Charcoal-based nitrogen-enriched composite material as well as preparation and application thereof

A composite material and biochar technology, applied in other chemical processes, chemical instruments and methods, separation methods, etc., can solve problems such as insufficient intermolecular adsorption retention, insufficient hardness of metal-organic frameworks, and poor carbon dioxide adsorption effects, etc., to achieve Excellent carbon dioxide adsorption capacity, improved physical and chemical properties, and reduced impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a biochar-based nitrogen-enriched composite material, comprising the following steps:

[0032] (1) pyrolyzing the biomass to obtain biochar;

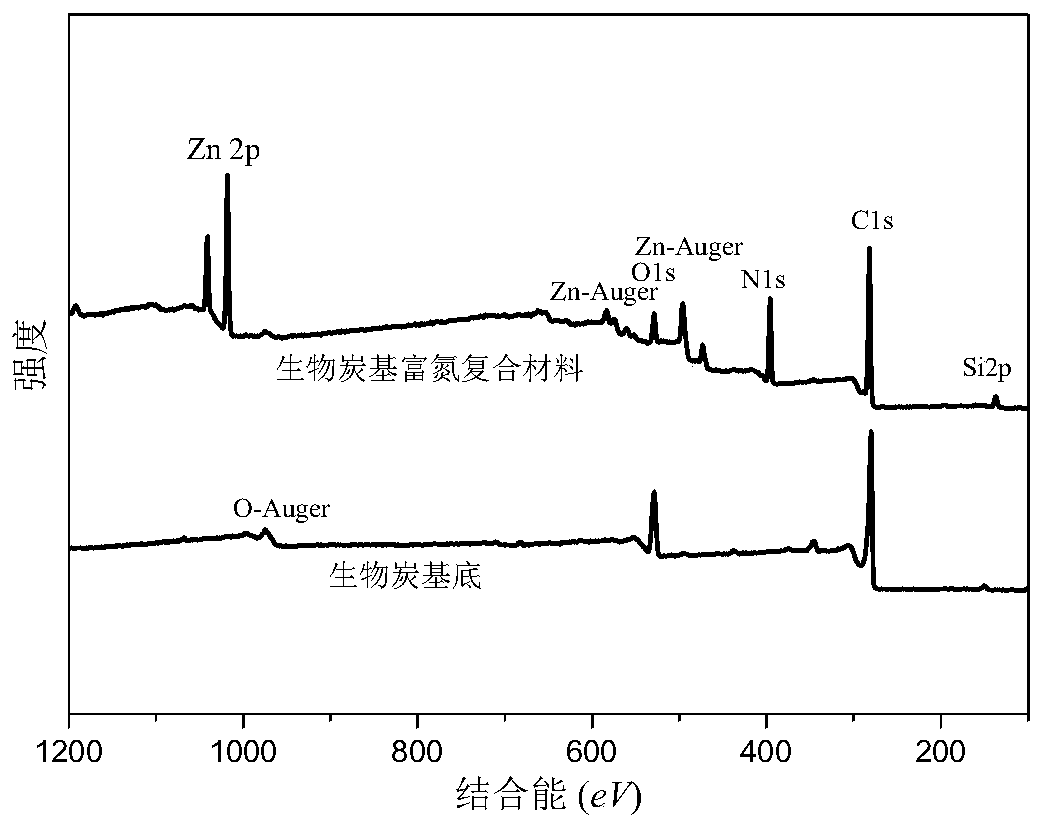

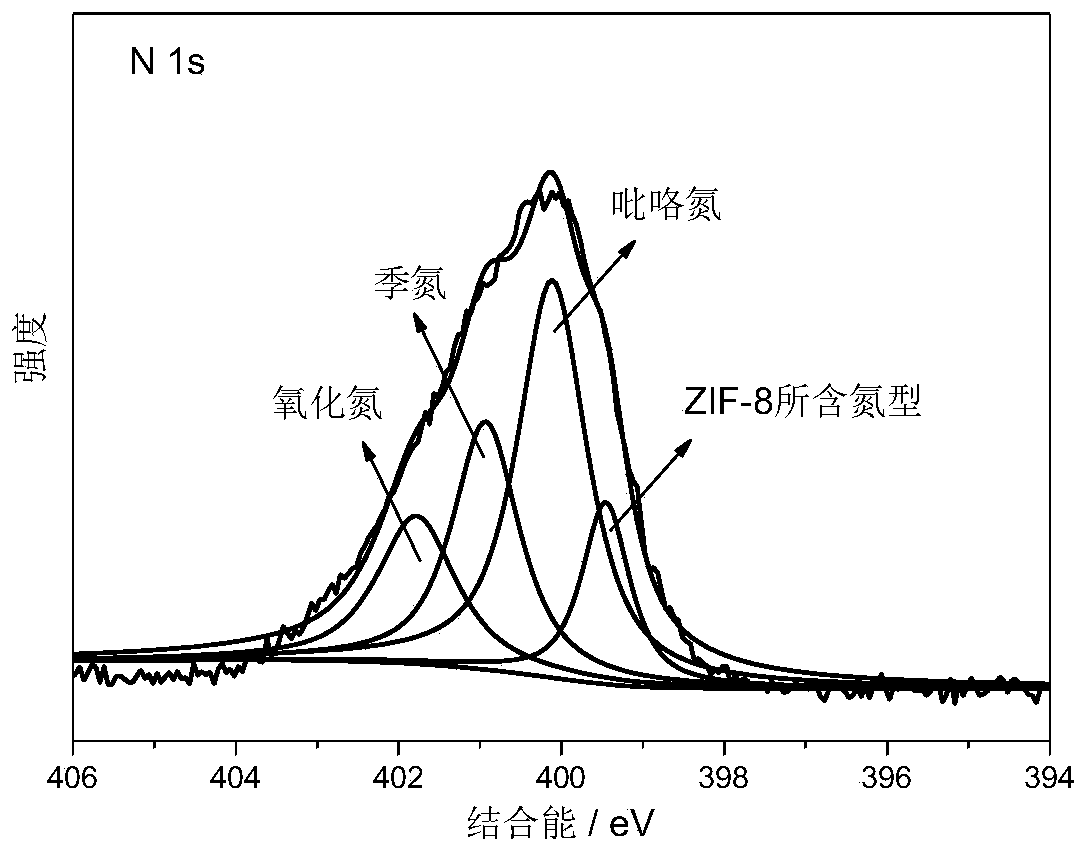

[0033] (2) Mix the metal organic framework material precursor solution with the biochar obtained in step (1) to obtain a mixed solution; the metal organic framework material precursor solution includes a metal salt solution obtained by dissolving a metal salt in a solvent and an organic ligand The organic ligand solution obtained by dissolving the body in a solvent, and the organic ligand contains nitrogen element;

[0034] (3) reacting the mixed solution described in step (2) under stirring conditions, so that it synthesizes a metal-organic framework material in situ on the surface of biochar; after the reaction is completed, the solid-liquid is separated, and the obtained solid is washed and dried to obtain the described Biochar-based nitrogen-enriched composites.

[0035] In some...

Embodiment 1

[0051] A preparation method of a biochar-based nitrogen-rich composite material, comprising the steps of:

[0052] (1) Pyrolyze bamboo chips, the atmosphere is carbon dioxide, the flow rate is 100mL / min, the heating rate is 10°C min, the pyrolysis temperature is 700°C, and the residence time is 1h;

