Composite electrolyte membrane and preparation method and application thereof

A composite electrolyte membrane and electrolyte technology, which is applied in the field of solid electrolytes, can solve the problems of reducing the mechanical strength and energy density of electrolytes, the inability to ensure complete filling of electrolyte materials, and reducing the movement capacity of molecular chains, so as to reduce the risk of thermal runaway and ensure mechanical strength. and ionic conductivity, and the effect of improving the safety performance of thermal abuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

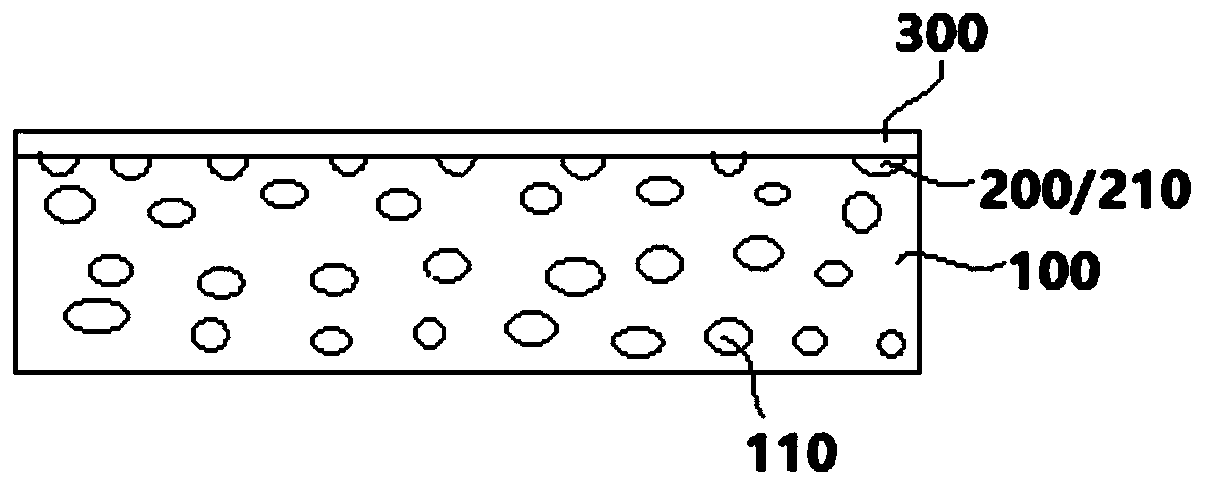

[0058] According to the method for preparing a composite electrolyte membrane according to an embodiment of the present invention, the porous membrane substrate is filled with hot-melt polymer filler particles, which is conducive to reducing the pore size and porosity of the porous membrane substrate, and at the same time, when the heating temperature of the composite electrolyte membrane reaches the thermal melting point At the melting point of the polymer filler particles, the hot-melt polymer filler particles melt and penetrate into the surface of the adjacent organic-inorganic electrolyte particles. Because the hot-melt polymer filler particles have insulating properties, the effect of cutting off the conductive path is achieved. Reduce the risk of thermal runaway and improve the safety performance of battery thermal abuse; further, the organic-inorganic electrolyte filling layer can make the composite electrolyte membrane have high density, which can effectively ensure the ...

