Bottom mud drying consolidation agent and preparation method thereof

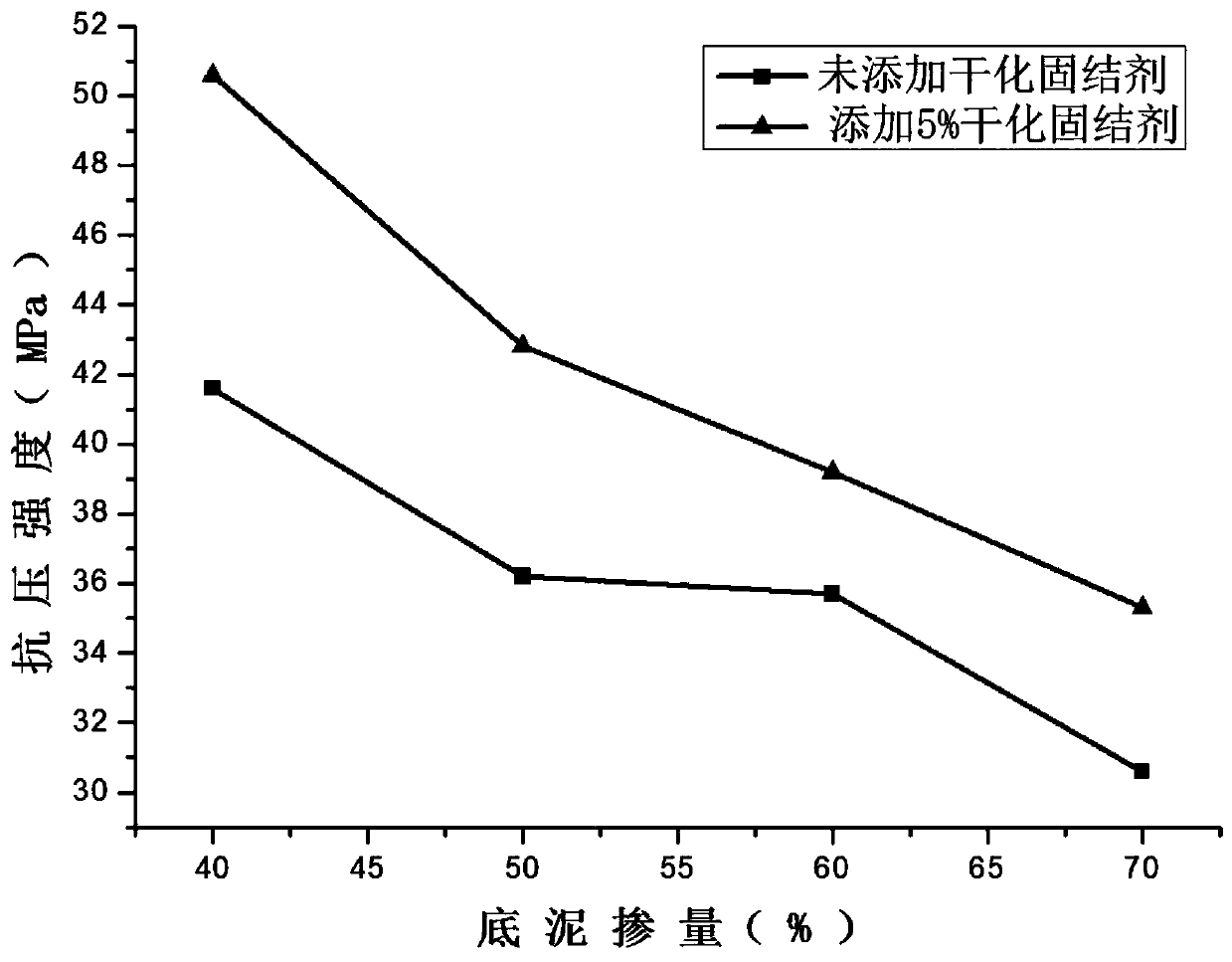

A technology for a consolidating agent and bottom mud, which is applied in the field of bottom mud drying consolidating agent and its preparation, can solve the problem of high drying cost, easy drying efficiency affected by weather and environment, and bottom mud moisture content lower than 20% and other problems, to achieve the effect of reducing water content, contributing to subsequent resource utilization, and improving compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of sediment drying consolidation agent is prepared by the following method:

[0026] A, Soak the high-calcium fly ash selected above in 2.5mol / L sodium hydroxide solution for 2 hours, then fully dry it for later use;

[0027] B, Portland cement, modified fly ash, quicklime, magnesia, soda ash, gypsum powder and microsilica are ground respectively, and passed through a 100-mesh sieve;

[0028] C. Weigh 50% of Portland cement, 20% of modified fly ash, 15% of quicklime, 8% of magnesium oxide, 2% of soda ash, 3% of gypsum powder, and 2% of microsilica powder according to mass percentage, and mix them uniformly to obtain Drying agent.

