Ordered base al 1-x ga x Controllable epitaxial growth method of n quantum dots

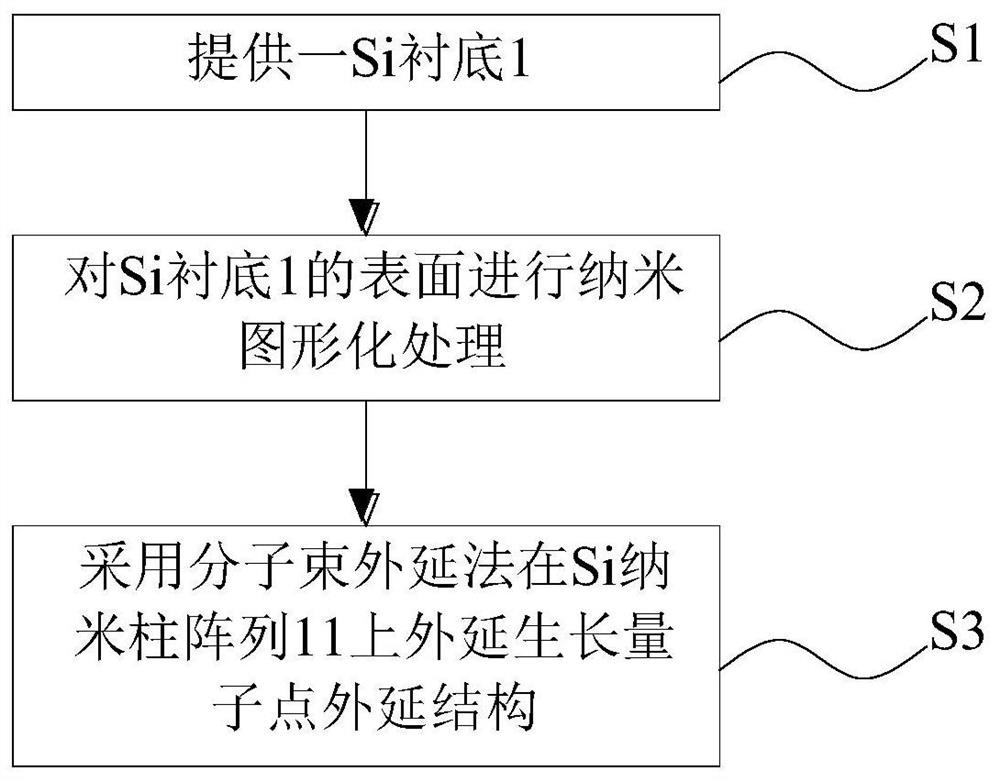

An epitaxial growth, quantum dot technology, applied in electrical components, nanotechnology, circuits, etc., can solve the problems of difficult nanopillars and quantum dot distribution and structure control, achieve enhanced light extraction efficiency, facilitate large-scale processing, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] First, take a piece of Si substrate, wash the surface of Si substrate with acetone and ethanol solution for 10 minutes, and place it in an oxygen ion environment for 10 minutes to complete the hydrophilic treatment.

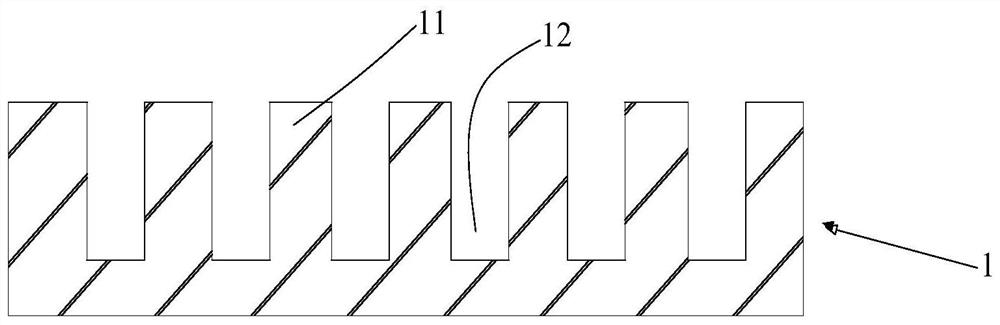

[0062] Then, a nano-patterning treatment is performed on the Si substrate by using a nano-sphere etching process.

[0063] Specifically, in the first step, a layer of uniformly dispersed PS nanosphere film 1a is prepared on the surface of Si substrate 1 by self-assembly process, and the diameter of PS nanosphere is 500nm, such as Figure 10 As shown; the second step is to etch the PS nanospheres with oxygen plasma in the glue remover to reduce their diameter, and form a nanosphere mask 1b on the surface of the Si substrate 1, such as Figure 11 with Figure 14 Shown; the third step, use reactive ion etching (abbreviated as RIE) to etch the Si substrate 1 with nanosphere mask 1b for about 2min, and the Si substrate 1 between PS nanospheres is etched away t...

Embodiment 2

[0071] First, take a piece of Si substrate, wash the surface of Si substrate with acetone and ethanol solution for 10 minutes, and place it in an oxygen ion environment for 15 minutes to complete the hydrophilic treatment.

[0072] Then, a nano-patterning treatment is performed on the Si substrate by using a nano-sphere etching process.

[0073] Specifically, the first step is to prepare a uniformly dispersed PS nanosphere solution. The specific method is to use a micropipette to measure the PS nanosphere dispersion (10% by mass, and the diameter of the PS nanosphere is 200nm) and absolute ethanol The solution was placed in a small beaker, the volume ratio of the two was 1:2, and the solution was ultrasonically dispersed for 10 minutes to obtain a uniformly dispersed PS nanosphere solution; in the second step, PS nanospheres were pre-assembled on the water surface, specifically The method is to prepare a petri dish filled with deionized water (the surface area of the water i...

Embodiment 3

[0082] First, take a piece of Si substrate, wash the surface of the Si substrate with acetone and ethanol solution for 12 minutes, and place it in an oxygen ion environment for 12 minutes to complete the hydrophilic treatment.

[0083] Then, a nano-patterning process is performed on the Si substrate by using a nano-imprint process.

[0084] Specifically, in the first step, a layer of embossing glue 1c is coated on the surface of Si substrate 1, such as Figure 18 As shown; the second step is to use a mold to transfer the nanometer pattern to the imprinting glue 1c, and its pattern is a round column arranged in a square, with a diameter of 50nm and a spacing of 200nm, and it is cured with an ultraviolet light source and placed on the Si substrate 1 Form the imprint glue mask 1d, such as Figure 19 Shown; the third step is to etch the Si substrate 1 with the imprinting rubber mask 1d by ICP, the etching depth is 400nm, and the Si substrate 1 between the imprinting rubber mask 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com