[0053] (2) Dissolving zinc nitrate hexahydrate and 2-methylimidazole respectively in an organic solution and mixing, the organic solvent is methanol, and the mass ratio is 1:5:10;

[0054] (3) adding the biochar prepared in step 1 to the mixed solution prepared in step 2, fully mixing, and the mixing method is ultrasonic treatment;

[0055] (4) Put the mixed solution prepared in step 3 into a reactor with a stirrer to synthesize MOF in situ, the heating rate is 10°C / min, the reaction temperature is 40°C, the reaction time is 9h, and the stirring rate is 600rpm .

[0056] (5) After cooling, the solid obtained in step 4 was collected by centrifugation, and washed 3 times with fres...

Embodiment 2

[0069] A preparation method of a biochar-based nitrogen-rich composite material, comprising the steps of:

[0070] (1) Pyrolyze sawdust, the atmosphere is carbon dioxide, the flow rate is 50mL / min, the heating rate is 5°C min, the pyrolysis temperature is 400°C, and the residence time is 0.5h;

[0071] (2) Dissolving and mixing cobalt nitrate hexahydrate and 2-methylimidazole in an organic solution, the organic solvent is N,N-dimethylformamide, and the mass ratio is 1:1:5;

[0072] (3) adding the biochar prepared in step 1 to the mixed solution prepared in step 2, fully mixing, and the mixing method is ultrasonic treatment;

[0073] (4) Put the mixed solution prepared in step 3 into a reactor with a stirrer to synthesize MOF in situ, the heating rate is 10°C / min, the reaction temperature is 20°C, the reaction time is 9h, and the stirring rate is 1000rpm .

[0074] (5) After cooling, the solid obtained in step 4 was collected by centrifugation, and washed 3 times with fresh m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com