Embodiment 1

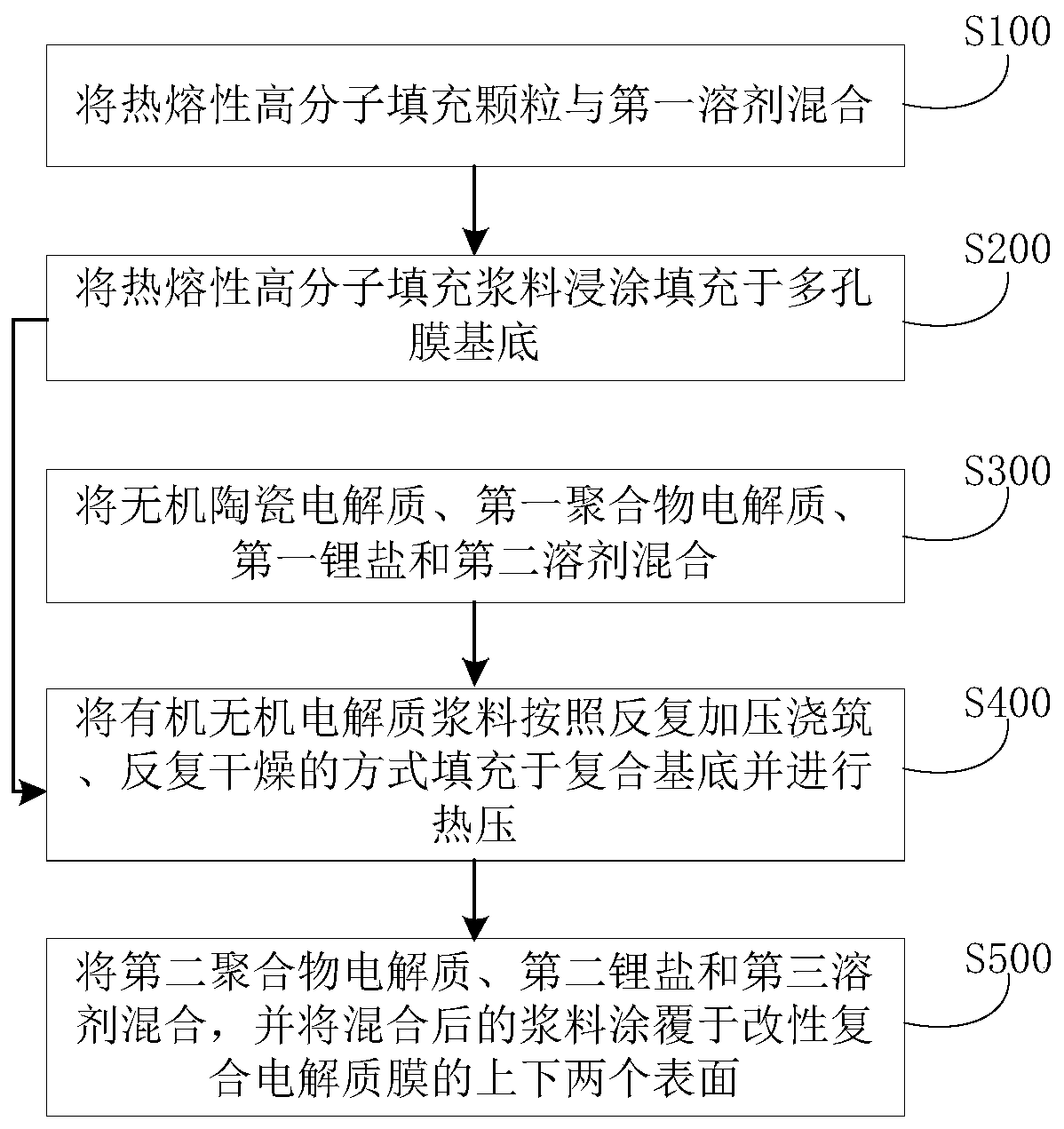

[0063] Mix hot-melt polymer filled particles modified ethylene-vinyl acetate copolymer with a melting point of 125°C and an average particle size of 0.5 μm, binder SBR and deionized water as the first solvent to obtain a solid content of 20 wt%. Hot-melt polymer filling slurry with a viscosity of 400mPa.s;

[0064] The hot-melt polymer filling slurry is dip-coated and filled in the electrospinning polyimide porous membrane substrate with a thickness of 15 μm, a porosity of 90%, and an average pore diameter of 10 μm, and then dried to obtain a composite substrate. The coating time is 2 minutes, and the drying temperature is 80°C;

[0065] The inorganic ceramic electrolyte LAGP ceramic oxide and the first polymer electrolyte modified PEO-based organic polymer, the first lithium salt LiCLO 4 mixed with a second solvent, acetonitrile, so as to obtain an organic-inorganic electrolyte slurry. Wherein, the mass ratio of the inorganic ceramic electrolyte to the first polymer electro...

Embodiment 2

[0069] Mix hot-melt polymer filled particle-modified polyethylene with a melting point of 130°C and an average particle size of 0.8 μm, binder LA133, and the first solvent deionized water to obtain a solid content of 15 wt % and a viscosity of 800 mPa. s hot-melt polymer filling paste;

[0070] Dip-coat the hot-melt polymer filling slurry into the porous film substrate PET non-woven fabric with a thickness of 20 μm, a porosity of 80%, and an average pore diameter of 6 μm, and obtain a composite substrate after drying. Among them, the dip-coating time 1min, drying temperature is 70°C;

[0071]The inorganic ceramic electrolyte LATP ceramic oxide, the first polymer electrolyte modified PPC-based organic polymer electrolyte, the first lithium salt LiTFSI, and the second solvent acetonitrile were mixed so as to obtain an organic-inorganic electrolyte slurry. Wherein, the mass ratio of the inorganic ceramic electrolyte to the first polymer electrolyte and the first lithium salt is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com