Method for preparing lithium iron phosphate cathode material with high-compaction and high-rate performance

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of phosphate, phosphorus oxyacids, chemical instruments and methods, etc., can solve the problems of single high rate or high compaction performance, poor low temperature performance, poor processing performance, etc., to achieve Effect of improving compaction and charge-discharge rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

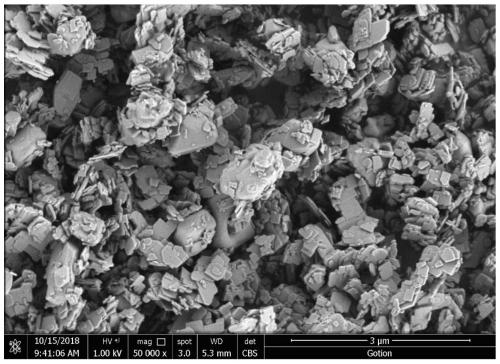

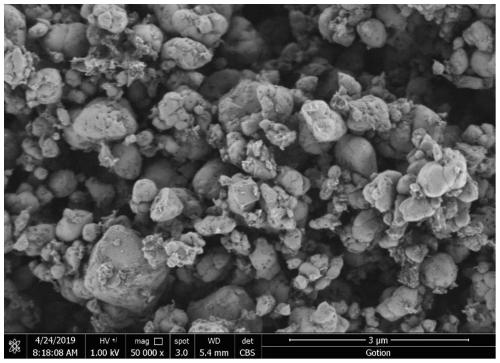

Image

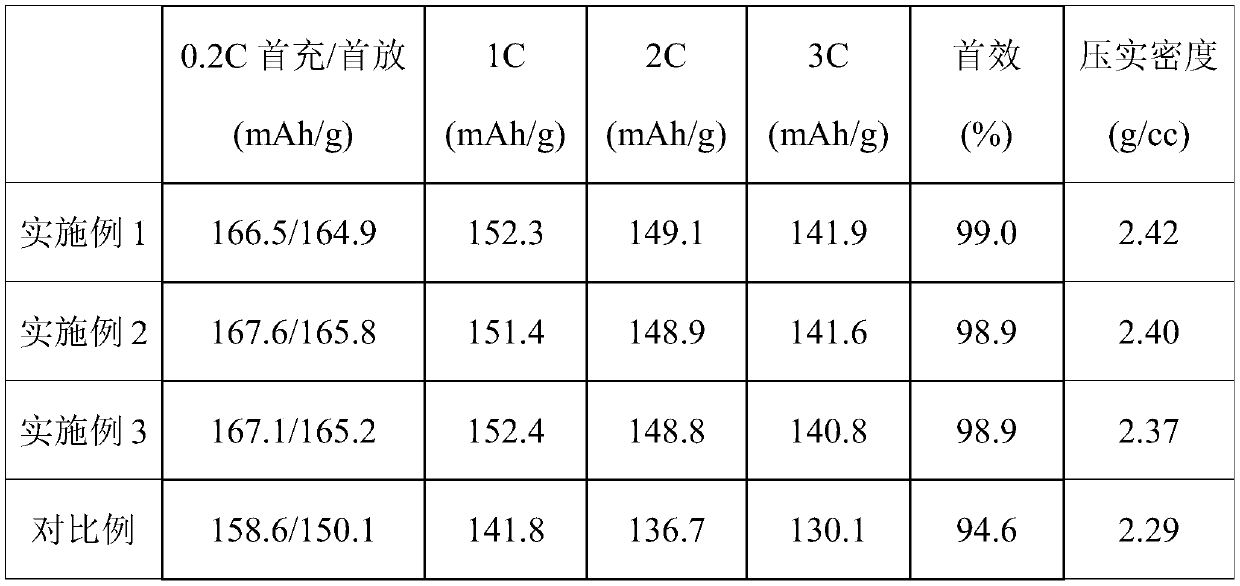

Examples

Embodiment 1

[0024] (1) Dissolve urea and ammonium sulfate in ultrapure water at a mass ratio of 11.5:1, prepare a solution with a solid content of 55%, dry at 70°C for 20 hours to obtain a dry material, and then sinter the dry material in a tube furnace at 570°C 7h obtains powder sample, powder sample is carried out ultrasonic exfoliation 12h in ultrapure water, obtains 100nm thickness layered mesoporous graphite phase carbon nitride powder (g-C 3 N 4 );

[0025] (2) Weigh g-C in step (1) according to the mass ratio of 100:4.5:1 3 N 4 1. PVP and glucose with a relative molecular weight of 10,000 were added to deionized water and dispersed for 40 minutes to obtain dispersion A;

[0026] (3) According to FePO 4 :g-C 3 N 4 =50:1 mass ratio, weigh FePO 4 , added to the dispersion A in step (2) and dispersed for 1h to obtain dispersion B, then according to the stoichiometric ratio Fe:Li=1:1, weigh the lithium source, add it to dispersion B and disperse for 2.5h to obtain dispersion Liq...

Embodiment 2

[0030] (1) Dissolve urea and ammonium sulfate in ultrapure water at a mass ratio of 11.5:1, prepare a solution with a solid content of 55%, dry at 70°C for 20 hours to obtain a dry material, and then sinter the dry material in a tube furnace at 570°C 7h obtains powder sample, powder sample is carried out ultrasonic exfoliation 12h in ultrapure water, obtains 100nm thickness layered mesoporous graphite phase carbon nitride powder (g-C 3 N 4 );

[0031] (2) Weigh g-C in step (1) according to the mass ratio of 100:4.5:0.5 3 N 4 1. PVP and glucose with a relative molecular weight of 10,000 were added to deionized water and dispersed for 40 minutes to obtain dispersion A;

[0032] (3) According to FePO 4 :g-C 3 N 4 =50:1 mass ratio, weigh FePO 4 , added to the dispersion A in step (2) and dispersed for 1h to obtain dispersion B, then according to the stoichiometric ratio Fe:Li=1:1, weigh the lithium source, add it to dispersion B and disperse for 2.5h to obtain dispersion L...

Embodiment 3

[0035] (1) Dissolve urea and ammonium sulfate in ultrapure water at a mass ratio of 11.5:1, prepare a solution with a solid content of 55%, dry at 70°C for 20 hours to obtain a dry material, and then sinter the dry material in a tube furnace at 570°C 7h obtains powder sample, powder sample is carried out ultrasonic exfoliation 12h in ultrapure water, obtains 100nm thickness layered mesoporous graphite phase carbon nitride powder (g-C 3 N 4 );

[0036] (2) Weigh g-C in step (1) according to the mass ratio of 100:4.5:4 3 N 4 1. PVP and glucose with a relative molecular weight of 10,000 were added to deionized water and dispersed for 40 minutes to obtain dispersion A;

[0037] (3) According to FePO 4 :g-C 3 N 4 =50:1 mass ratio, weigh FePO 4 , added to the dispersion A in step (2) and dispersed for 1h to obtain dispersion B, then according to the stoichiometric ratio Fe:Li=1:1, weigh the lithium source, add it to dispersion B and disperse for 2.5h to obtain dispersion Liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com