Baking-free brick made of industrial caustic sludge and making method of baking-free brick

An industrial alkali and non-burning brick technology, applied in the fields of municipal engineering and construction engineering, can solve the problems of weathering resistance, reduced wear resistance, large amount of raw materials, incomplete and insufficient, etc., so as to reduce CO2 emissions, reduce environmental pollution, reduce The effect of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 A kind of non-fired brick produced by utilizing industrial alkali slag

[0051] The non-burning brick produced by using industrial alkali slag of the present invention uses the alkaline waste slag of a local soda ash production enterprise to be pressed into a non-burning brick without sintering through appropriate proportion matching.

[0052] A non-burning brick produced by utilizing industrial alkali slag of the present invention, the required materials, by weight, include: 60 parts of alkali slag, 15 parts of cement, 15 parts of yellow sand, 0.5 part of water reducing agent, 2.5 parts of Parts of sludge, 2.5 parts of construction waste, 2 parts of fly ash, 3 parts of slag, 0.3 parts of colorant and 10-12 parts of water;

[0053] The alkali slag is the waste alkali slag produced in the production process of a soda ash production enterprise;

[0054] The composition and proportion of the spent alkali residue are: CaCO3: 50-70%, Ca(OH)2: 3-5%, CaO: 6.3-10%...

Embodiment 2

[0061] Embodiment 2 A kind of preparation method of the unfired brick that utilizes industrial alkali slag to produce comprises the following steps:

[0062] (1) Pretreatment: Weigh industrial waste alkali slag according to parts by weight, and carry out pretreatment;

[0063] The alkali slag is the waste alkali slag produced in the production process of a soda ash production enterprise;

[0064] The composition and proportion of the spent alkali residue are: CaCO3: 50-70%, Ca(OH)2: 3-5%, CaO: 6.3-10%, CaSO4: 2.5-5%, CaCL2: 8.5-10% , SiO2: 5-7%, the balance is trace metal compounds;

[0065] The trace metal compounds include, for example, aluminum oxide and iron oxide.

[0066] (2) Mixing: add cement, yellow sand, sludge, construction waste, and mix;

[0067] (3) Add water and stir: fully stir evenly to obtain a mixture;

[0068] (4) Compression molding: stack the above mixture at room temperature for 15 minutes, and then press molding;

[0069] (5) Curing: natural curing...

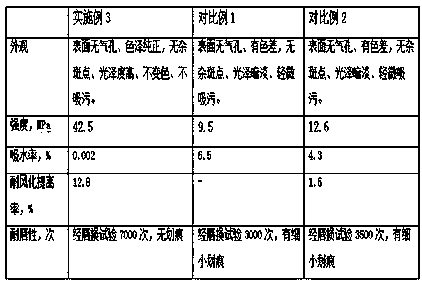

Embodiment 3

[0070] Embodiment 3 A kind of preparation method of the unfired brick that utilizes industrial alkali slag to produce, comprises the following steps:

[0071] (1) Pretreatment

[0072] Take raw materials by weight as follows:

[0073] 60 parts of alkali slag, 6 parts of desalted coal tar, 15 parts of cement, 15 parts of yellow sand, 0.5 parts of water reducing agent, 2.5 parts of sludge, 2.5 parts of construction waste, 2 parts of fly ash, 3 parts slag, 0.6 parts of sodium acetate, 0.3 parts of colorant and 10-12 parts of water.

[0074] The construction waste contains 20% slag, 10-15% waste concrete, 55.6-60.5% waste masonry, 5.5-8.0% construction glue, construction paint, and construction paint. The amount is other waste;

[0075] The fly ash has a density of 2.3kg / m 3 , the thermal conductivity is 9, the compressive strength is 39MPa, and the sound absorption coefficient is 8; the content of Al2O3 is ≥11.2%, the content of FeO is 5.2-10%, the content of Fe2O3 is 3.5-5.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com