A kind of preparation method of se solar cell

A technology of solar cells and products, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of not being able to meet the protection of PSG masks, restricting the application of alkali polishing on the back, and affecting the structure of SE cells, etc., to increase back reflection and back Passivation effect, improve the quality of SE battery, increase the effect of low-temperature phosphorus diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

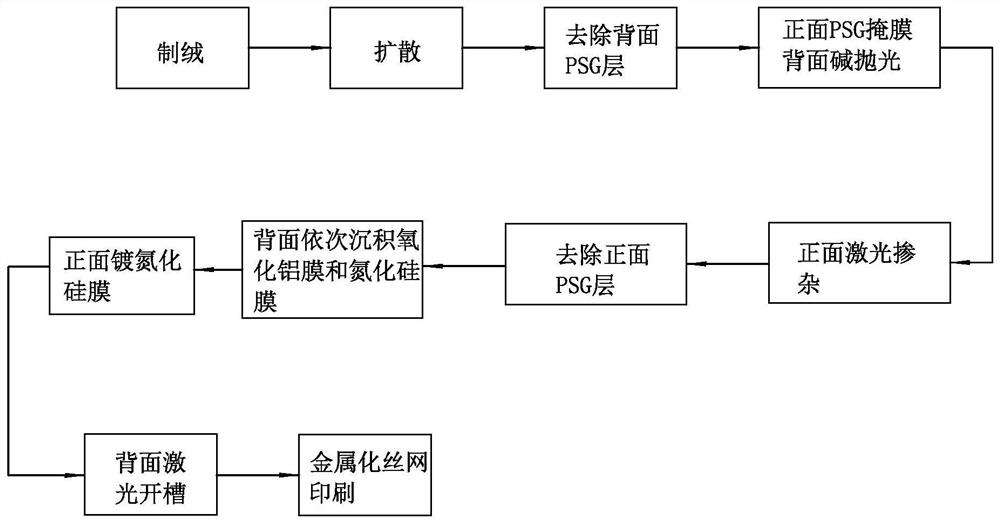

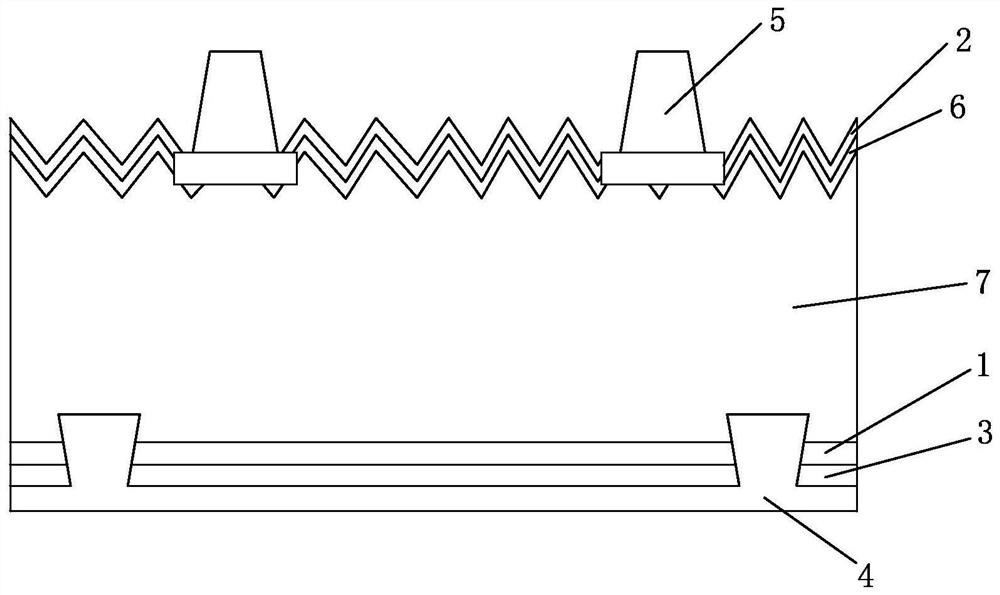

[0038] Such as figure 1 and 2 Shown, is the preparation method of a kind of SE solar cell of the present invention, specifically comprises the following steps:

[0039] S1. Select a lightly doped p-type single crystal silicon wafer 7 (P-type silicon) with a resistivity of 0.1-6Ω·cm, and perform alkali texturing on the P-type silicon to form pyramid-shaped anti-reflection on the front and back sides For the suede surface, the weight loss range of velvet making is 0.4-0.8g, and the reflectivity (full band 300-12000nm) range is 10%-18%.

[0040] S2. Place the product obtained in step S1 in a furnace tube at 500-900° C. for P (phosphorus) diffusion for 5 minutes to 30 minutes to form a PSG layer on the surface of the silicon wafer, that is, to form an N-type emitter 6, and then perform low-temperature P (phosphorus) diffusion. (phosphorus) diffusion, to ensure that there is a certain proportion of phosphorus atoms in PSG, and to provide phosphorus source for laser doping.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com