Hydrogel vascular embolism material and shape memory embolism treatment method

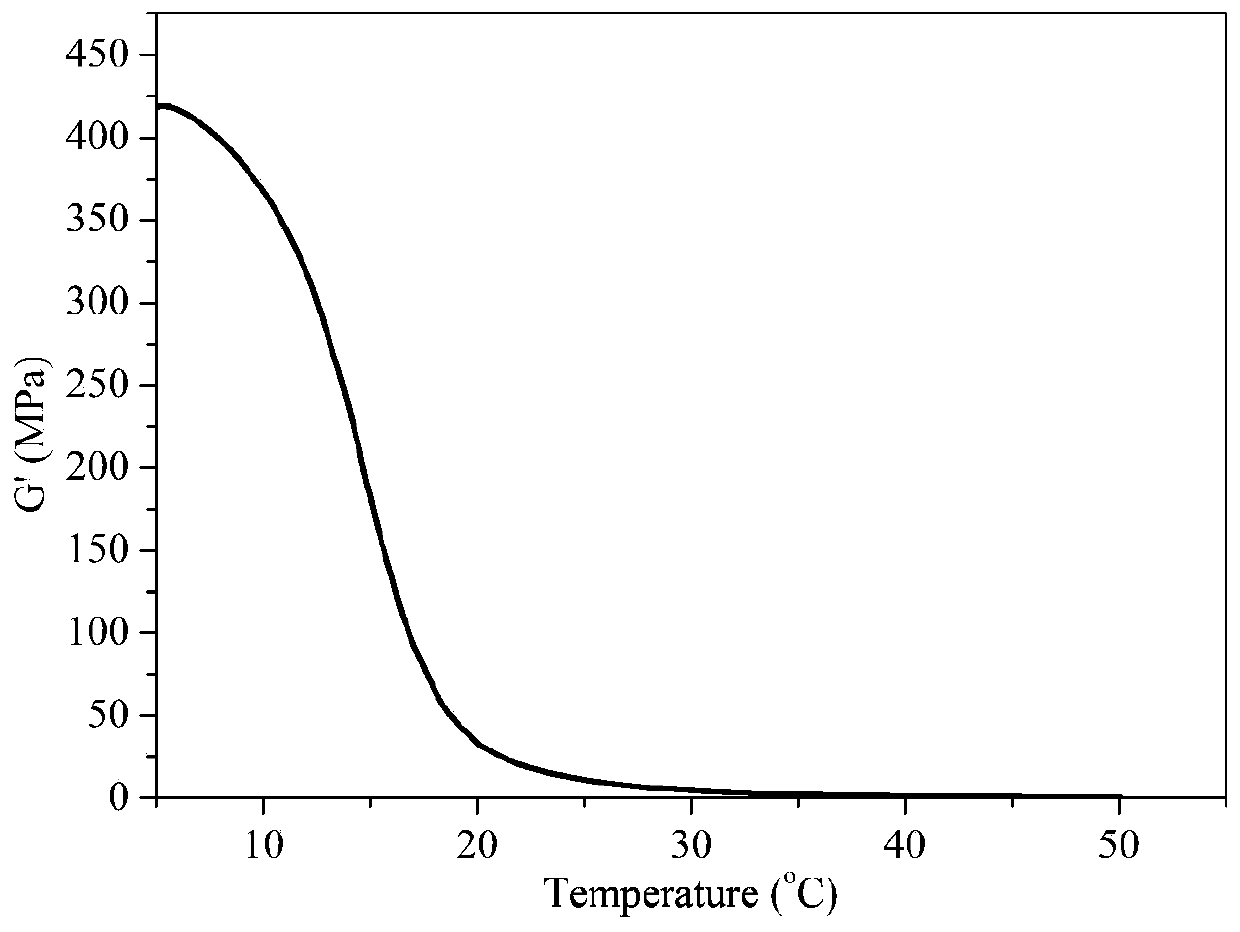

A technology of vascular embolization and treatment method, which is applied in the field of hydrogel vascular embolization materials and its preparation, which can solve the problems of incompact embolization, high cost, and high recanalization rate of blood vessels, and achieve excellent temperature-responsive shape memory characteristics and low preparation costs , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 7.3910 g of 2-phenoxyethyl acrylate, 1.8147 g of acrylamide, and 0.0230 g of polyethylene glycol diacrylate (molecular weight=700) were dissolved in 8.47 g of dimethylsulfoxide. After being fully dissolved, argon gas was continuously passed into the solution for 30 minutes to remove oxygen in the solution, and then 0.0316 g of azobisisoheptanonitrile was added to the solution and fully dissolved to obtain a gel precursor solution.

[0036] Inject the gel precursor solution into a cylindrical mold (inner diameter = 3.0mm), seal the mold and place it in an incubator, adjust the temperature of the incubator to 50°C to thermally initiate monomer polymerization, and continue the reaction for 10 hours. Columnar organogels based on sulfoxide as solvent.

[0037] Take the columnar organogel out of the mold and replace it with water 50 times the mass of the organogel, and replace the water every 12 hours for 10 consecutive days to fully replace dimethyl sulfoxide with water, and...

Embodiment 2

[0042]4.9219 g of 2-phenoxyethyl acrylate, 2.7294 g of acrylamide, and 0.0229 g of polyethylene glycol diacrylate (molecular weight=700) were dissolved in 9.90 g of dimethylsulfoxide. After fully dissolving, argon gas was continuously passed into the solution for 30 minutes to remove oxygen in the solution, and then 0.0321 g of azobisisoheptanonitrile was added to the solution and fully dissolved to obtain a gel precursor solution.

