Method for detecting residual solvent, monomer and initiator decomposition product of tertiary amine containing methacrylate copolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment is a method for detecting residual solvents, monomers and initiator decomposition products of tertiary amino methacrylate copolymers of the present invention

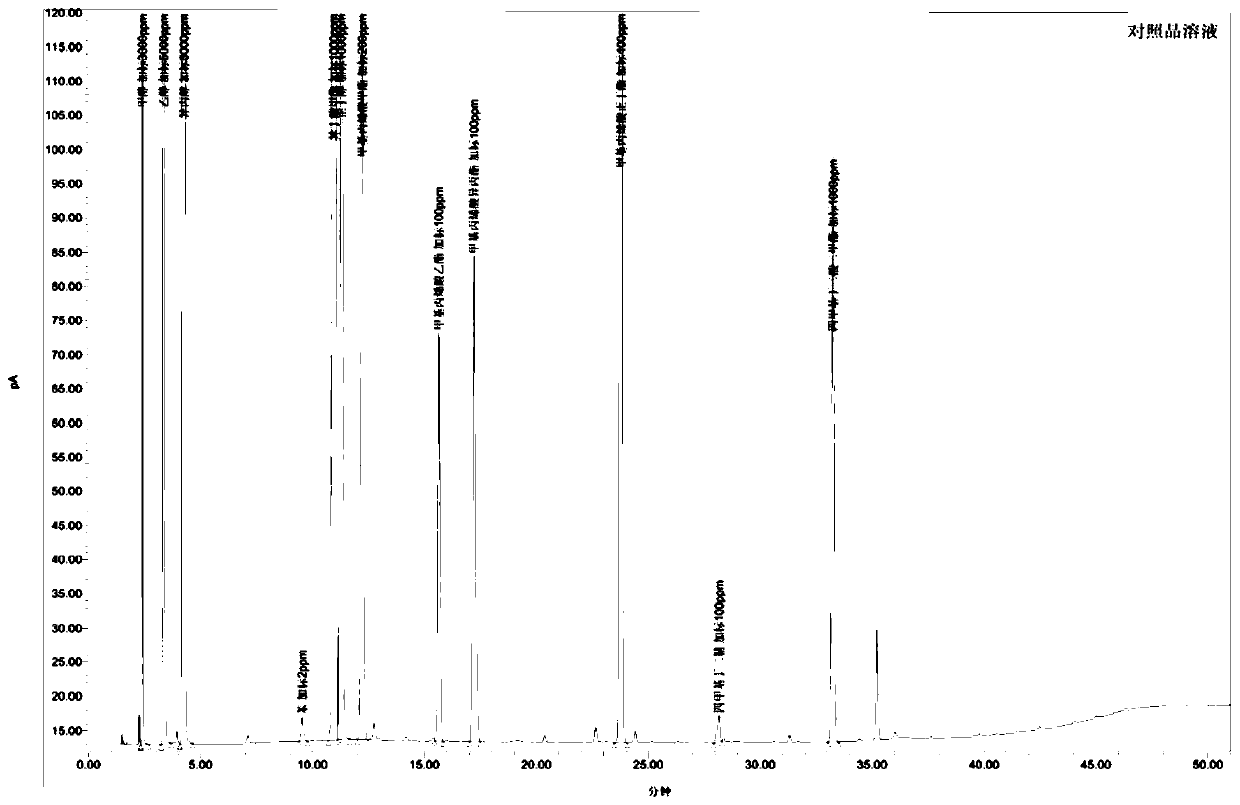

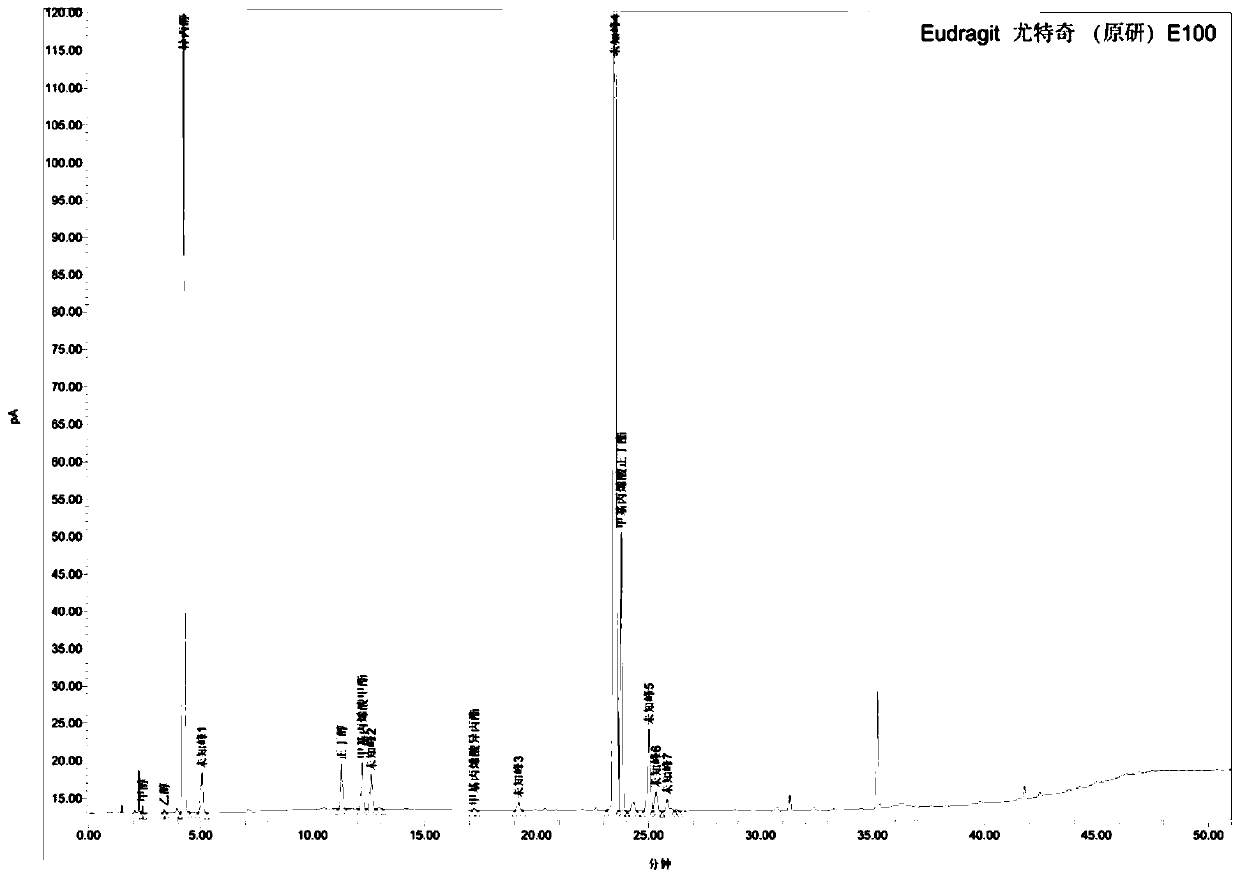

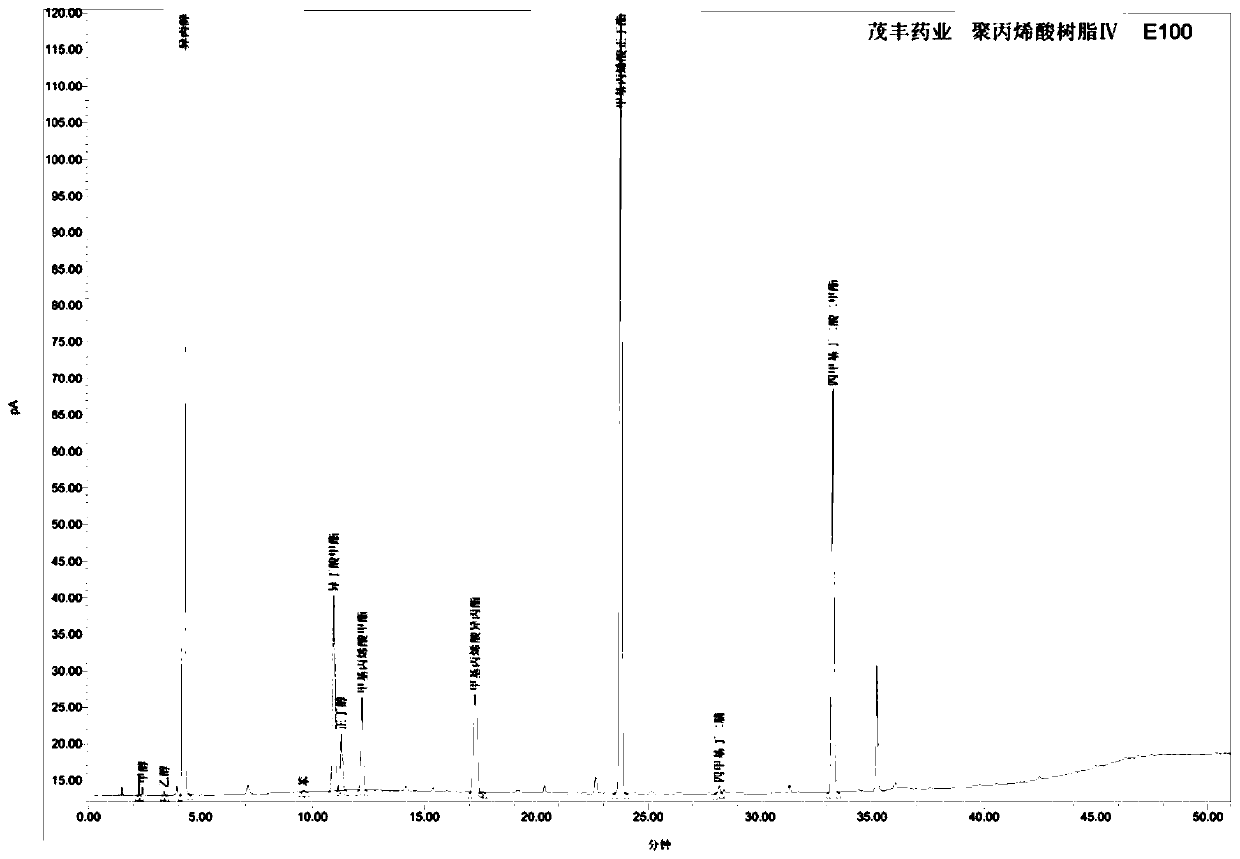

[0061] Test products: E100, a product from Evonik Rohm, Germany, E100, a product from Guangzhou Maofeng Pharmaceutical Co., Ltd., and polyacrylic resin IV from a domestic W / Z / S / A manufacturer. Test results such as Figure 1-Figure 7 Shown.

[0062] The method for detecting residual solvents, monomers and initiator decomposition products in the tertiary amino group-containing methacrylate copolymer includes the following steps:

[0063] (1) Preparation of test solution: Take about 70ml of phosphoric acid mixed solution (weigh 93.0g of phosphoric acid, 80.0g of anhydrous sodium sulfate and 5.0g of p-hydroxyanisole, add water to dissolve