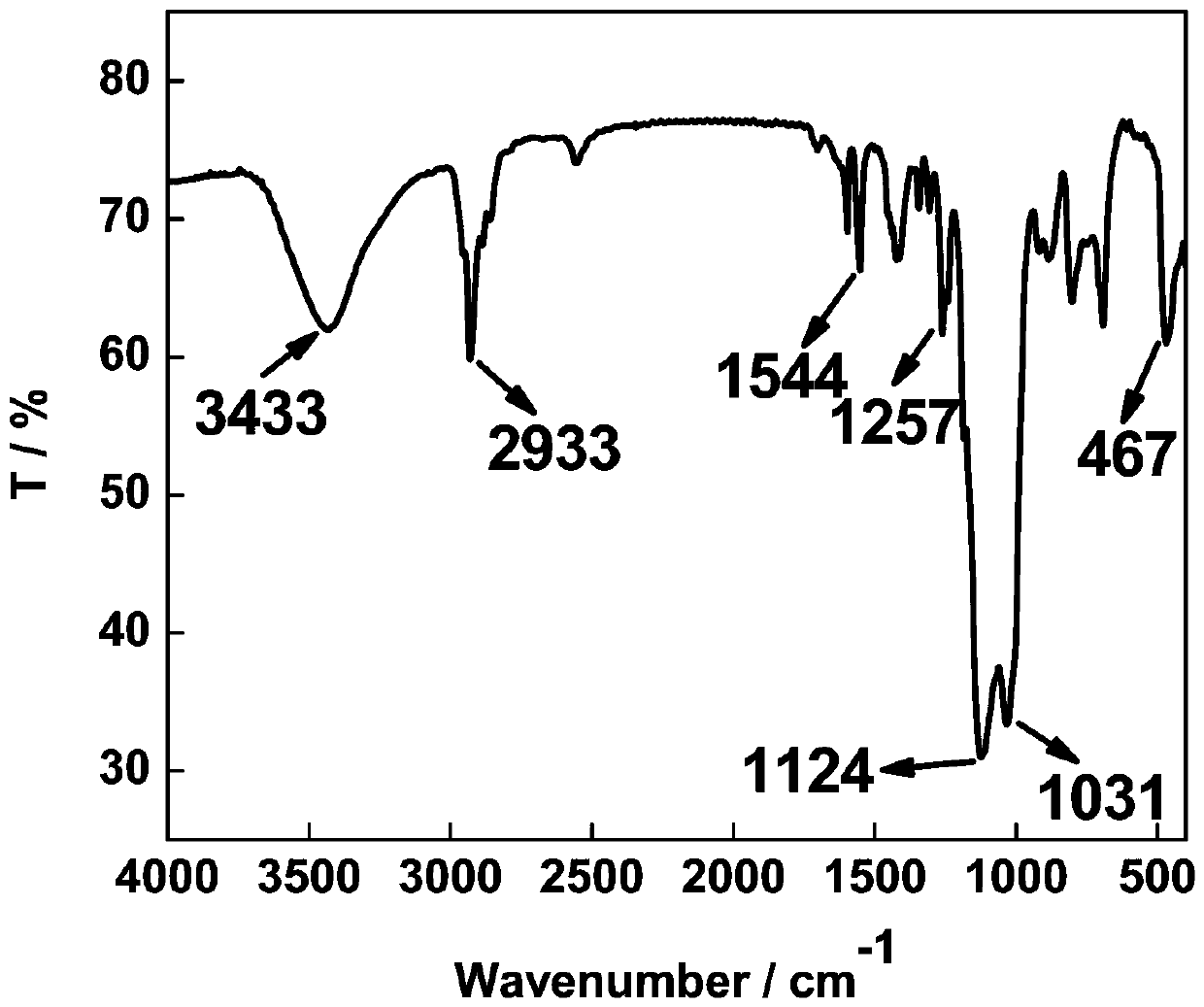

[0050] figure 1 In the infrared spectrum of PVSI microspheres, 3433cm -1 is the Si-OH stretching vibration peak at 2933cm -1 Where is silicon vinyl (Si-CH=CH 2 ) in the Si-C bond absorption peak, 1544cm -1 where Si...

Embodiment 2

[0053] Add 0.2g of PVSI microspheres prepared in Example 1 to 40mL of acetonitrile, ultrasonically disperse for 10min, transfer to a 100mL two-necked flask, add 0.3g of methacrylic acid (MAA), 0.2g of crosslinking agent N,N'-methylene Bisacrylamide (MBA), 0.1g initiator azobisisobutyronitrile (AIBN), heating to reflux for polymerization reaction, distilling 20mL of acetonitrile within 1.5 to 2h to end the reaction. After centrifugation with acetonitrile and ethanol, ultrasonic washing, and vacuum drying at 50°C, cross-linked polysiloxane@polymethacrylic acid (PVSI@PMAA) core-shell microspheres were obtained.