[0043] Inject the gel precursor solution into a cylindrical mold (inner diameter = 3.0mm), seal the mold and place it in an incubator, adjust the temperature of the incubator to 50°C to thermally initiate monomer polymerization, and continue the reaction for 10 hours. Columnar organogels based on sulfoxide as solvent.

[0044] Take the columnar organogel out of the mold and replace it with water 50 times the mass of the organogel, and replace the water every 12 hours for 10 consecutive days to fully replace dimethyl sulfoxide with water, and then ...

Embodiment 3

[0047] 1.2301 g of 2-phenoxyethyl acrylate, 4.0961 g of acrylamide, and 0.0228 g of polyethylene glycol diacrylate (molecular weight=700) were dissolved in 12.21 g of dimethylsulfoxide. After being fully dissolved, argon gas was continuously passed into the solution for 30 minutes to remove oxygen in the solution, and then 0.0322 g of azobisisoheptanonitrile was added to the solution and fully dissolved to obtain a gel precursor solution.

[0048] Inject the gel precursor solution into a cylindrical mold (inner diameter = 3.0mm), seal the mold and place it in an incubator, adjust the temperature of the incubator to 50°C to thermally initiate monomer polymerization, and continue the reaction for 10 hours. Columnar organogels based on sulfoxide as solvent.

[0049] Take the columnar organogel out of the mold and replace it with water 50 times the mass of the organogel, and replace the water every 12 hours for 10 consecutive days to fully replace dimethyl sulfoxide with water, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

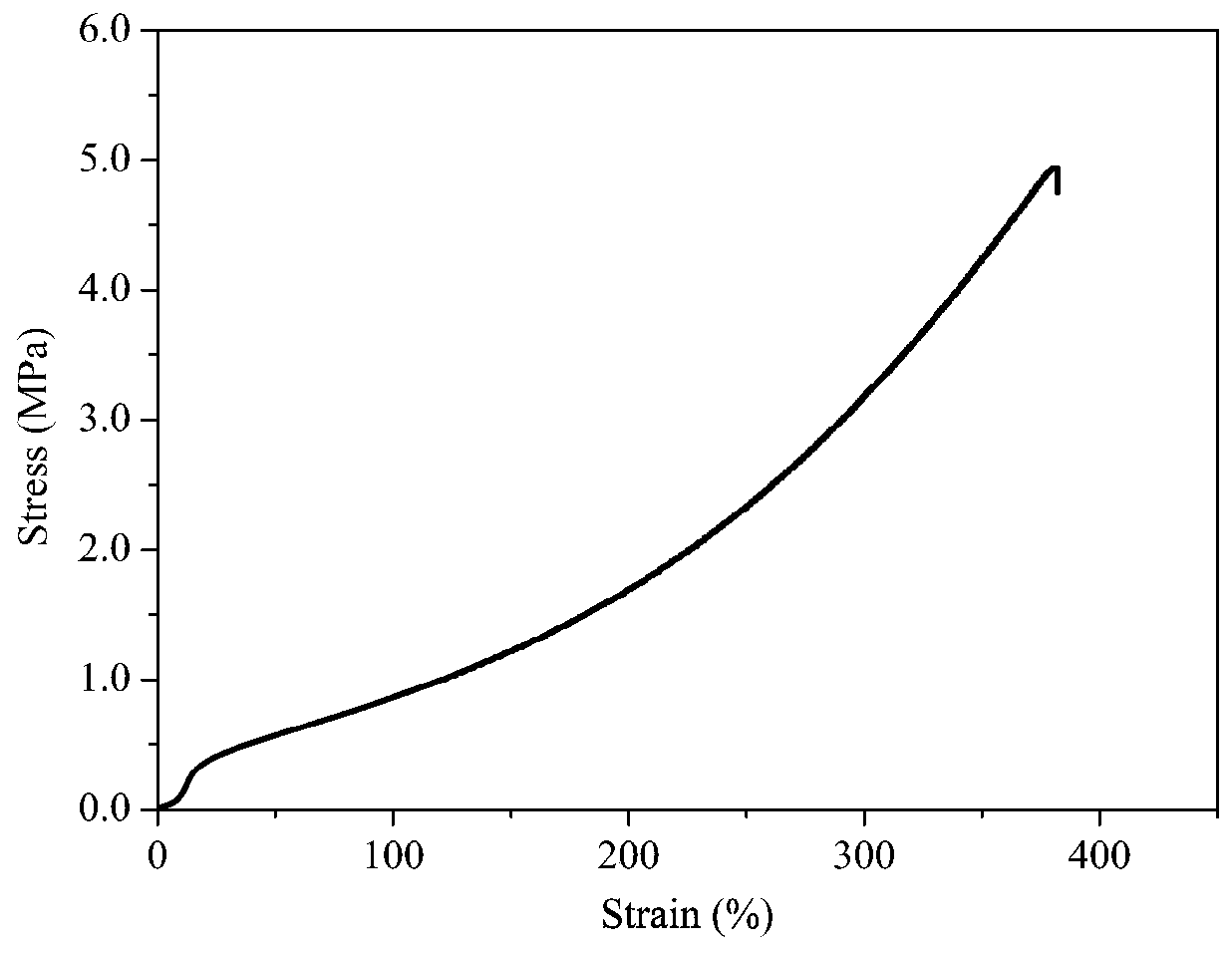

| tensile strength | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com