and dilute to 1000ml, shake well), set In a 150ml conical flask with stopper, electromagnetic stirring. Take 10.0g of the sample to be tested after crushing, accurately w...

Embodiment 2

[0098] This embodiment is an example of detection of the residual solvent, monomer and initiator decomposition products of another tertiary amino methacrylate copolymer in the present invention

[0099] Test product (containing tertiary amino methacrylate copolymer): Guangzhou Maofeng Pharmaceutical Co., Ltd. self-produced methyl methacrylate-diethylaminoethyl methacrylate (55:45) copolymer.

[0100] According to the preparation method of the test solution and the reference solution in Example 1, but the phosphoric acid was replaced with sulfuric acid to prepare the test solution and the reference solution. The calculation is the same as in Example 1.

[0101] Test result: see the test chart of the test solution Picture 9 It can be seen from the figure that the detection method of the present invention can also be applied to the detection of another tertiary amino-containing methacrylate copolymer that is different from Example 1. The residual solvent methanol (5ppm) and ethanol are...

Embodiment 3

[0103] Prepare the solution according to the method in Example 1, prepare the test solution of Guangzhou Maofeng Pharmaceutical Co., Ltd. self-produced E100, add sodium hydroxide solution to adjust the pH to 1.5, 2.5, 3.5, and 5 respectively, and take part of the test product. The solution prepares the reference solution. When pH>5, the precipitation and flocculation in the test solution is difficult to reconstitute and is not applicable, so no comparison was made. Each sample was injected for testing, and another sample was injected 12 hours later. The test results are summarized and compared to the difference in peak area of the test solution and the reference solution. The experimental results are shown in Table 9 and Table 10:

[0104] Table 9 Stability of the test solution under different pH values (peak area comparison table)

[0105]

[0106]

[0107] It can be seen from Table 9 above that the test solution of Example 3 showed no significant change in the peak area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com