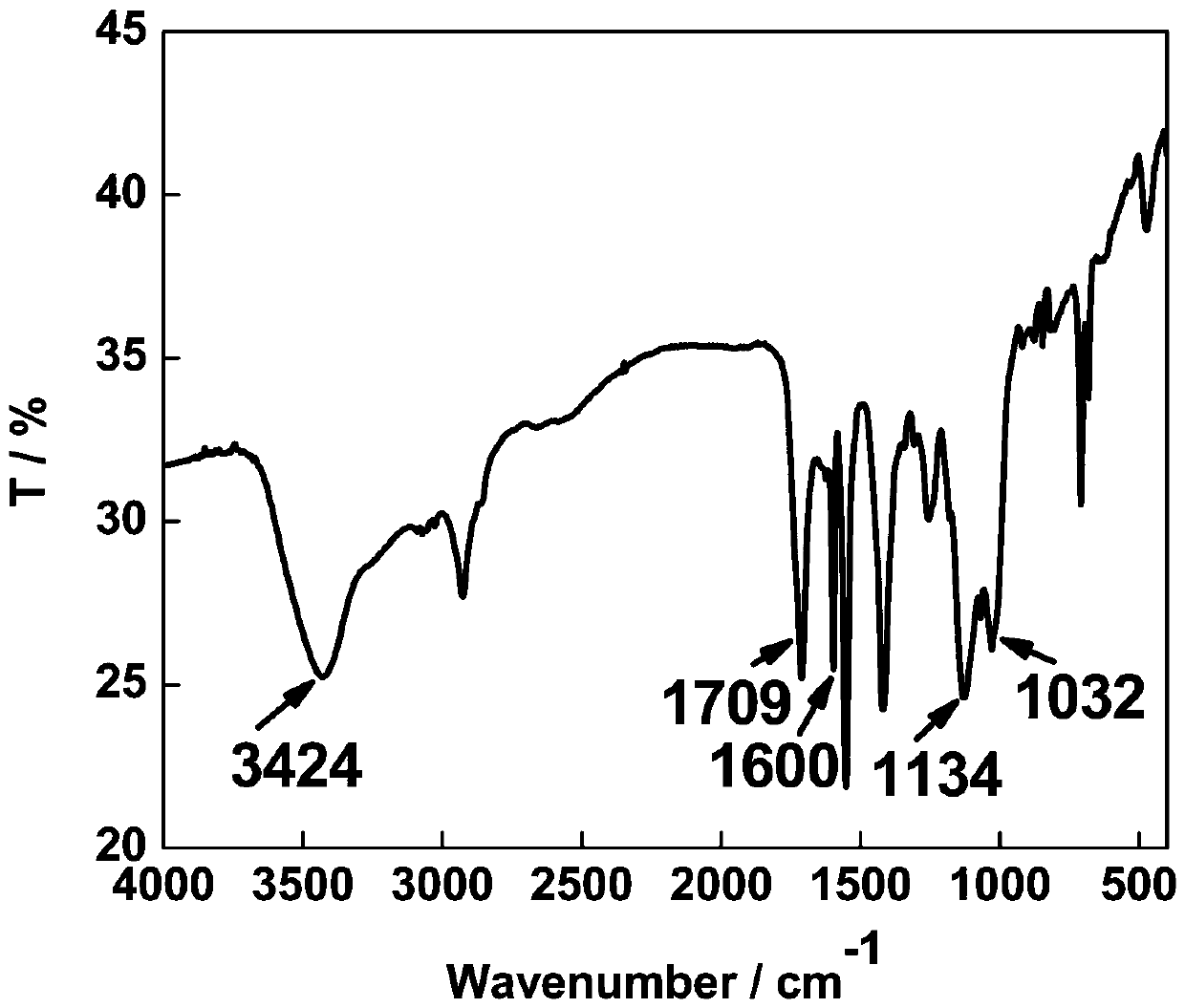

[0054] image 3 The infrared spectra of the prepared PVSI@PMAA core-shell microspheres are given. In the picture, 3424cm -1 is the Si-OH stretching vibration peak, 1600cm -1 where Si-CH=CH 2 Stretching vibration absorption peak, 1709cm -1 is the C=O stretching vibration peak of carboxylic acid, 1134, 1032cm -1 The broad peak is the characteristic absorption peak of...

Embodiment 3

[0057] Add 0.2 g of the PVSI@PMAA core-shell microspheres prepared in Example 2 above and 2.4 mL of ammonia water into a three-necked flask filled with 20 mL of water and 160 mL of absolute ethanol, and, under vigorous stirring at room temperature, dissolve 0.8 mL of ethyl orthosilicate within 1 h. The ester (TEOS) was slowly added dropwise into the flask, and the stirring reaction was continued for 6h. Then 0.2 mL of vinyltriethoxysilane (KH-151) was slowly added into the solution, and the reaction was terminated after 18 hours of reaction. The product was centrifuged and washed with ethanol and water in sequence to prepare a cross-linked polysiloxane@polymethacrylic acid@silicon dioxide (PVSI@PMAA@SiO2) with double bonds on the surface. 2 -CH=CH 2 ) three-layer composite microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com