A preparation method of zinc or zinc alloy or its composite material tissue engineering scaffold

A technology of tissue engineering scaffolds and composite materials, which is applied in the field of medical material preparation, can solve the problems of difficult preparation, high safety factor requirements, high metal 3D printing costs, etc., and achieves a wide range of pore sizes, uniform distribution of pores, and is conducive to repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

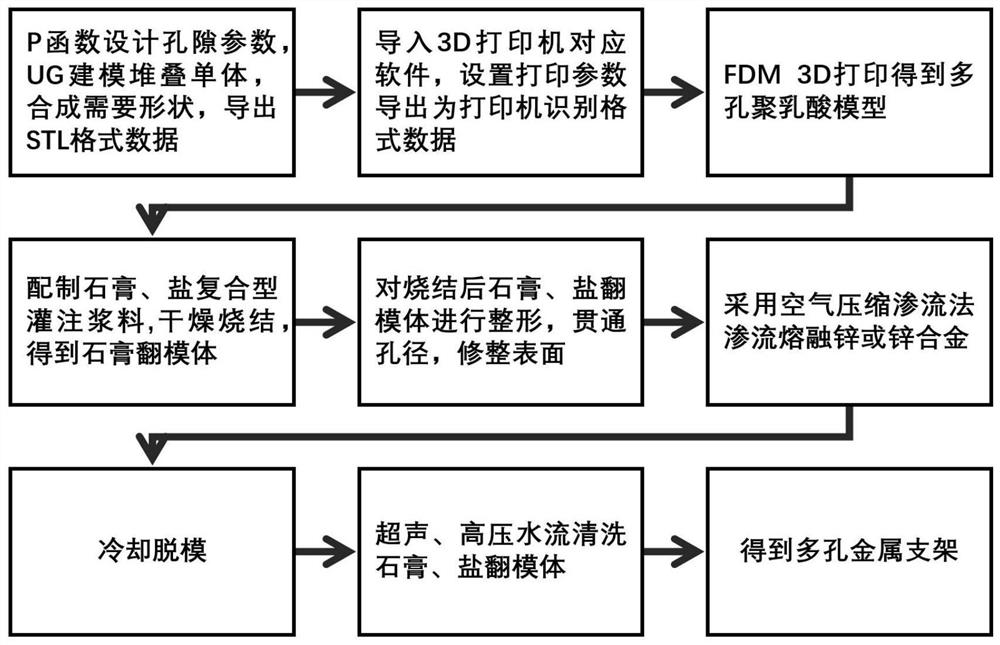

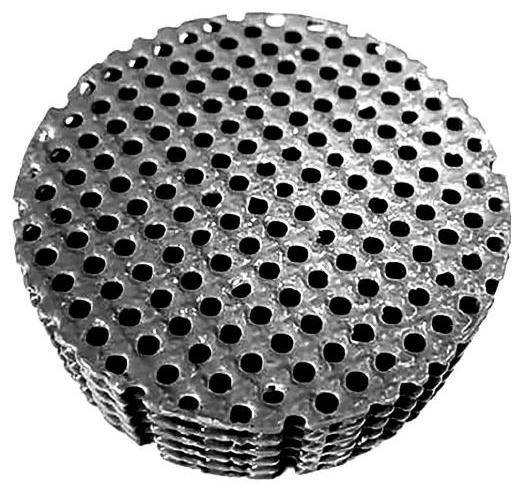

[0027] The invention discloses a preparation method of a pure zinc tissue engineering scaffold, wherein the base material of the tissue engineering scaffold is pure zinc. The polylactic acid model was prepared by FDM3D printing, and then the pure zinc tissue engineering scaffold was prepared by percolation casting after preparing gypsum and salt mold. The steps are as follows:

[0028] 1) Adjust the parameter C in the P function: A=cos(x)+cos(y)+cos(z)+C to -0.5 to obtain a monomer model with a porosity of 64% and a pore size of 1174 μm. Import UG software, stack and cut regularly to obtain a cylindrical porous scaffold body with a diameter of 60mm and a height of 40mm.

[0029] 2) Import the designed stent model into the slicing software corresponding to the FDM3D printer to obtain the printer identification format file. Set the printing temperature and input it into the printer to prepare the polylactic acid porous scaffold. After obtaining the stent body, remove the base...

Embodiment 2

[0035] The invention discloses a preparation method of a pure zinc tissue engineering scaffold, wherein the base material of the tissue engineering scaffold is pure zinc. The polylactic acid model was prepared by FDM3D printing, and then the pure zinc tissue engineering scaffold was prepared by percolation casting after preparing gypsum and salt mold. The steps are as follows:

[0036] 1) Adjust the parameter C in the P function: A=cos(x)+cos(y)+cos(z)+C to 0.25 to obtain a monomer model with a porosity of 42% and a pore size of 645 μm, and import the monomer into UG software, after regular stacking and cutting, a cylindrical porous scaffold body with a diameter of 60mm and a height of 40mm is obtained.

[0037] 2) Import the designed stent model into the slicing software corresponding to the FDM3D printer to obtain the printer identification format file. Set the printing temperature and input it into the printer to prepare the polylactic acid porous scaffold. After the ste...

Embodiment 3

[0043] The invention discloses a preparation method of a pure zinc tissue engineering scaffold, wherein the base material of the tissue engineering scaffold is pure zinc. The polylactic acid model was prepared by FDM3D printing, and then the pure zinc tissue engineering scaffold was prepared by percolation casting after preparing gypsum and salt mold. The steps are as follows:

[0044] 1) Adjust the parameter C in the P function: A=cos(x)+cos(y)+cos(z)+C to 0.5 to obtain a monomer model with a porosity of 35% and a pore size of 240 μm, and import the monomer into UG software, after regular stacking and cutting, a cylindrical porous scaffold body with a diameter of 60mm and a height of 40mm is obtained.

[0045] 2) Import the designed stent model into the slicing software corresponding to the FDM3D printer to obtain the printer identification format file. Set the printing temperature and input it into the printer to prepare the polylactic acid porous scaffold. After the sten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com