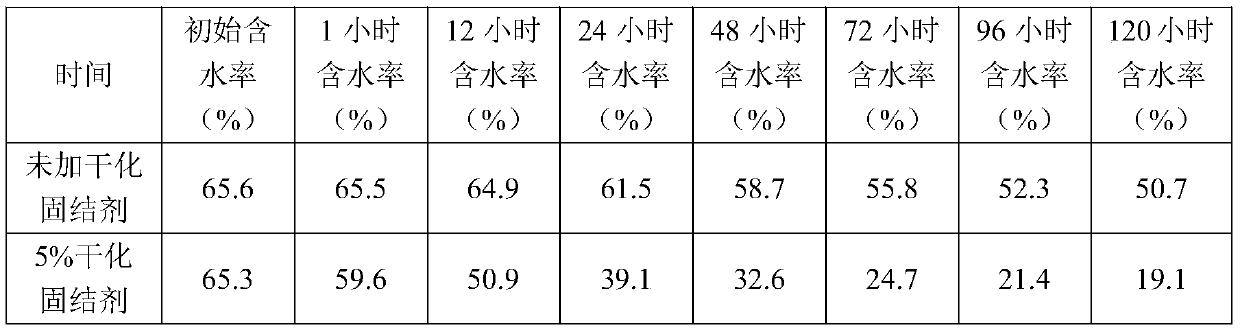

[0029] The prepared sediment drying and consolidating agent was used to dredge the sediment of a natural river in Shanghai. The initial water content of described bottom mud is about 65%, and the mass mixing ratio of drying consolidating agent is 5% (that is, consolidating agent accounts for 5% of the total mass of required dried bot...

Embodiment 2

[0035] A kind of sediment drying consolidation agent is prepared by the following method:

[0036] A. Soak the high-calcium fly ash in 1mol / L sodium hydroxide solution for 2 hours, then fully dry it for later use;

[0037] B, Portland cement, modified fly ash, quicklime, magnesia, soda ash, gypsum powder and microsilica are ground respectively, and passed through a 100-mesh sieve;

[0038] C. Take 38% of Portland cement, 30% of modified fly ash, 10.5% of quicklime, 15% of magnesium oxide, 0.5% of soda ash, 5% of gypsum powder, and 1% of microsilica powder according to mass percentage, and mix them evenly to obtain Drying agent.

[0039]The dried consolidating agent prepared in Example 2 is used for the construction mud produced in the construction process of a construction site in Shanghai, the water content of the mud is about 50%, and the mass ratio of the consolidating agent is 3% (i.e. Consolidation agent accounted for 3% of the total mass of the required dried bottom mu...

Embodiment 3

[0045] A dry curing agent is prepared by the following method:

[0046] A, Soak the high-calcium fly ash in 3mol / L sodium hydroxide solution for 2 hours, then fully dry it for later use;

[0047] B, Portland cement, modified fly ash, quicklime, magnesium oxide, soda ash, gypsum powder and microsilica powder are respectively ground until they can pass through a 100-mesh sieve;

[0048] C. Take 60% of Portland cement, 15% of modified fly ash, 15% of quicklime, 5% of magnesium oxide, 2% of soda ash, 2% of gypsum powder, and 1% of silica fume according to the mass percentage, and mix them evenly to obtain Drying agent.

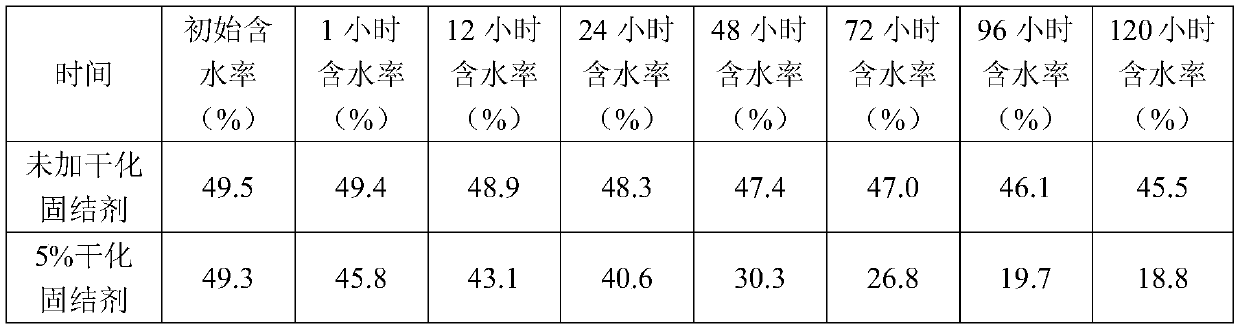

[0049] The dry consolidating agent prepared in Example 3 was used to dredge the sediment of a natural river in the old urban area of Suzhou. The sediment had been dehydrated by a plate and frame filter press, and the moisture content after dehydration was about 50%. The consolidating agent The mixing ratio is 5% (that is, the consolidation agent accounts for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com