Environment-friendly fluorine-free foaming agent and preparation method thereof

A foaming agent and an environmentally friendly technology, which is applied in the field of environmentally friendly fluorine-free foaming agent and its preparation, can solve the problems of being unable to meet the temperature requirements of the artificial leather coating method and calendering method, limiting the scope of use, and not being suitable for the artificial leather production process. High market promotion and application value, good foam stability, green effect in use and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

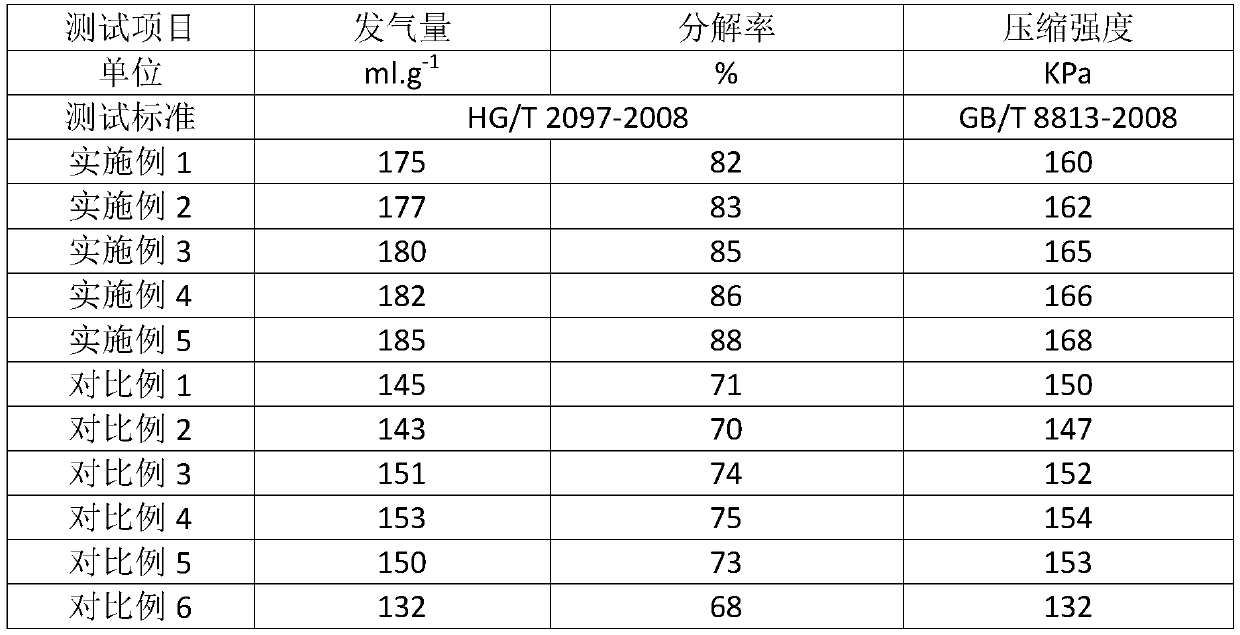

Examples

Embodiment 1

[0024] An environmentally friendly fluorine-free foaming agent, made of the following raw materials in parts by weight: 4 parts of sulfonylhydrazide bis(2-hydroxyethyl)-2-aminoethanesulfonic acid carbonate, poly-1,4- 3 parts of N-nitrosodiisopropanolamine cyclohexanedicarboxylate, 0.3 part of sodium glycinate carbonate, 0.5 part of triethanolamine oleic acid soap, 0.1 part of cyclopentyl-N-succinimidyl carbonate .

[0025] The preparation method of the sulfonylhydrazide bis(2-hydroxyethyl)-2-aminoethanesulfonic acid carbonate comprises the steps of: 1,2-bis(methylsulfonyl)-1-(2-chloro Add 14.4g of ethyl)-2-(methylaminocarbonyl)hydrazine and 10g of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid into 80g of ether, and stir the reaction at 40°C for 6 hours. Afterwards, the solvent was removed by rotary evaporation, washed 3 times with ether, and then the ether was removed by rotary evaporation, and then added to 100 g of an aqueous solution of sodium carbonate with a mass fr...

Embodiment 2

[0029] An environmentally friendly fluorine-free blowing agent, made of the following raw materials in parts by weight: 5 parts of sulfonylhydrazide bis(2-hydroxyethyl)-2-aminoethanesulfonic acid carbonate, poly-1,4- 4 parts of N-nitrosodiisopropanolamine cyclohexanedicarboxylate, 0.4 part of sodium glycinate carbonate, 0.6 part of triethanolamine oleic acid soap, 0.2 part of cyclopentyl-N-succinimidyl carbonate .

[0030]The preparation method of the sulfonylhydrazide bis(2-hydroxyethyl)-2-aminoethanesulfonic acid carbonate comprises the steps of: 1,2-bis(methylsulfonyl)-1-(2-chloro Add 14.4g of ethyl)-2-(methylaminocarbonyl)hydrazine and 10g of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid into 95g of ethyl acetate, and stir the reaction at 45°C for 6.5 hour, and then the solvent was removed by rotary evaporation, washed 4 times with diethyl ether, and then the ether was removed by rotary evaporation, and then added in 130 g of an aqueous solution of sodium carbonate w...

Embodiment 3

[0034] An environmentally friendly fluorine-free foaming agent, made of the following raw materials in parts by weight: 7 parts of sulfonylhydrazide bis(2-hydroxyethyl)-2-aminoethanesulfonic acid carbonate, poly-1,4- 4.5 parts of N-nitrosodiisopropanolamine cyclohexanedicarboxylate, 0.45 parts of sodium glycinate carbonate, 0.8 parts of triethanolamine oleic acid soap, 0.25 parts of cyclopentyl-N-succinimidyl carbonate .

[0035] The preparation method of the sulfonylhydrazide bis(2-hydroxyethyl)-2-aminoethanesulfonic acid carbonate comprises the steps of: 1,2-bis(methylsulfonyl)-1-(2-chloro Add 14.4g of ethyl)-2-(methylaminocarbonyl)hydrazine and 10g of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid into 100g of acetone, and stir the reaction at 50°C for 7 hours. Afterwards, the solvent was removed by rotary evaporation, washed 4 times with ether, and after the ether was removed by rotary evaporation, the mass fraction was added in 150 g of an aqueous solution of sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com