Moving bed C3/C4 alkane dehydrogenation process

A technology of alkane dehydrogenation and moving bed, which is applied in the field of C3/C4 alkane dehydrogenation to olefins in the petrochemical industry. It can solve the problems of shortening catalyst life, aggravating catalyst carbon deposition, improving the third-stage reactor, etc., and reducing energy consumption. , high conversion rate and selectivity, and the effect of lowering the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

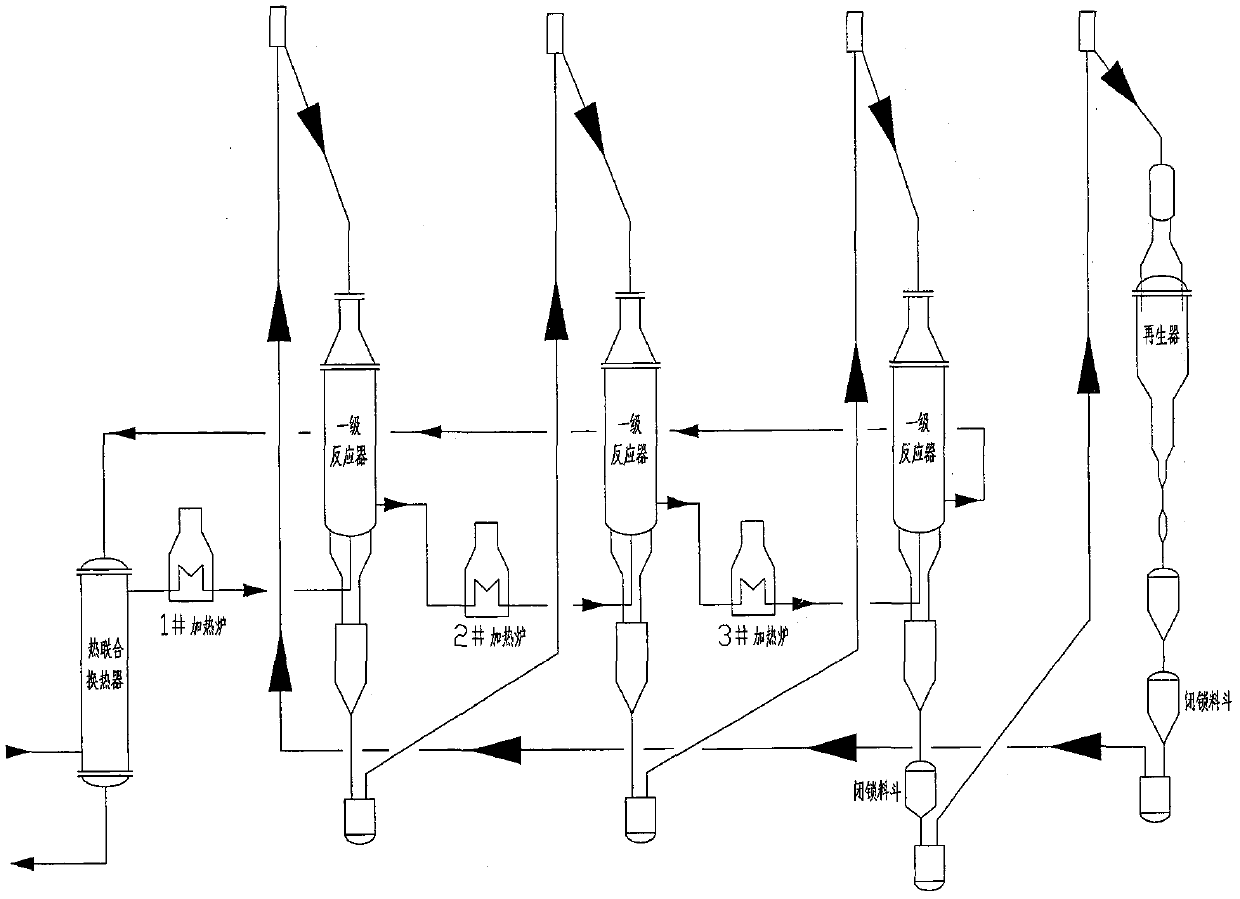

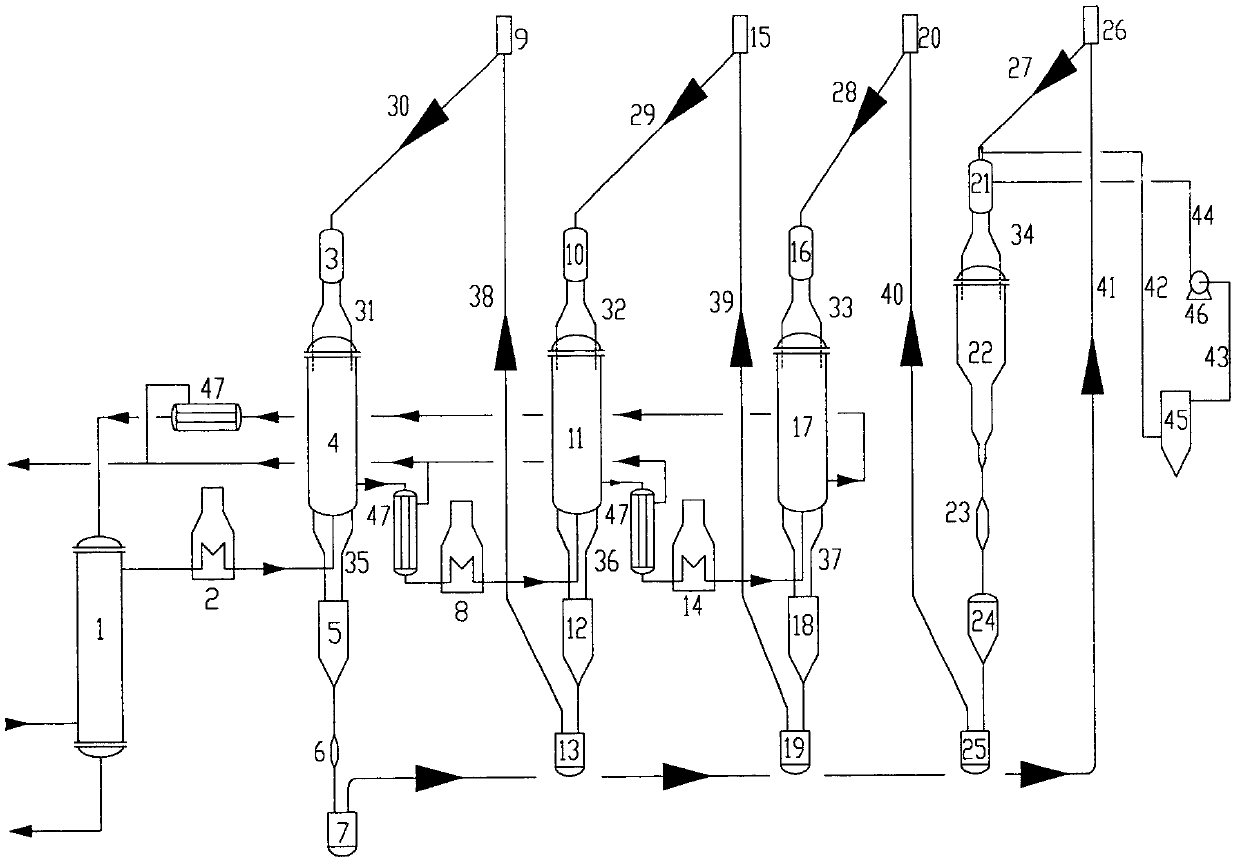

[0073] This example uses the raw materials in Table 1 and the catalysts in Table 2, taking 300,000 tons / year of propane dehydrogenation as an example, using a countercurrent moving bed C3 / C4 alkane dehydrogenation process, including a 3-stage reaction system, and catalyst regeneration system, catalyst circulation system, dust separation system, hydrogen permeable membrane separator. The fresh reactant stream flows from the first-stage reactor to the third-stage reactor in sequence, and the catalyst stream flows from the third-stage reactor to the first-stage reactor in sequence, and the moving direction of the catalyst stream in each reactor is related to the reaction The material flow is opposite and countercurrent, that is, the regenerated catalyst enters from the third-stage reactor and flows out from the first-stage reactor into the regenerator. The fresh reactant stream enters the first-stage reactor, and the partial pressure of the product gas is zero, and the reaction i...

Embodiment 2

[0075] This example uses the raw materials in Table 1 and the catalysts in Table 2, taking 300,000 tons / year of propane dehydrogenation as an example, using a countercurrent moving bed C3 / C4 alkane dehydrogenation process, including a 3-stage reaction system, and catalyst regeneration system, catalyst circulation system, dust separation system, hydrogen permeable membrane separator. The fresh reactant stream flows from the first-stage reactor to the third-stage reactor in sequence, and the catalyst stream flows from the third-stage reactor to the first-stage reactor in sequence, and the moving direction of the catalyst stream in each reactor is related to the reaction The material flow is opposite and countercurrent, that is, the regenerated catalyst enters from the third-stage reactor and flows out from the first-stage reactor into the regenerator. The fresh reactant stream enters the first-stage reactor, and the partial pressure of the product gas is zero, and the reaction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com